Preparation method of antibacterial and anti-mite cotton fiber and product of antibacterial and anti-mite cotton fiber

An anti-mite cotton and cotton fiber technology, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of weak binding force and easy falling off, and achieve the effect of strong anti-mite effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

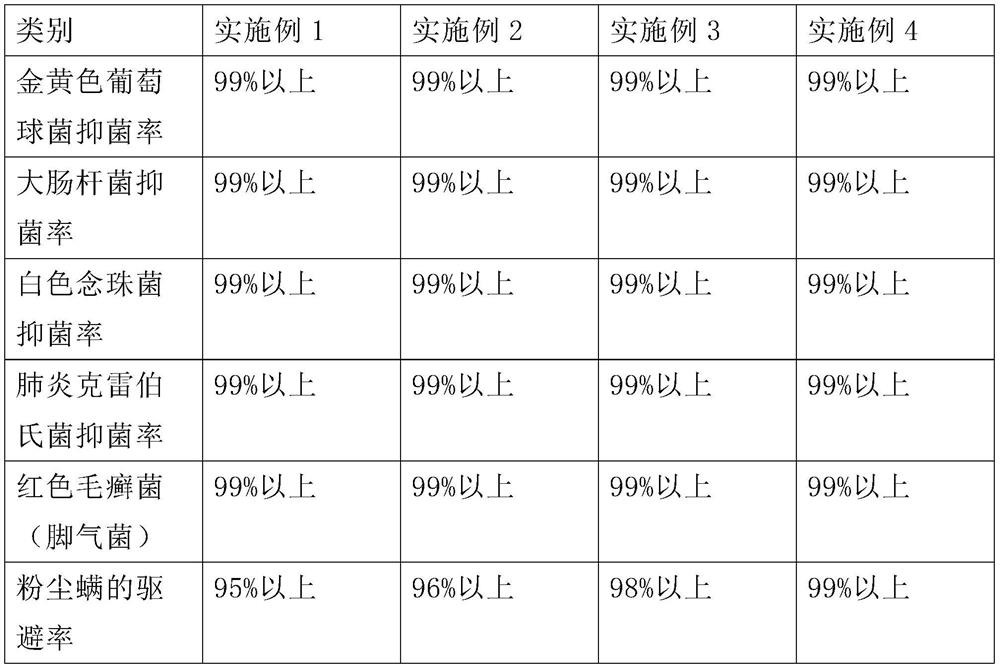

Examples

Embodiment 1

[0036] A preparation method of antibacterial and anti-mite cotton fiber, comprising the steps of:

[0037] first step:

[0038] The cotton fiber is subjected to surface oil and fruit wax removal treatment in clean water at a temperature of 90°C for 60 minutes and then washed;

[0039] Step two:

[0040] Completely soak the absorbent cotton product obtained in the first step into an aqueous solution with a mass fraction of 2% trimethoxysilane, heat it in a water bath at a temperature of 60° C. to obtain a cotton fiber suspension and keep it warm for 2 hours after fully stirring for 30 minutes;

[0041] third step:

[0042] The cotton fiber suspension is added to a mixed solution with a concentration of 5% dimethyl octadecyl ammonium chloride and a concentration of 8% propylene glycol and stirred; when heated to 80°C, an appropriate amount of 5% by mass fraction The citric acid was incubated for 3 hours, then dried at a constant temperature of 80°C for 60 minutes and cooled t...

Embodiment 2

[0049] A preparation method of antibacterial and anti-mite cotton fiber, comprising the steps of:

[0050] first step:

[0051] The cotton fiber is subjected to surface oil and fruit wax removal treatment at a temperature of 100°C in clean water for 45 minutes and then washed;

[0052] Step two:

[0053] Completely soak the absorbent cotton product obtained in the first step into an aqueous solution with a mass fraction of 1% trimethoxysilane, heat it in a water bath at a temperature of 80° C. to obtain a cotton fiber suspension and keep it warm for 1 hour after fully stirring for 15 minutes;

[0054] third step:

[0055] Add the cotton fiber suspension into a mixed solution with a concentration of 3% dimethyl octadecyl ammonium chloride and a concentration of 5% propylene glycol and stir; when heated to 100°C, add an appropriate amount of 3% by mass fraction The citric acid was incubated for 2 hours, then dried at a constant temperature of 100°C for 30 minutes and cooled t...

Embodiment 3

[0062] A preparation method of antibacterial and anti-mite cotton fiber, comprising the steps of:

[0063] first step:

[0064] At a temperature of 90°C, the cotton fiber is subjected to surface oil and fruit wax removal treatment in a 2% sodium hydroxide aqueous solution with a mass fraction of 30 minutes and then washed;

[0065] Step two:

[0066] Completely soak the absorbent cotton product obtained in the first step into an aqueous solution with a mass fraction of 1.5% trimethoxysilane, heat it in a water bath at a temperature of 65° C. to obtain a cotton fiber suspension after 20 minutes of sufficient stirring, and keep it warm for 1.5 hours;

[0067] third step:

[0068]Add the cotton fiber suspension into a mixed solution with a concentration of 2% dimethyl octadecyl ammonium chloride and a concentration of 3% propylene glycol and stir; when heated to 90°C, add an appropriate amount of 1.5% by mass fraction The citric acid was incubated for 1.5 hours, then dried at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com