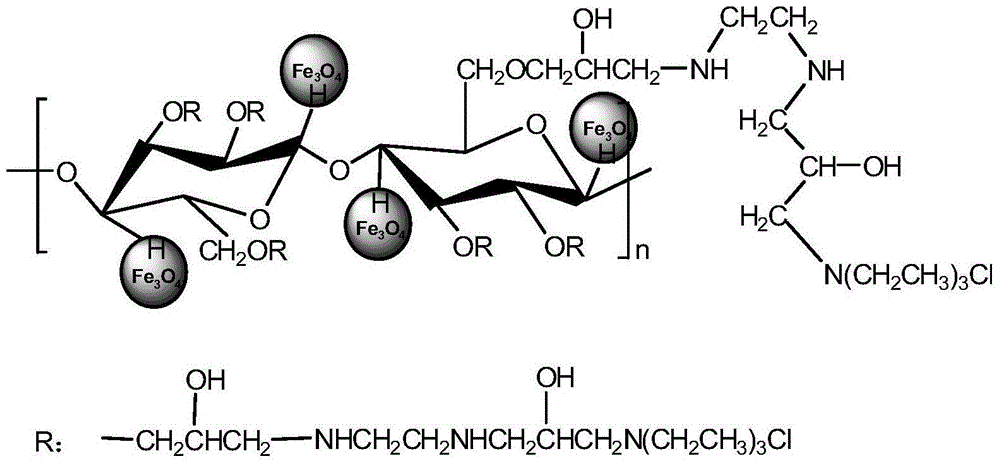

Preparation and application of modified magnetic straw anion adsorbent

An adsorbent and anion technology, which is applied in the field of preparing modified magnetic straw anion adsorbents, to achieve the effects of increased reactive sites, improved mechanical strength and wear resistance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

