Cerium-copper binary composite oxide catalyst and preparation method thereof

A binary composite and oxide technology, applied in the field of catalysis, can solve the problems of anti-sintering to be improved, and achieve the effects of low price, high content of active components and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

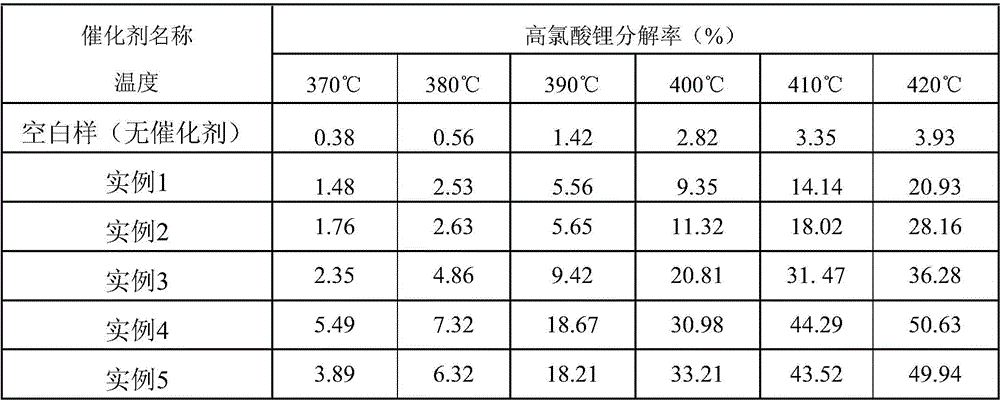

[0025] The preparation method of cerium-copper binary composite oxide catalyst, concrete steps are as follows:

[0026] (1) Determine the general formula Ce of the cerium-copper binary composite oxide catalyst x Cu 1-x o 1+x The value of x in the middle, and the value range of x is 0.2~0.8, then weigh Ce(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 0, add deionized water to dissolve and obtain metal ion solution;

[0027] (2) According to the molar ratio Ce x Cu 1-x o 1+x :C 6 h 8 o 7 ·H 2 O: C 2 h 6 o 2 For the ratio of 5:10:1, weigh citric acid monohydrate C 6 h 8 o 7 ·H 2 O and glycol C 2 h 6 o 2 Add to the metal ion solution that step (1) makes, and stir and dissolve to obtain the solution, Ce in the solution x Cu 1-x o 1+x The molar concentration range of 0.05~0.2mol / L, the molar concentration range of citric acid monohydrate is 0.1~0.4mol / L, the concentration range of ethylene glycol is 0.01~0.04mol / L, and then the obtained solution is in the range o...

Embodiment 1

[0032] Weigh an appropriate amount of Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water, and then according to the molar ratio Ce(NO 3 ) 3 ·6H 2 O: C 6 h 8 o 7 ·H 2 O: C 2 h 6 o 2 Add citric acid monohydrate C to the solution in a ratio of 5:10:1 6 h 8 o 7 ·H 2O and glycol C 2 h 6 o 2 , in the resulting solution Ce(NO 3 ) 3 ·6H 2 The molar concentration of O is 0.05mol / L, the molar concentration of citric acid is 0.1mol / L, and the molar concentration of ethylene glycol is 0.01mol / L. Heat and stir in a water bath at 70°C until evaporated, dry at 110°C for 12 hours, grind the mixture into a fine powder of about 200 mesh, heat to 300°C at a heating rate of 5°C / min, and pre-calcine in an air atmosphere After 1 hour, the furnace was cooled to room temperature; then the temperature was raised to 900° C. at a rate of 5° C. / min, calcined for 3 hours, and the furnace was cooled to room temperature to prepare a metal oxide catalyst.

Embodiment 2

[0034] Weigh an appropriate amount of Cu(NO 3 ) 2 ·3H 2 O was dissolved in deionized water, and then according to the molar ratio Cu(NO 3 ) 2 ·3H 2 O: C 6 h 8 o 7 ·H 2 O: C 2 h 6 o 2 Add citric acid monohydrate C to the solution in a ratio of 5:10:1 6 h 8 o 7 ·H 2 O and glycol C 2 h 6 o 2 , Cu(NO 3 ) 2 ·3H 2 The molar concentration of O is 0.05mol / L, the molar concentration of citric acid is 0.1mol / L, and the molar concentration of ethylene glycol is 0.01mol / L. Heat and stir in a water bath at 70°C until evaporated, dry at 110°C for 12 hours, grind the mixture into a fine powder of about 200 mesh, heat to 300°C at a heating rate of 5°C / min, and pre-calcine in an air atmosphere After 1 hour, the furnace was cooled to room temperature; then the temperature was raised to 900° C. at a rate of 5° C. / min, calcined for 3 hours, and the furnace was cooled to room temperature to prepare a metal oxide catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com