Pressure sensitive element based on thermoplastic elastomers and surface load distribution measurement method

A technology of thermoplastic elastomers and pressure-sensitive components, applied in the direction of measuring force, measuring devices, instruments, etc., can solve problems such as poor repeatability, low measurement sensitivity, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

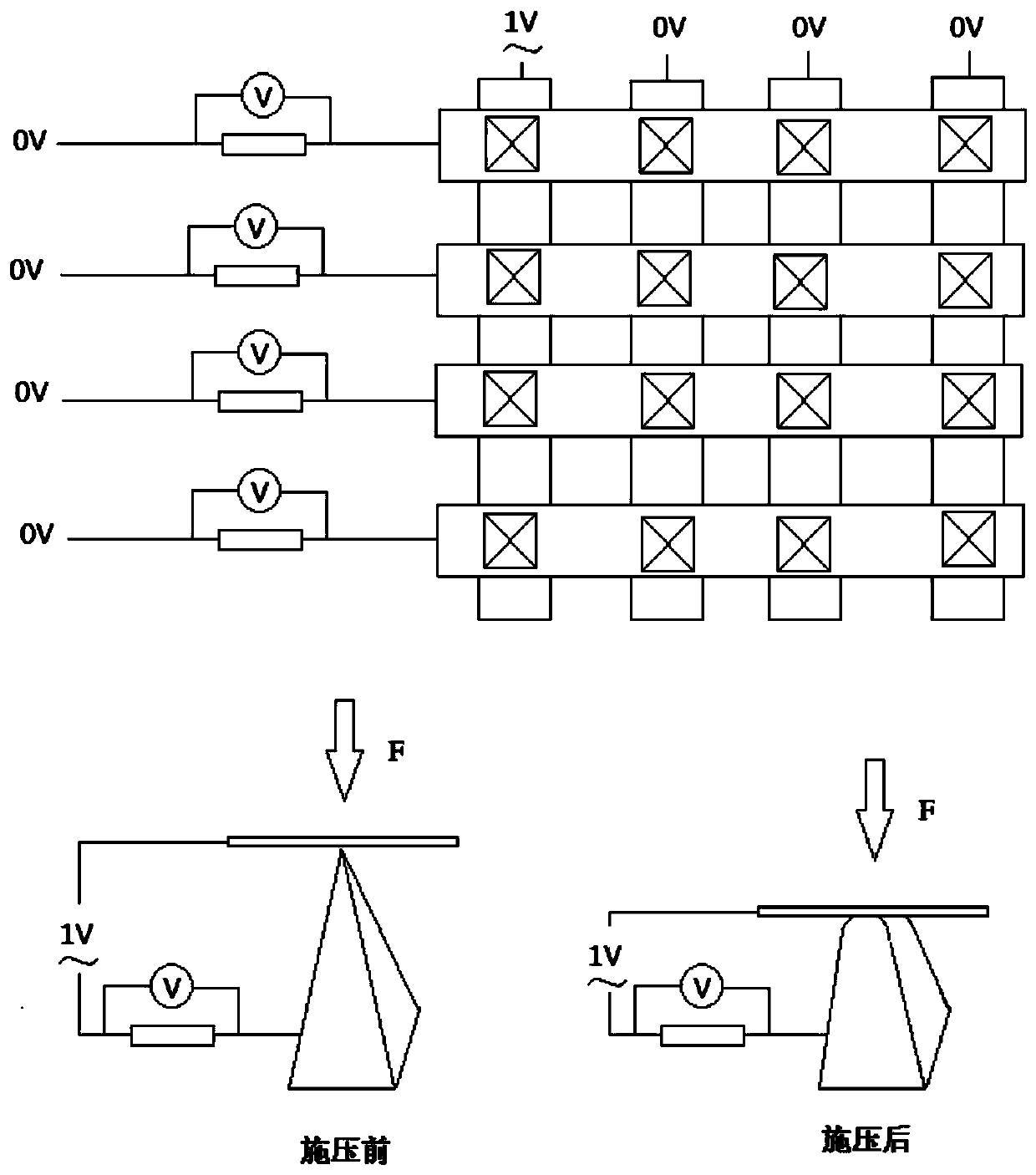

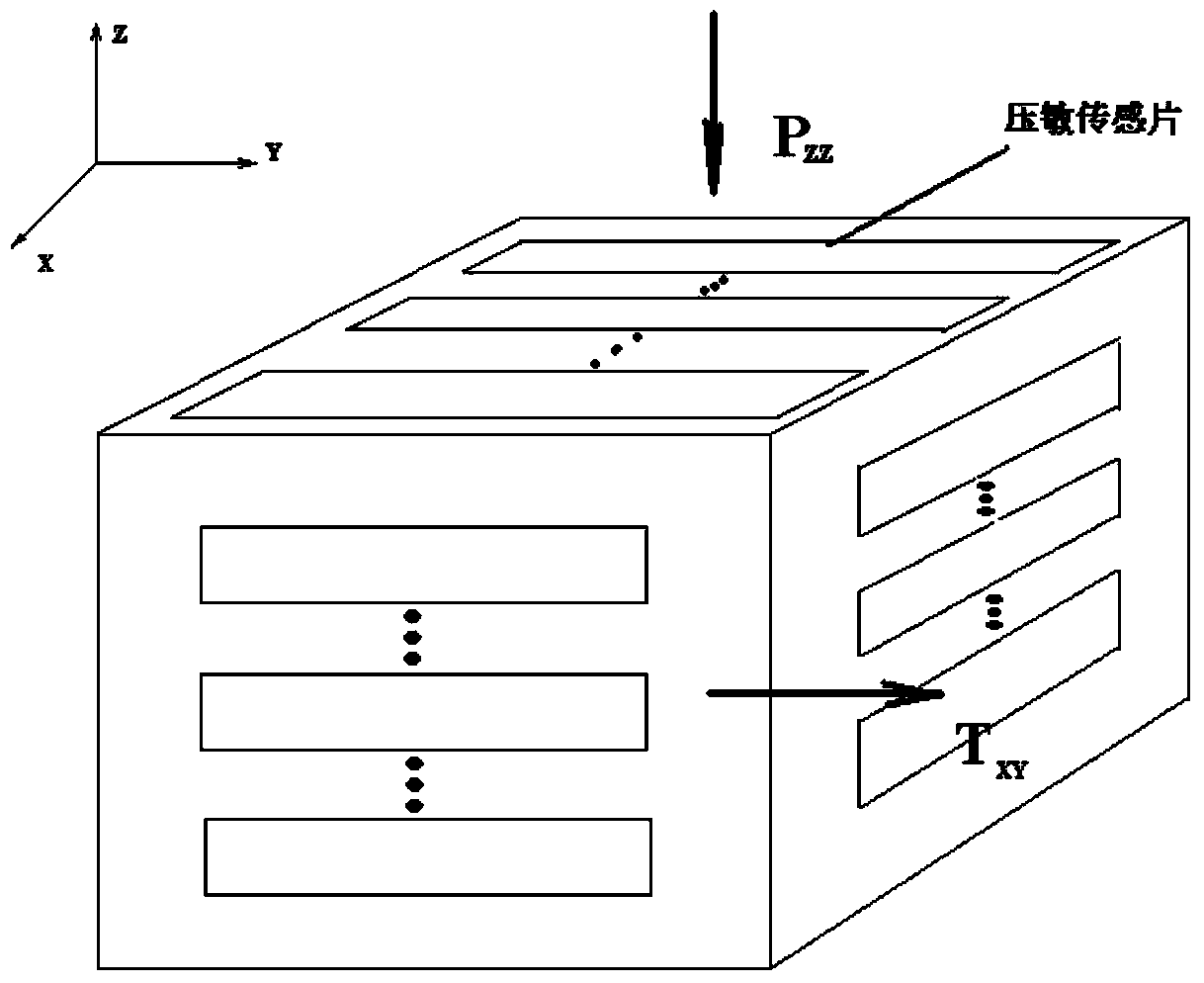

Method used

Image

Examples

Embodiment 1

[0045] Prepare silicon wafer template:

[0046] The thickness of the silicon wafer is 3mm, and the surface thermally oxidized silicon wafer is used for the preparation of the template silicon wafer. The thickness of the oxide layer is 100 to 500nm, and the crystal orientation is . The ordinary negative photolithography method is used. Form a periodic square window on the silicon surface to remove the oxide layer, the window size is 100 μm, fully corrode the window area with tetramethylammonium hydroxide (20% mass ratio) aqueous solution in isopropanol (1:1 volume ratio) at 70 ° C Silicon layer, stop when the tip platform is less than 3μm, etch the cone pit array and use it as a mold.

[0047] Prepare periodic pyramid cones:

[0048] BASF thermoplastic polyurethane transparent prefabricated sheet is used, with a thickness of 1mm and a Shore hardness of A60. Cover the above-mentioned polyurethane prefabricated sheet on the surface of the silicon mold, use a flat pressurized fi...

Embodiment 2

[0058] A conductive polymer is used as a transparent conductive layer, and a polyaniline film with uniform thickness is deposited on the surface of a pyramidal cone array by an in-situ polymerization method.

