Modified urea resin low-temperature phase change microcapsule and preparation method thereof

A urea-formaldehyde resin, low-temperature phase change technology, applied in microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of urea-formaldehyde resin poor water resistance and weather resistance, large release of free formaldehyde, short storage period, etc. The effect of inhibiting food spoilage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The specifications of each used preparation raw material or reagent of the present invention and the information of the manufacturer are as follows:

[0050] Urea, analytically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0051] Formaldehyde, analytically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0052] Triethanolamine, analytically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0053] Melamine, analytically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0054] n-tetradecane, analytically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0055] Polyvinyl alcohol, analytically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0056] Tween-80, analytically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0057] Span-80, analytically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0058] Sodium chloride, analytically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0059] Sodium carbonate, analytically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0060] Hydrochloric acid, analy...

Embodiment 1

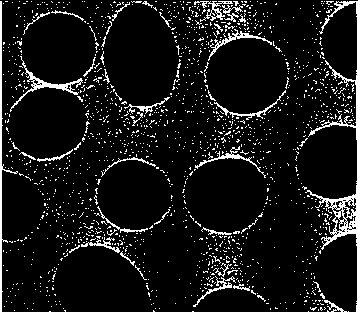

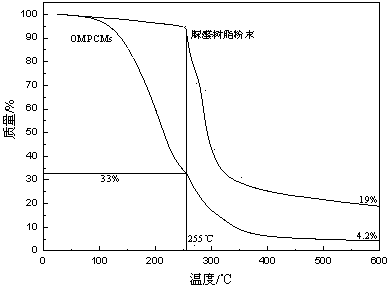

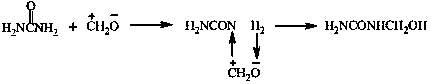

[0074] A low-temperature phase-change solid microcapsule of modified urea-formaldehyde resin, using the low-temperature organic phase-change material n-tetradecane as the core material, and wrapping urea and formaldehyde on the surface of the low-temperature organic phase-change material n-tetradecane by in-situ polymerization As the raw material, the urea-formaldehyde resin obtained through polycondensation reaction with melamine and polyvinyl alcohol as the modifier is used as the outer wall material.

[0075] The composition and content of the above-mentioned modified urea-formaldehyde resin low-temperature phase-change solid microcapsules are calculated in parts by weight as follows:

[0076] urea 5 parts

[0077] Formaldehyde 15 parts

[0078] 2.2 parts of melamine

[0079] Span-80 0.45 parts

[0080] Tween-80 0.55 parts

[0081] 20 parts n-tetradecane

[0082] 0.2 parts of polyvinyl alcohol

[0083] Mass percentage concentration is 10 parts of sodium chloride aqueo...

Embodiment 2

[0093] A low-temperature phase-change solid microcapsule of modified urea-formaldehyde resin, using the low-temperature organic phase-change material n-tetradecane as the core material, and wrapping urea and formaldehyde on the surface of the low-temperature organic phase-change material n-tetradecane by in-situ polymerization As the raw material, the urea-formaldehyde resin obtained through polycondensation reaction with melamine and polyvinyl alcohol as the modifier is used as the outer wall material.

[0094] The composition and content of the above-mentioned modified urea-formaldehyde resin low-temperature phase-change solid microcapsules are calculated in parts by weight as follows:

[0095] Urea 5.6 parts

[0096] Formaldehyde 18 parts

[0097] 2.5 parts of melamine

[0098] Span-80 0.48 parts

[0099] Tween-80 0.52 parts

[0100] n-tetradecane 25 parts

[0101] 0.3 parts of polyvinyl alcohol

[0102] Mass percent concentration is 12 parts of 10% sodium chloride aq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com