Ultra-high molecular weight polyethylene composite tube

A polyethylene composite pipe, ultra-high molecular weight technology, applied in the field of polymer materials, can solve the problems of high viscosity and difficulty in extrusion processing of pipes, achieve low temperature resistance, increase Vicat softening temperature and mechanical strength, and high extrusion The effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

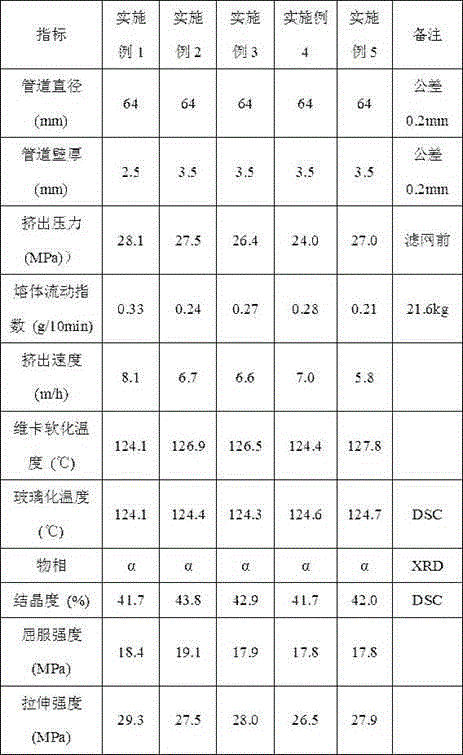

Examples

Embodiment 1

[0042]Take 100 parts of ultra-high molecular weight polyethylene with a viscosity-average molecular weight of 3.8 million, dry it at 120°C for 10 hours before use, and then cool it to room temperature naturally. Take another 0.5 part of mullite, 0.5 part of corundum, and 1 part of polyethylene wax with a molecular weight of 5000. , 0.5 parts of calcium stearate, 0.1 parts of fumed silica, 0.3 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid, 0.1 parts of pentaerythritol ester and 0.1 parts of triphosphite (2,4-Di-tert-butylphenyl) ester is placed in a high-speed stirrer, stirred at room temperature for 5 minutes at high speed, and the material in the high-speed stirrer is heated to 40°C under low-speed stirring, and then passed through the observation hole of the high-speed stirrer Spray the cross-linking agent evenly under the conditions of low-speed stirring and constant temperature of 40°C, wherein the cross-linking agent is a mixed solution of 1 part ...

Embodiment 2

[0044] Take 100 parts of ultra-high molecular weight polyethylene with a viscosity average molecular weight of 6 million, dry it at 120°C for 10 hours before use, and then cool it to room temperature naturally. Take another 15 parts of mullite, 15 parts of corundum, and 10 parts of high-density polyethylene with a molecular weight of 100,000. Polyethylene, 3 parts of zinc stearate, 0.5 parts of fumed silica, 1.5 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid, 1 part of pentaerythritol ester and 1 part of Tris(2,4-di-tert-butylphenyl) phosphate is placed in a high-speed stirrer, stirred at room temperature for 8 minutes at high speed, and the material in the high-speed stirrer is heated to 90°C under low-speed stirring, and then passed through the high-speed stirrer. The observation hole is uniformly sprayed with a cross-linking agent under low-speed stirring and a constant temperature of 90°C. The cross-linking agent is a mixture of 5 parts of silane, 0.3...

Embodiment 3

[0046] Take 100 parts of ultra-high molecular weight polyethylene with a viscosity average molecular weight of 5 million, dry it at 120°C for 10 hours before use, and then cool it to room temperature naturally. Take another 10 parts of mullite, 5 parts of corundum, and 5 parts of high-density polyethylene with a molecular weight of 300,000. Polyethylene, 2 parts of zinc stearate, 0.5 parts of fumed silica, 1 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid, 0.5 parts of pentaerythritol ester and 0.5 parts of Tris(2,4-di-tert-butylphenyl) phosphate is placed in a high-speed stirrer, stirred at room temperature for 6 minutes at high speed, and the material in the high-speed stirrer is heated to 70°C under low-speed stirring, and then passed through the high-speed stirrer. The observation hole is evenly sprayed with a cross-linking agent under low-speed stirring and a constant temperature of 70°C. The cross-linking agent is a mixture of 3 parts of silane, 0.15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com