Dispersing agent for grinding triple superphosphate with branched structure and preparation method thereof

A branched structure, dispersant technology, applied in chemical instruments and methods, chemical/physical processes, transportation and packaging, etc., can solve the problems of reduced dispersant utilization efficiency and precipitation, and achieve excellent dispersion performance and simple operation. Ease of operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

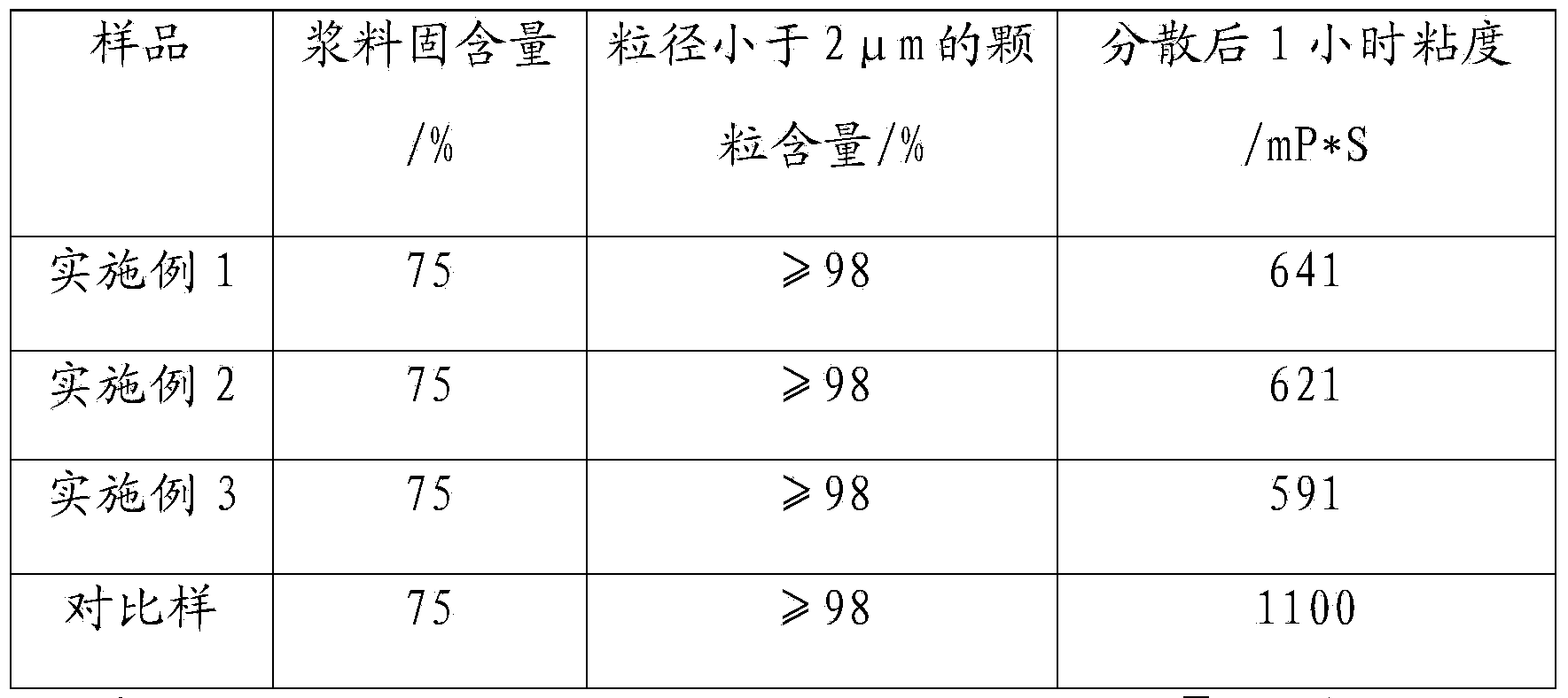

Examples

Embodiment 1

[0024] Preparation of branched structure sodium polyacrylate:

[0025] In the quartz reaction vessel, add 10.81 g of p-vinylbenzyl dithiobenzoate containing double bond chain transfer agent, 5.60 g of photoinitiator 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, Solvent tetrahydrofuran 474.0g and monomer acrylic acid 144.05g. The system was bubbled with nitrogen for 20 minutes and then sealed. During the bubbling process, avoid light. The reactor should be wrapped with aluminum foil, and then placed under an ultraviolet lamp with a central wavelength of 365nm. The ultraviolet light is irradiated by a cut-off plate with a cut-off wavelength greater than 254nm, while maintaining the incident intensity of ultraviolet light at 10mw / cm 2 , Remove the aluminum foil at room temperature and start to react for 8 hours. Add a small amount of water to dilute after distilling off solvent after finishing, and gained solution is 4.36 with 65.23g sodium hydroxide solution (32%) regulation...

Embodiment 2

[0027] The preparation of the polysodium methacrylate of branched structure:

[0028] Add 10.72g of S-p-vinylphenyl S'-propyl trithiocarbonate containing double bond chain transfer agent, 2.91g of photoinitiator benzophenone, 453.01g of solvent tetrahydrofuran and monomer A into the quartz reaction vessel. Acrylic acid 168.00g. The system was bubbled with nitrogen for 20 minutes and then sealed. During the bubbling process, avoid light. The reactor should be wrapped with aluminum foil, and then placed under an ultraviolet lamp with a central wavelength of 365nm. The ultraviolet light is irradiated by a cut-off plate with a cut-off wavelength greater than 254nm, while maintaining the incident intensity of ultraviolet light at 12mw / cm 2 , Remove the aluminum foil at room temperature and start to react for 6 hours. After the end, the gained solution was distilled to remove the solvent, added a small amount of water to dilute, then added 73.08g sodium hydroxide solution (32%) in...

Embodiment 3

[0030] Preparation of branched structure poly(sodium acrylate-co-sodium methacrylate):

[0031] Add 10.89 g of double bond-containing chain transfer agent S-p-vinylphenyl S'-propyl trithiocarbonate, photoinitiator 2,4,6-trimethylbenzoyl-diphenyl Phosphine oxide 7.01g, solvent tetrahydrofuran 454.79g and monomer methacrylic acid 83.85g and acrylic acid 72.13g. The system was bubbled with nitrogen for 20 minutes and then sealed. During the bubbling process, avoid light. The reactor should be wrapped with aluminum foil, and then placed under an ultraviolet lamp with a central wavelength of 365nm. The ultraviolet light is irradiated by a cut-off plate with a cut-off wavelength greater than 254nm, while maintaining the incident intensity of ultraviolet light at 12mw / cm 2 , Remove the aluminum foil at room temperature and start to react for 8 hours. After the solvent is distilled off after the end, add a small amount of water to dilute, then add 64.94g sodium hydroxide solution (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com