Graphite-polytetrafluoroethylene three-dimensional particle cathode of MFC (microbial fuel cell) synthesized on basis of hydrogen peroxide and preparation method

A polytetrafluoroethylene and graphite technology, used in battery electrodes, biochemical fuel cells, electrical components, etc., can solve problems such as low hydrogen peroxide yield, improve mass transfer coefficient and energy output, increase production, and high conductivity. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

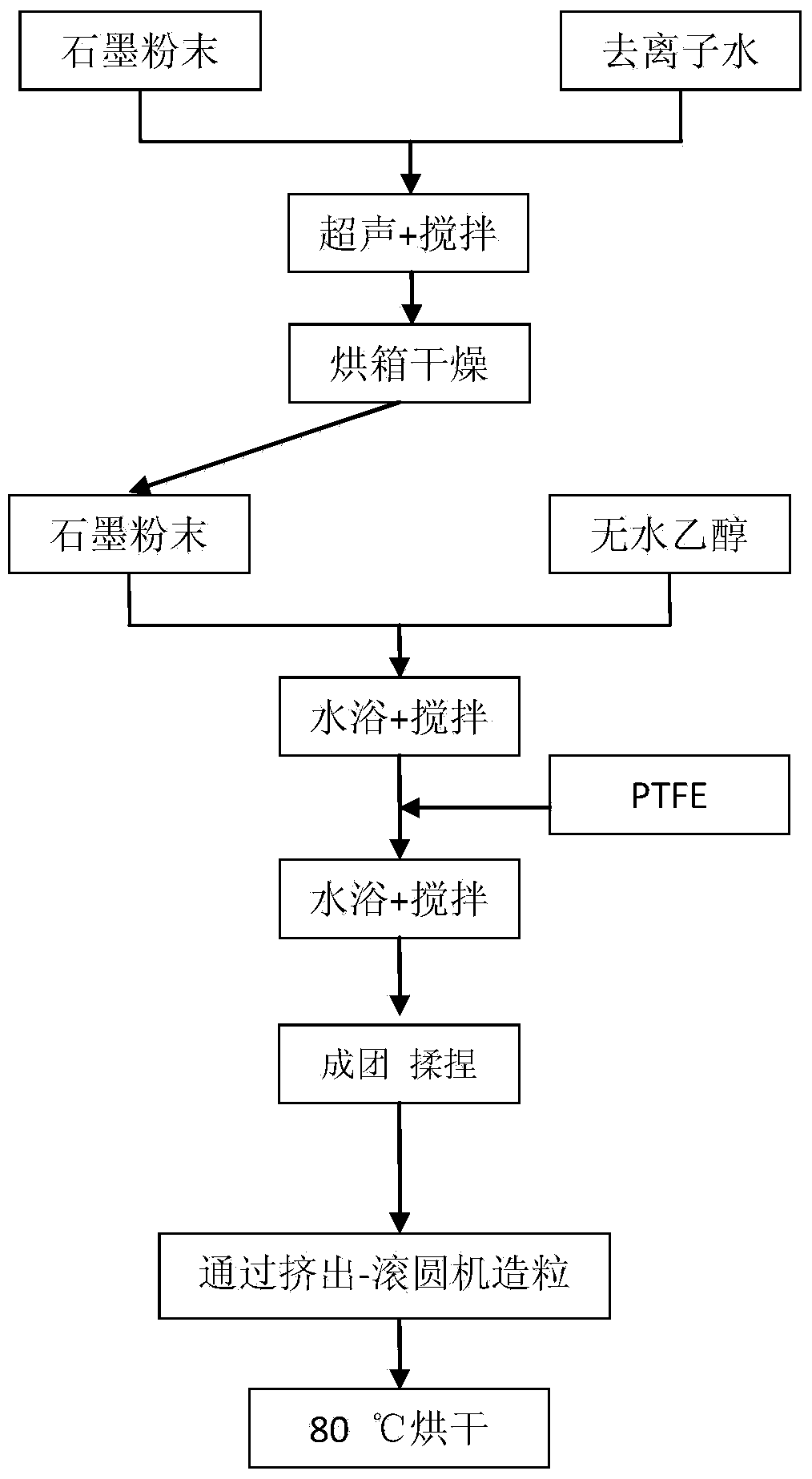

[0020] (1) Soak graphite powder (with a particle size of about 20-40 μm) in deionized water, and clean it ultrasonically for 30 minutes at 30°C; then put the graphite powder in an oven at 80°C for drying; dry the dried graphite powder Place in a container, add ethanol to immerse it, and stir for 60 minutes in a water bath at 60°C to disperse the graphite powder in ethanol to form a graphite ethanol dispersion system;

[0021] (2) Under the condition of 60°C water bath and stirring, according to the proportion of 75 μL polytetrafluoroethylene (PTFE, 60wt%) suspension per gram of graphite powder, add the PTFE suspension dropwise to the graphite ethanol dispersion system; in a water bath at 60°C, continue to stir until an elastic graphite-PTFE mixture is formed;

[0022] (3) graphite-polytetrafluoroethylene mixture is prepared the graphite-polytetrafluoroethylene particle that particle diameter is 2-3mm by extruding-spheronization method; Heat and dry at 80°C to remove residual ...

Embodiment 2

[0024] (1) Soak graphite powder (with a particle size of about 40-60 μm) in deionized water, and clean it ultrasonically for 40 minutes at 20°C; then put the graphite powder into an oven at 80°C for drying; dry the dried graphite powder Place in a container, add ethanol to immerse it, and stir for 60 minutes in a water bath at 60°C to disperse the graphite powder in ethanol to form a graphite ethanol dispersion system;

[0025] (2) Under the condition of 60°C water bath and stirring, according to the dosage of 100 μL polytetrafluoroethylene (PTFE, 60wt%) suspension per gram of graphite powder, add the PTFE suspension dropwise to the graphite ethanol dispersion system; In a water bath at 60°C, continue to stir until an elastic graphite-PTFE mixture is formed;

[0026] (3) graphite-polytetrafluoroethylene mixture is prepared the graphite-polytetrafluoroethylene particle that particle diameter is 2-3mm by extruding-spheronization method; Heat and dry at 80°C to remove residual e...

Embodiment 3

[0028] (1) Soak graphite powder (with a particle size of about 10-20 μm) in deionized water, and ultrasonically clean it for 50 minutes at 40°C; then put the graphite powder in an oven at 70°C for drying; dry the dried graphite powder Place in a container, add ethanol to submerge it, and stir for 90 minutes in a water bath at 80°C to disperse the graphite powder in ethanol to form a graphite ethanol dispersion system;

[0029] (2) Under the condition of 80°C water bath and stirring, according to the dosage of 85 μL polytetrafluoroethylene (PTFE, 60wt%) suspension per gram of graphite powder, add the PTFE suspension dropwise to the graphite ethanol dispersion system; In a water bath at 80°C, continue to stir until an elastic graphite-PTFE mixture is formed;

[0030] (3) graphite-polytetrafluoroethylene mixture is prepared the graphite-polytetrafluoroethylene particle that particle diameter is 2-3mm by extruding-spheronization method; Heat and dry at 70°C to remove residual eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com