Preparation method of homogeneous enhanced cellulose acetate hollow fiber membrane

A technology of cellulose acetate and homogeneous reinforcement, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of environmental secondary pollution, poor biocompatibility, and difficult natural degradation, etc., and achieve high peeling Strength, high breaking strength, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

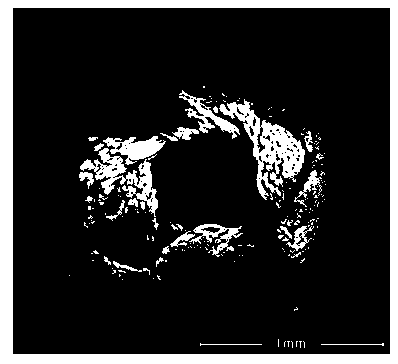

[0017] A homogeneous reinforced cellulose acetate hollow fiber membrane designed by the present invention (referred to as hollow membrane, see figure 1 , 2 ) Preparation method (referred to as preparation method), the preparation method adopts the following process steps:

[0018] (1) Preparation of hollow braided tube reinforcement: using two-dimensional weaving technology to weave cellulose acetate filaments into a hollow braided tube with a diameter of 1-2mm, and use the hollow braided tube as a hollow fiber membrane reinforcement; The two-dimensional weaving technique described is a well-known technique itself.

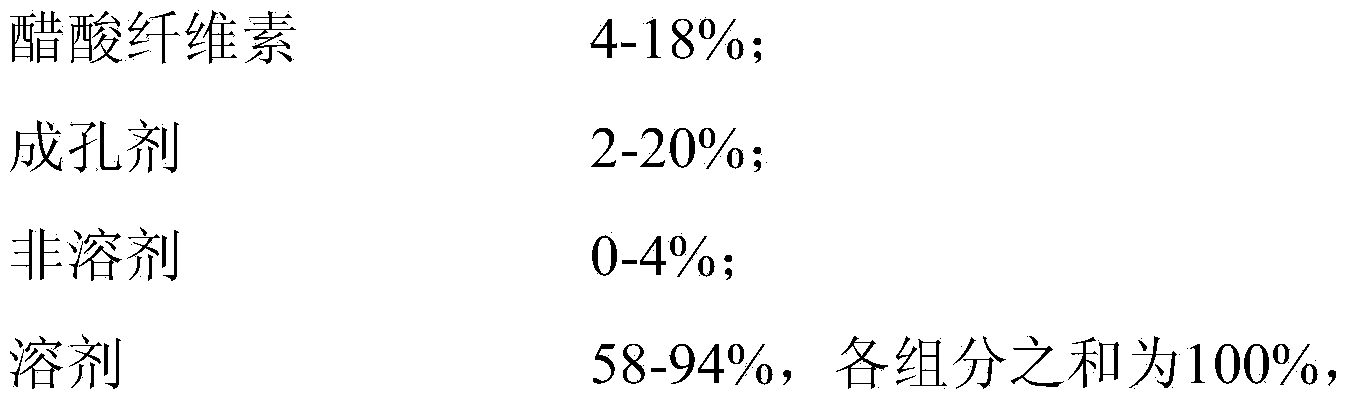

[0019] (2) Preparation of casting film: The casting film is obtained by mixing cellulose acetate, pore former and non-solvent in a solvent at 60-90°C, stirring for 3-5 hours and dissolving. The quality score is composed of:

[0020]

[0021] Wherein, the acetyl content of the cellulose acetate is 38-41.5% and the molecular weight is 30,000-50,000; the pore-forming agent...

Embodiment 1

[0027] (1) Using a 16-spindle two-dimensional braiding machine, weave the 450D / 90F diacetate filament into a hollow braided tube with a diameter of 1.5mm;

[0028] (2) Mix 8% of the total mass of the system with cellulose acetate (39.8% acetyl content and 30000 molecular weight), 5% of the total mass of the system polyethylene glycol 10000, and 2% of the total mass of the system with water. It is dissolved in N,N-dimethylacetamide which accounts for 85% of the total mass of the system and stirred at 70°C for 4 hours to obtain a cellulose acetate casting solution;

[0029] (3) Using godet roll traction coating technology, the cellulose acetate casting film obtained in step (2) is uniformly coated on the surface of the hollow braided tube obtained in step (1) through a co-extrusion spinneret at 60°C , At a traction speed of 40m / h, after passing through an air gap of 10cm, it is immersed in water at 20°C to solidify to form a homogeneous reinforced cellulose acetate hollow fiber membr...

Embodiment 2

[0032] (1) Using a 16-spindle two-dimensional braiding machine, weave the 450D / 90F diacetate filament into a hollow braided tube with a diameter of 1.5mm;

[0033] (2) Cellulose acetate (with an acetyl content of 38% and a molecular weight of 40,000) accounting for 9% of the total mass of the system, polyvinylpyrrolidone K15 accounting for 4% of the total mass of the system, and Tween-80 accounting for 2% of the total mass of the system Mix with dimethyl sulfoxide accounting for 85% of the total mass of the system, and stir at 70°C for 4 hours to dissolve to obtain a cellulose acetate casting solution;

[0034] (3) Using godet roller traction coating technology, the cellulose acetate casting film obtained in step (2) is uniformly coated on the surface of the hollow braided tube obtained in step (1) through a co-extrusion spinneret at 70°C At a traction speed of 60m / h, after passing through an air gap of 20cm, it is immersed in water at 25°C to solidify and form a homogeneous reinfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com