Treatment method for recycling power plant circulating water sewage

A treatment method and technology for circulating water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ion-exchanged water/sewage treatment, etc., can solve the problem of reverse osmosis output drop, pressure difference rise, desalination rate drop and other problems, to achieve the effect of reducing alkalinity and hardness, increasing concentration ratio, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

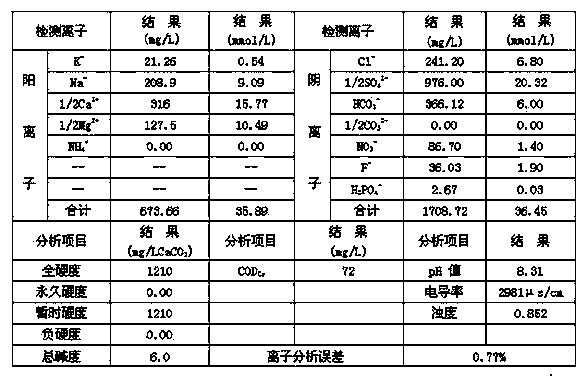

[0025] Table 1 Water quality of circulating water and sewage

[0026]

[0027] (2) Reduce the filtered water in step (1) with sodium bisulfite to make its ORP value lower than 200mV, and then send it into a two-stage sodium-type cation exchanger with a diameter of Φ2500 and a resin layer height of 2400mm , single design output 70m 3 / h, the water hardness of the second-stage sodium-type cation exchanger is lower than 10 μmol / L, and the pH value is 6.5-9.5;

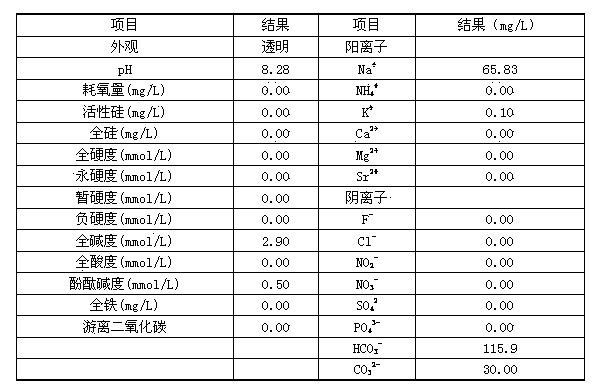

[0028] (3) Send 50%-80% of the effluent water of the sodium-type cation exchanger obtained in step (2) into the cooling water tower as circulating water replenishment, and send the remaining 20%-50% into the primary reverse osmosis system. The reverse osmosis adopts one stage and two stages, and the reverse osmosis recovery rate is 80%. See Table 2 for the influent water of the first-stage reverse osmosis (that is, the water quality of the effluent water of the second-stage sodium-type cation exchanger).

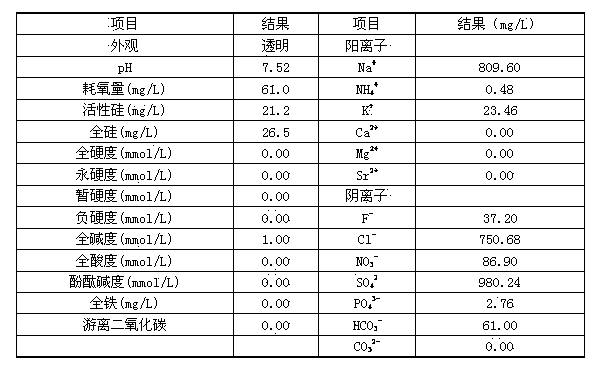

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com