Regenerated cellulose fiber containing microencapsulated anti-mite drug and preparation method thereof

A technology of regenerated cellulose and microencapsulation, applied in the field of textile production, to achieve the effect of cool and fragrant smell and good persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

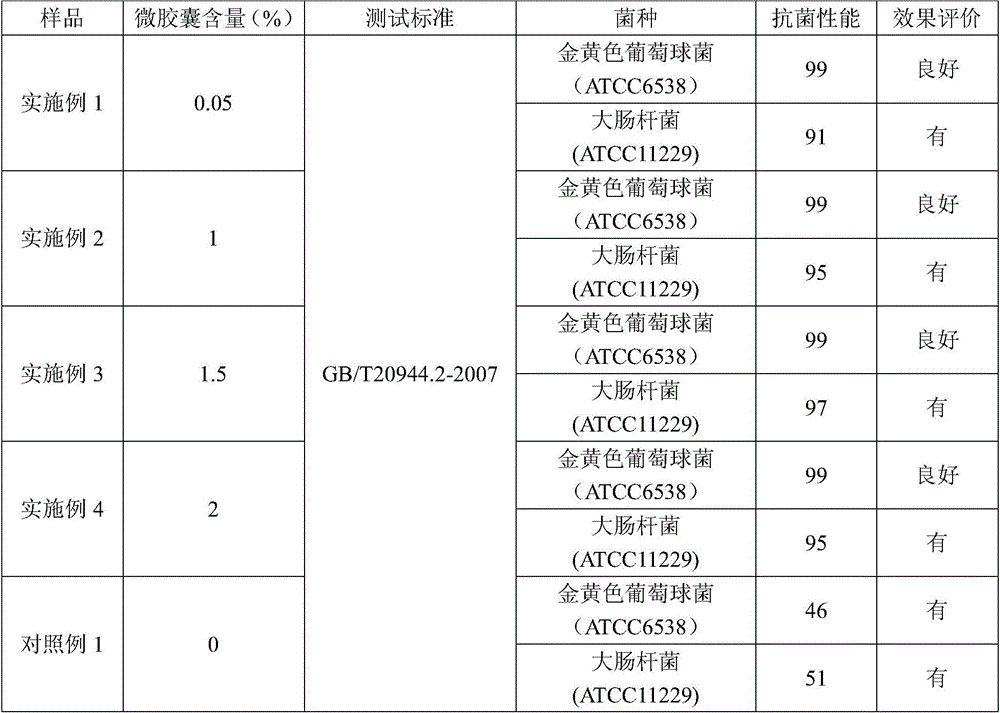

Embodiment 1

[0026] The 99% purity borneol extract from the natural plant dipterocarp was dissolved in wormwood essential oil to prepare borneol-wormwood essential oil with a mass concentration of borneol of 5%.

[0027] In parts by weight, get 2 parts of toluene diisocyanate and 4 parts of borneol-wormwood essential oil solution and mix uniformly to form an oil phase, put this oil phase into 10 parts of water containing wt1% emulsifier polyvinyl alcohol (Mw1500), and use high-speed emulsification Machine emulsification, rotating speed 9200-9600r / min, emulsification 5min, get oil-in-water emulsion. To make the emulsion stable, add 10 parts of aqueous solution containing wt0.13% dispersant sodium alginate, add 4.6 parts of polyethylene glycol (Mw400-600) and 1% catalyst dibutyltin dilaurate at the same time, stir at room temperature for 2 hour, then the temperature was raised to 70°C, the chain extender ethylenediamine was added, and the stirring was continued for 1 hour to cure the wall ma...

Embodiment 2

[0032] The synthetic borneol with a purity of 98% was dissolved in wormwood essential oil to prepare borneol-wormwood essential oil with a mass concentration of borneol of 10%.

[0033] In parts by weight, get 5 parts of toluene diisocyanate and 5 parts of borneol-wormwood essential oil solution and mix uniformly to form an oil phase, put this oil phase into 12 parts of water containing wt1.2% emulsifier polyvinyl alcohol (Mw1500), use Emulsify with a high-speed emulsifier at a speed of 9200-9600r / min for 5 minutes to obtain an oil-in-water emulsion. To make the emulsion stable, add 10 parts of aqueous solution containing wt0.15% dispersant sodium alginate, add 5.4 parts of polyethylene glycol (Mw400-600) and 1% catalyst dibutyltin dilaurate at the same time, stir at room temperature for 2 hour, then the temperature was raised to 70°C, the chain extender ethylenediamine was added, and the stirring was continued for 1 hour to cure the wall material. The obtained slurry is wash...

Embodiment 3

[0038] The 99% purity borneol extract from the natural plant dipterocarp was dissolved in wormwood essential oil to prepare borneol-wormwood essential oil with a mass concentration of borneol of 5%.

[0039] In parts by weight, get 2 parts of toluene diisocyanate and 4 parts of borneol-wormwood essential oil solution and mix uniformly to form an oil phase, put this oil phase into 10 parts of water containing wt1% emulsifier polyvinyl alcohol (Mw1500), and use high-speed emulsification Machine emulsification, rotating speed 9200-9600r / min, emulsification 5min, get oil-in-water emulsion. To make the emulsion stable, add 10 parts of aqueous solution containing wt0.13% dispersant sodium alginate, add 4.6 parts of polyethylene glycol (Mw400-600) and 1% catalyst dibutyltin dilaurate at the same time, stir at room temperature for 2 hour, then the temperature was raised to 70°C, the chain extender ethylenediamine was added, and the stirring was continued for 1 hour to cure the wall ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com