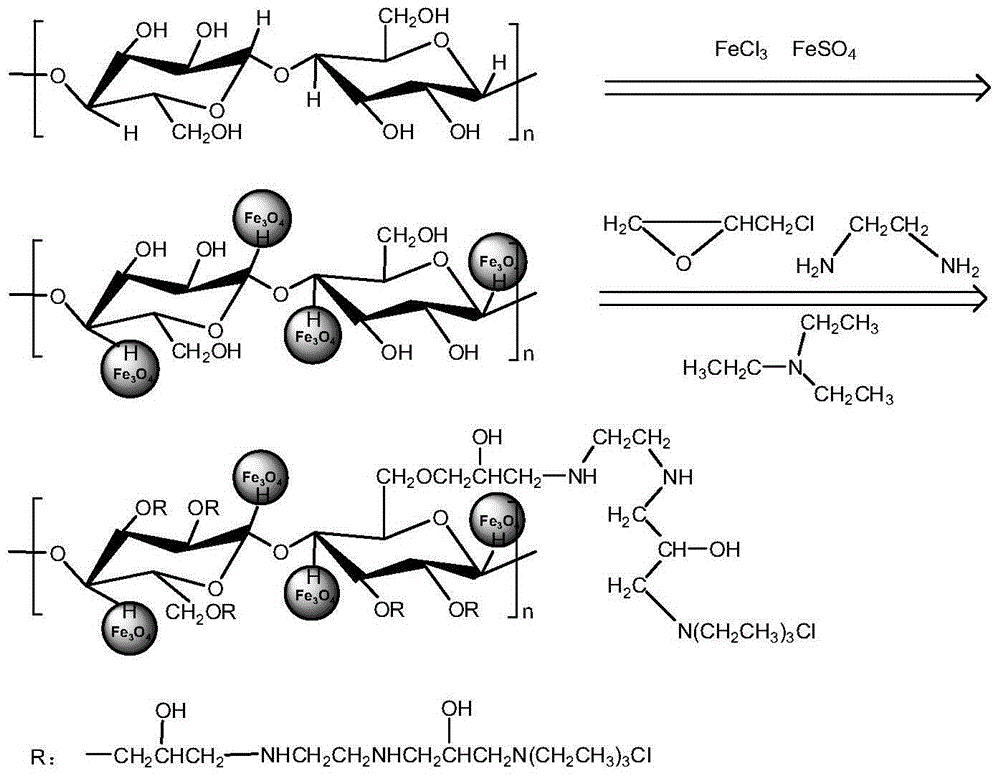

Method used

Image

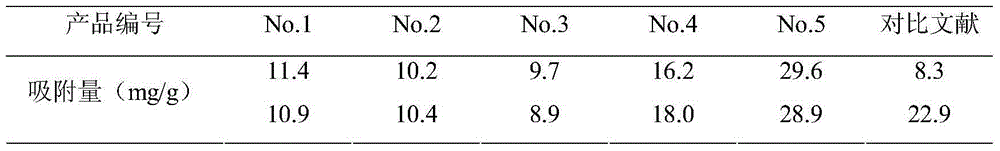

Examples

Embodiment 1

[0034] A preparation method of a modified magnetic straw anion adsorbent, comprising the following steps:

[0035](1) Take 3g of corn stalks and dry, pulverize, and sieve to make corn stalk particles with a particle size of 500 μm, and mix them with 300ml of Fe 2+ / Fe 3+ The mixed liquid is mixed, the concentration of iron element is 0.2mol / L, Fe 2+ / Fe 3+ Fe in the mixture 2+ : Fe 3+ Molar ratio of 1:2; then add 25mL of 25% ammonia water under stirring condition, stir and react at 70°C for 4 hours, the whole reaction process is carried out in an anaerobic environment, cool down after the reaction, and use a magnet to precipitate the product , and then washed with deionized water, suction filtered, vacuum-dried at 104°C, and passed through a 20-mesh sieve to remove ferric oxide impurities to obtain a magnetic straw adsorbent;

[0036] (2) Mix the magnetic straw adsorbent prepared in step (1) with 20ml epichlorohydrin in a 250mL three-necked flask, stir and add 20ml of N,N...

Embodiment 2

[0040] A preparation method of a modified magnetic straw anion adsorbent, comprising the following steps:

[0041] (1) Take 3g of corn stalks and dry, pulverize, and sieve to make corn stalk particles with a particle size of 400 μm, and mix them with 270ml of Fe 2+ / Fe 3+ The mixed solution is mixed, the concentration of iron element is 0.1mol / L, Fe 2+ / Fe 3+ Fe in the mixture 2+ : Fe 3+ Molar ratio=1:2.5; then add 30mL of 25% ammonia water under stirring condition, stir and react at 80°C for 2.5 hours, the whole reaction process is carried out under anaerobic environment, cool down after the reaction, and use a magnet to separate out the product , and then washed with deionized water, suction filtered, vacuum-dried at 104°C, and passed through a 25-mesh sieve to remove ferric oxide impurities to obtain a magnetic straw adsorbent;

[0042] (2) Mix the magnetic straw adsorbent prepared in step (1) with 12ml of epichlorohydrin in a 250mL three-necked flask, stir and add 12m...

Embodiment 3

[0046] The preparation method of the modified magnetic stalk anion adsorbent as described in Example 1, the difference is:

[0047] (1) Take 3g of corn stalks and dry, pulverize, and sieve to make corn stalk particles with a particle size of 450 μm, and mix them with 400ml of Fe 2+ / Fe 3+ The mixed liquid is mixed, the concentration of iron element is 0.3mol / L, Fe 2+ / Fe 3+ Fe in the mixture 2+ : Fe 3+ Molar ratio=1:3; add 45mL of 25% ammonia water, stir and react at 60°C for 6 hours,

[0048] (2) The addition amount of epichlorohydrin and reaction medium N,N-dimethylformamide (DMF) is 30ml and 5ml respectively, and the reaction is stirred and reacted at 60°C for 60min;

[0049] (3) The amount of cross-linking agent ethylenediamine added is 9 mL, the temperature is controlled at 90°C and the reaction is stirred for 50 minutes. After the reaction is completed, the product is washed with deionized water, filtered with suction, vacuum-dried at 103°C, and passed through a 30-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com