Cathode preparation process for reducing niobium oxide capacitor equivalent series resistance

A technology of equivalent series resistance and preparation process, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of unfavorable mass production of niobium oxide capacitors, low filling rate of anode pellets, and low production efficiency, and achieve equivalent series resistance. The effect of resistance reduction, elimination of interlayer contact resistance, and improvement of filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

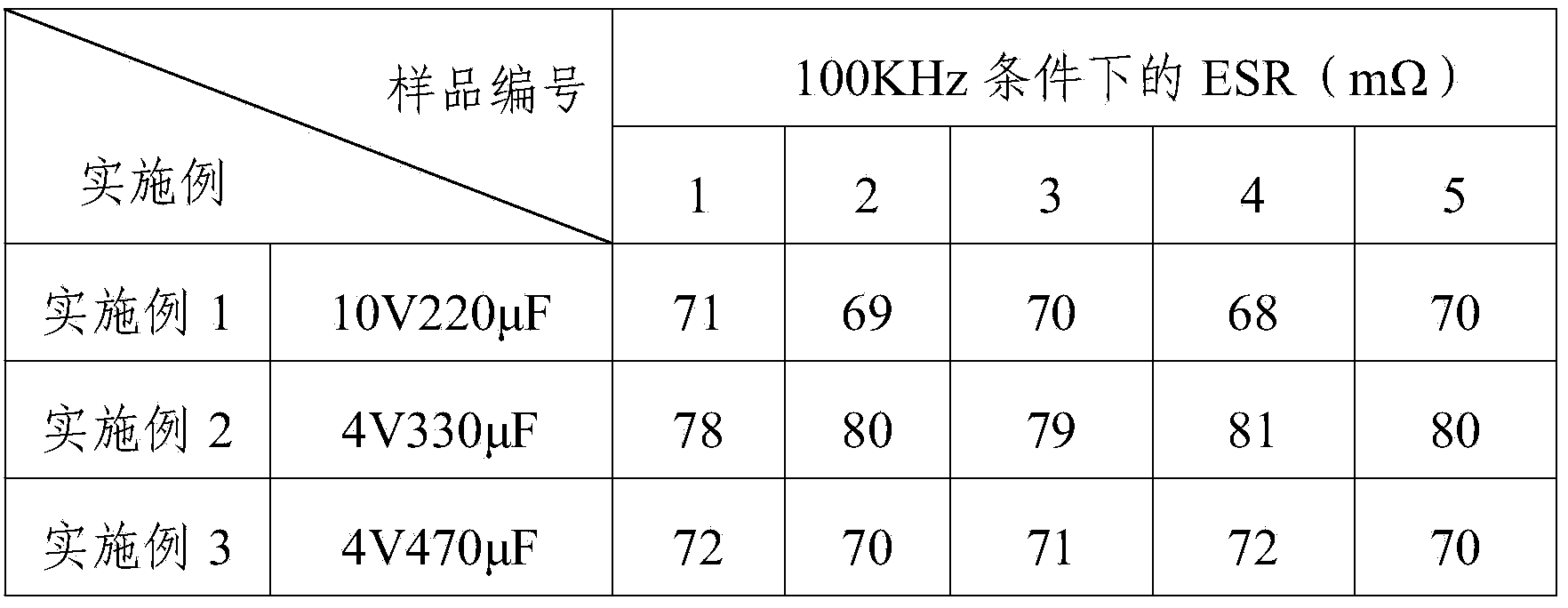

Embodiment 1

[0042] Select niobium monoxide powder with a CV value of 80000μF·V / g, use tantalum wire with a diameter of Ф0.29 as the anode lead wire, press a niobium oxide capacitor anode pellet with a specification of 10V220μF, and heat it under high temperature at 1500℃ / 20min The porous anode body is sintered in vacuum, and the sintered anode body is anodically formed in a phosphoric acid aqueous solution at 40V to manufacture a dielectric layer, and then a cathode layer is prepared on the surface of the anode body according to the following process.

[0043] (1) Processing of cathode semiconductor:

[0044] a. Immerse the anode pellets in a low-concentration manganese nitrate solution: the specific gravity is 1.05g / cm3; the immersion temperature is 50°C, and the immersion time is 7min; the thermal decomposition temperature is 250°C, and the decomposition time is 5min; the dehydration temperature is 85°C, and the dehydration time 20min; thermally decompose in saturated water vapor; repea...

Embodiment 2

[0062] Select niobium monoxide powder with a CV value of 80000μF·V / g, use tantalum wire with a diameter of Ф0.29 as the anode lead wire, press a niobium oxide capacitor anode pellet with a specification of 4V330μF, and heat it at 1500°C / 20min The porous anode body is sintered in vacuum, and the sintered anode body is anodically formed in a phosphoric acid aqueous solution at 16V to manufacture a dielectric layer, and then a cathode layer is prepared on the surface of the anode body according to the following process.

[0063] (1) Processing of cathode semiconductor:

[0064] a. Immerse the anode pellets in a low-concentration manganese nitrate solution: the specific gravity is 1.10g / cm3; the immersion temperature is 45°C, and the immersion time is 7 minutes; the thermal decomposition temperature is 230°C, and the decomposition time is 10 minutes; the dehydration temperature is 120°C, and the dehydration time is 10 minutes. 10min; thermally decompose in saturated water vapor; r...

Embodiment 3

[0081] Select niobium monoxide powder with a CV value of 80000μF·V / g, use tantalum wire with a diameter of Ф0.29 as the anode lead wire, press a niobium oxide capacitor anode pellet with a specification of 4V470μF, and heat it under high temperature at 1500℃ / 20min The porous anode body is sintered in vacuum, and the sintered anode body is anodically formed in a phosphoric acid aqueous solution at 16V to manufacture a dielectric layer, and then a cathode layer is prepared on the surface of the anode body according to the following process.

[0082] (1) Processing of cathode semiconductor:

[0083] a. Immerse the anode pellets in low-concentration manganese nitrate solution: the specific gravity is 1.05g / cm3; the immersion temperature is 48°C, and the immersion time is 6min; the thermal decomposition temperature is 280°C, and the decomposition time is 5min; the dehydration temperature is 150°C, and the dehydration time 5min; thermally decompose in saturated water vapor; repeat 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com