A two-stage dry digestion method and device for waste

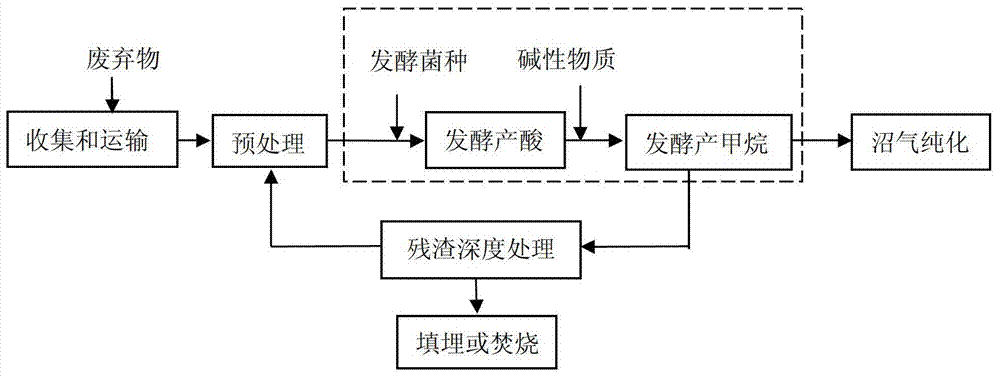

A technology of waste and dry process, applied in the direction of biochemical cleaning equipment, biochemical equipment and methods, chemical instruments and methods, etc., to achieve high methane yield, release inhibition, improve waste conversion rate and methane yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

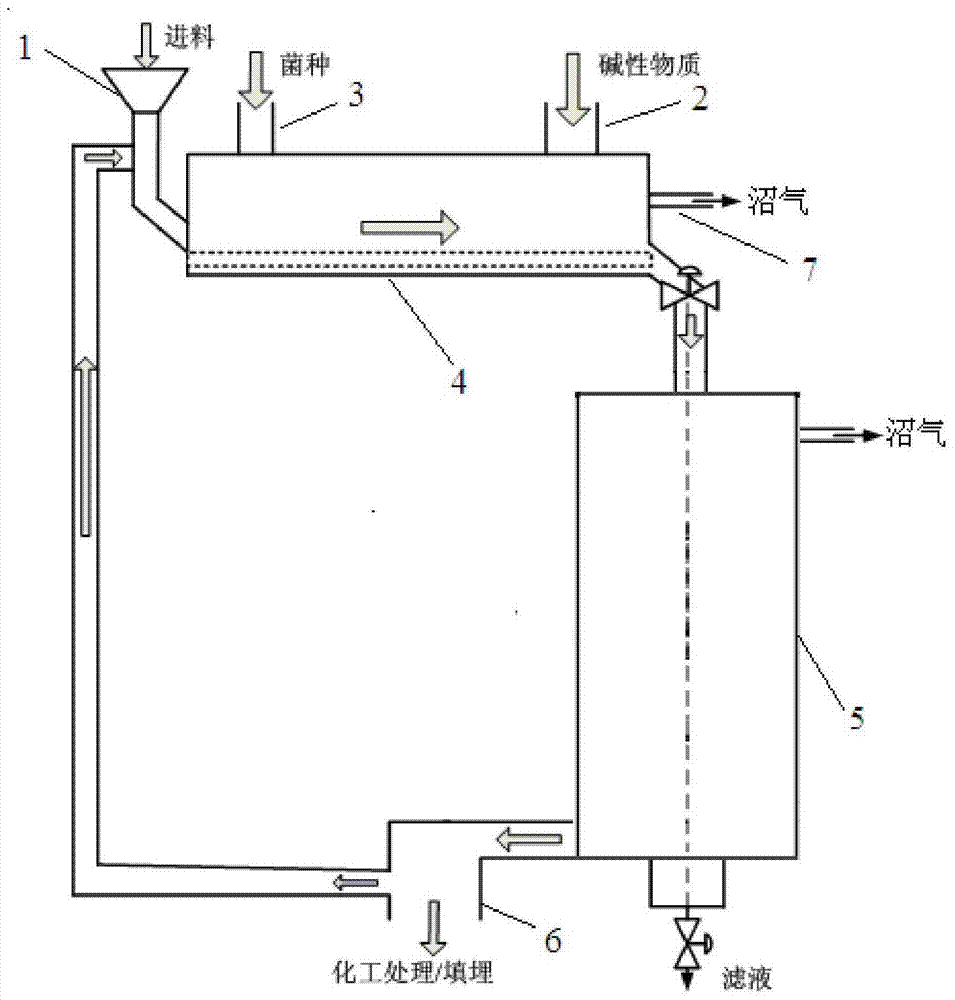

[0052] Example 1: Two-stage dry digestion of municipal solid waste

[0053] The two-stage anaerobic digestion reaction device adopted in this embodiment (such as figure 2 (shown) includes a rotary kiln 4 and a second-stage reactor 5 in sequence according to the material flow direction; the front end of the rotary kiln 4 is provided with a feed port 1 and a strain inlet 3 in sequence according to the material flow direction, and an alkali Reactive substance inlet 2 and rotary kiln biogas outlet 7; the furnace body of the rotary kiln 4 is fixed, and an inner shaft is arranged inside, which can drive the blades on the inner shaft to rotate; the upper part of the second-stage reactor 5 is provided with a second-stage reaction There is a biogas outlet of the device, and a methanation reaction product outlet 6 is provided at the lower part, and the methanation reaction product outlet 6 is connected to the feed port 1 .

