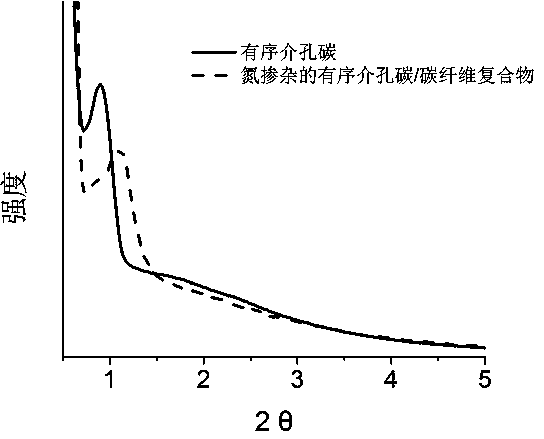

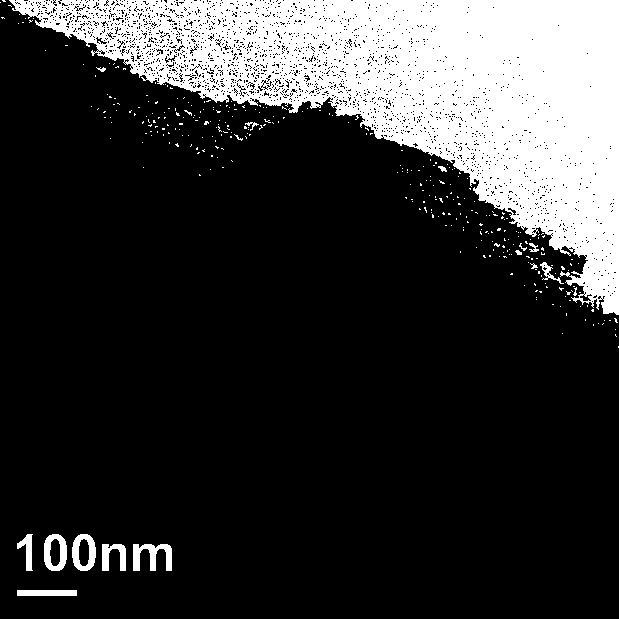

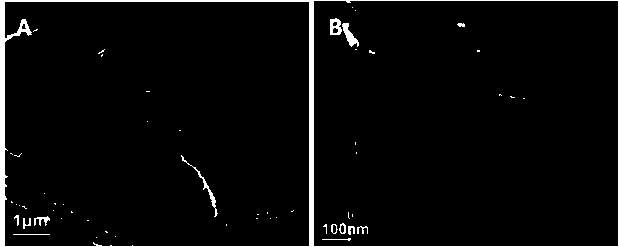

Preparation method for nitrogen-doped ordered mesoporous carbon/carbon fiber composite material

A composite material and mesoporous carbon technology, which is applied in the direction of hybrid capacitor electrodes, can solve the problems of unfavorable electrolyte transmission, easy collapse of mesoporous carbon channels, and low specific surface area, so as to improve electrochemical performance and use less reagents and dosage , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation process and steps of the nitrogen-doped ordered mesoporous carbon / carbon fiber composite material in this example are as follows:

[0026] a. Preparation of phenolic resin prepolymer

[0027] Put 0.61g of phenol into a round bottom flask, stir and dissolve in a water bath at 40-42°C, then add 0.13g of 20wt% NaOH aqueous solution, stir for 10min, add 1.05g of 37wt% formaldehyde solution, and then heat up to 70- Stir and react at 75°C for 1 hour, lower to room temperature, then add 0.6M HCl solution dropwise, adjust the pH value of the solution to 7.0, remove water under vacuum and reduce pressure below 50°C, and dissolve the obtained viscous liquid in absolute ethanol to prepare The solution of 20wt% is standby;

[0028] b. Preparation of ordered mesoporous carbon / carbon fiber composites with self-supporting coaxial structure

[0029] Dissolve 1.6g of triblock copolymer F127 in a mixed solution of 8g of ethanol and 1g of 0.2M hydrochloric acid, stir at ...

Embodiment 2

[0031] The difference between this embodiment and Example 1 is that the self-supporting material in step b is polyacrylonitrile-based carbon fiber. Other steps and parameters are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com