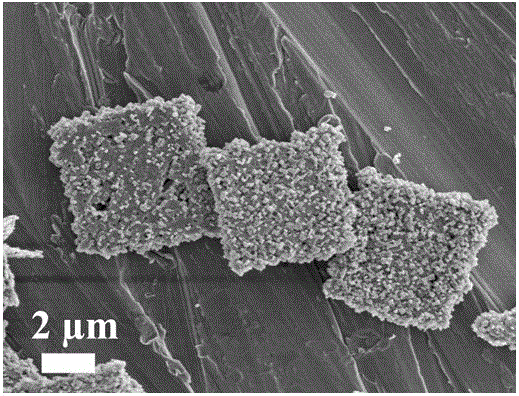

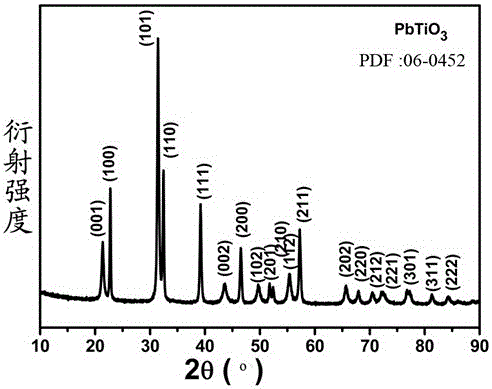

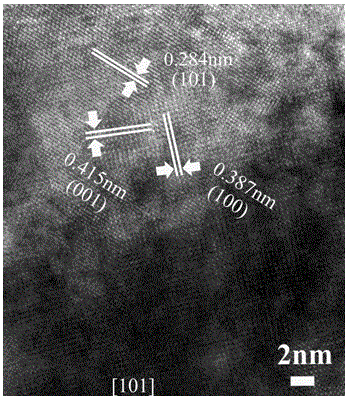

A nanoparticle self-assembled tetragonal perovskite phase Pbtio 3 Preparation method of microsheets

A perovskite phase and nanoparticle technology, applied in chemical instruments and methods, solutions from room temperature liquid solvents, single crystal growth, etc., can solve the problems of low orientation and no discovery, and achieve good crystallinity and regular morphology. , the effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) The TiO 2 The powder was dissolved in an aqueous solution with a concentration of 15mol / L KOH to adjust the Ti 4+ The concentration is 0.5mol / L, and TiO is obtained 2 alkaline aqueous solution;

[0019] 2) Under stirring, add the TiO prepared in step 1) to the 2 Pb(NO) was added to the alkaline solution 3 ) 2 Powder, regulated Pb 2+ The ion concentration is 0.5mol / L, after stirring for 5min, add anhydrous ethanol solution to the system, the volume of the added anhydrous ethanol is twice the volume of the KOH aqueous solution used in step 1), and continue stirring for 2h to obtain titanium and Lead hydroxide suspension;

[0020] 3) Add the hydroxide suspension of titanium and lead prepared in step 2) into the inner tank of a 50ml polytetrafluoroethylene reactor, and adjust the volume of the reaction material in the inner tank of the reactor with absolute ethanol Reach 80% of the volume of the inner tank of the reactor to obtain the reaction material;

[0021] ...

Embodiment 2

[0023] 1) The TiO 2 The powder was dissolved in an aqueous solution with a concentration of 15mol / L KOH to adjust the Ti 4+ The concentration is 0.5mol / L, and TiO is obtained 2 alkaline aqueous solution;

[0024] 2) Under stirring, add the TiO prepared in step 1) to the 2 Pb(NO) was added to the alkaline solution 3 ) 2 Powder, regulated Pb 2+ The ion concentration is 0.625mol / L, after stirring for 5min, add anhydrous ethanol solution to the system, the volume of the added anhydrous ethanol is 3 times the volume of the KOH aqueous solution used in step 1), and continue stirring for 3h to obtain titanium and Lead hydroxide suspension;

[0025] 3) Add the hydroxide suspension of titanium and lead prepared in step 2) into the inner tank of a 50ml polytetrafluoroethylene reactor, and adjust the volume of the reaction material in the inner tank of the reactor with absolute ethanol Reach 80% of the volume of the inner tank of the reactor to obtain the reaction material;

[00...

Embodiment 3

[0028] 1) The TiO 2 The powder was dissolved in an aqueous solution with a concentration of 15mol / L KOH to adjust the Ti 4+ The concentration is 0.5mol / L, and TiO is obtained 2 alkaline aqueous solution;

[0029] 2) Under stirring, add the TiO prepared in step 1) to the 2 Pb(NO) was added to the alkaline solution 3 ) 2 Powder, regulated Pb 2+ The ion concentration is 0.6 mol / L. After stirring for 5 min, anhydrous ethanol solution is added to the system. The volume of the added anhydrous ethanol is twice the volume of the KOH aqueous solution used in step 1), and stirring is continued for 3 h to obtain titanium and Lead hydroxide suspension;

[0030] 3) Add the hydroxide suspension of titanium and lead prepared in step 2) into the inner tank of a 50ml polytetrafluoroethylene reactor, and adjust the volume of the reaction material in the inner tank of the reactor with absolute ethanol Reach 80% of the volume of the inner tank of the reactor to obtain the reaction material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com