[0054] First, classify the collected municipal solid waste, r...

Embodiment 2

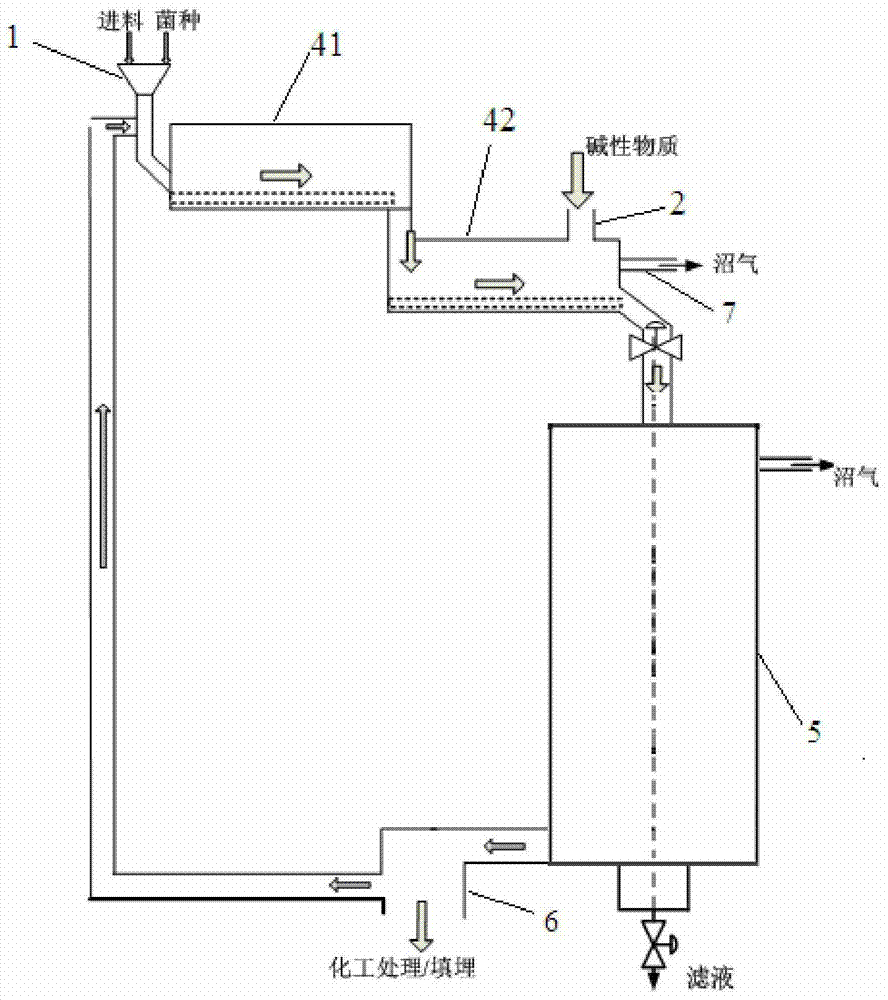

[0055] Example 2: Municipal solid waste mixed with kitchen waste and two-stage dry digestion

[0056] The two-stage anaerobic digestion reaction device used in this embodiment uses two series-connected rotary kilns as the first stage dry digestion reactor (such as image 3 As shown), it includes a rotary kiln 4 and a second-stage reactor 5 in sequence according to the material flow direction; the rotary kiln 4 is divided into a first rotary kiln 41 and a second rotary kiln 42 in sequence, and the front end of the first rotary kiln 41 is provided with There is a feed port 1, the front end of the second rotary kiln 42 is provided with an alkaline substance inlet 2, and the rear end is provided with a rotary kiln biogas outlet 7; the furnace body of the first rotary kiln 41 rotates, and the furnace body of the second rotary kiln 42 Fixed, with an inner shaft inside, which drives the blades on the inner shaft to rotate; the upper part of the second-stage reactor 5 is provided with...

Embodiment 3

[0058] Example 3: Two-stage dry digestion of municipal solid waste mixed with industrial waste

[0059] The device used in this example is substantially the same as that in Example 2, with two series-connected rotary kilns as the first stage of dry digestion reactor, the difference is that the front of the first rotary kiln is provided with a strain inlet, which is located at the feed after the mouth.

[0060] Mix the screened municipal solid waste with distiller's grains in a mixing ratio of 1:1, and send 2000 kg of the mixture into the first rotary kiln 41 through the feed port 1; Concentrate, enter 1000L of microbial catalyst with a concentration of 10g / L into the first rotary kiln 41 through the strain inlet, and mix and ferment with the mixed waste through the baffle. The fermentation temperature is 37°C, the fermentation time is 10 days, and the fermentation pressure is: Under normal pressure, after detection and analysis, the fermentation output of organic acid is 0.07...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com