[0059] Dissolve 4.7 grams of aniline and 3.8 grams of ammonium persulfate in 100 ml of 0.4M HCl solution, soak the polyurethane film with a pyramid structure on the surface for 2 hours, put it into the aniline solution after cleaning, and pour ammonium persulfate into it Solution, keep stirring, the above mixed solution is maintained at 4°C, take out the polyurethane film after stirring for 30 minutes, wash it with deionized water, put it in 1M HCl solution, take it out after 10 hours, and dry it.

[0060] The thickness of the polyaniline film prepared by the above method is about 80nm, the transmittance of visible light is greater than 70%, and the resistivity is about 500Ω·cm. The film is well combined with the polyurethane, and the repeated deformation durability is h...

Embodiment 3

[0063] The BASF thermoplastic polyaniline elastomer transparent prefabricated sheet is used, the thickness is 1mm, and the Shore hardness is A60. Cover the above-mentioned polyaniline prefabricated sheet on the surface of the silicon mold, use a flat pressurized fixture, press the thick film and the silicon mold to be bonded, the stress is 0.1 to 0.5MPa, vacuum heating, the vacuum degree is lower than 10torr, and the temperature is 150±3 ℃, keep it for 20 minutes, slowly cool down, demould, and make a pyramid-cone periodic structure on the surface of transparent polyaniline.

[0064] The template preparation method, the conductive film preparation method, the counter electrode preparation method, and the measurement method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com