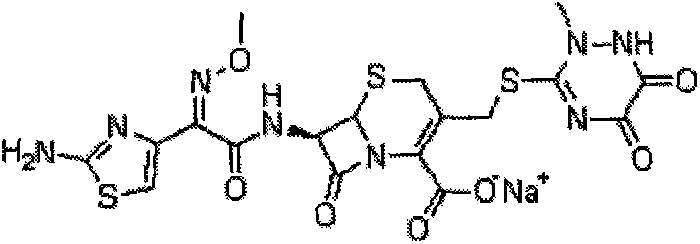

Refinement method of ceftriaxone sodium crude product

A technology of ceftriaxone sodium and a refining method, which is applied in the field of chemical pharmacy, can solve problems affecting the quality of ceftriaxone sodium, instability of ceftriaxone sodium, and high color grade of the product, so as to achieve improved safety and effectiveness and low price , The effect that the solvent is easy to get

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

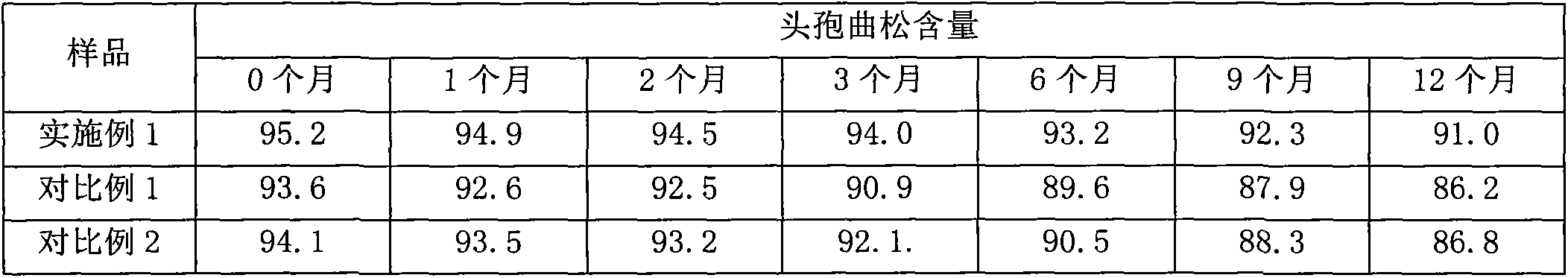

Examples

Embodiment 1

[0024] The refining method of ceftriaxone sodium, the steps are as follows:

[0025] (1) Weigh 50 g of ceftriaxone sodium crude product and 0.5 g of 3,4-difluorobenzonitrile, add 100 ml of dichloromethane, 40 ml of ethanol and 10 ml of water for injection, stir for 30 min at room temperature, add 1 g of activated carbon for decolorization 20min.

[0026] (2) The above solution is filtered through nitrogen pressure, and activated carbon and other impurities are removed by a microporous membrane. Then use the same proportion of mixed solvents to wash the suction filter flask, wash the filter cake, and transfer them to the crystallizer together.

[0027] (3) When the solution in the crystallizer reaches the crystallization temperature, start to drop fresh acetone, and after the acetone has been added dropwise, add sterile grade ceftriaxone sodium crystal seeds, and crystallize for 4 hours.

[0028] (4) Vacuum suction filtration is performed after dissolution and crystallization...

Embodiment 2

[0040] The refining method of ceftriaxone sodium, the steps are as follows:

[0041] (1) Weigh 50 g of ceftriaxone sodium crude product and 0.5 g of 3,4-difluorobenzonitrile, add 100 ml of dichloromethane, 50 ml of ethanol and 10 ml of water for injection, stir for 30 min at room temperature, add 1 g of activated carbon for decolorization 20min.

[0042] (2) The above solution is filtered through nitrogen pressure, and activated carbon and other impurities are removed by a microporous membrane. Then use the same proportion of mixed solvents to wash the suction filter flask, wash the filter cake, and transfer them to the crystallizer together.

[0043] (3) When the solution in the crystallizer reached the crystallization temperature, start to drop fresh acetone, after the acetone was added dropwise, add sterile grade ceftriaxone sodium crystal seeds, and crystallize for 5 hours.

[0044] (4) Vacuum suction filtration is performed after dissolution and crystallization, the fil...

Embodiment 3

[0046] The refining method of ceftriaxone sodium, the steps are as follows:

[0047] (1) Weigh 50 g of ceftriaxone sodium crude product and 0.5 g of 3,4-difluorobenzonitrile, add 100 ml of dichloromethane, 40 ml of ethanol and 20 ml of water for injection, stir for 30 min at room temperature, add 1 g of activated carbon for decolorization 20min.

[0048] (2) The above solution is filtered through nitrogen pressure, and activated carbon and other impurities are removed by a microporous membrane. Then use the same proportion of mixed solvents to wash the suction filter flask, wash the filter cake, and transfer them to the crystallizer together.

[0049] (3) When the solution in the crystallizer reached the crystallization temperature, start to drop fresh acetone, after the acetone was added dropwise, add sterile grade ceftriaxone sodium crystal seeds, and crystallize for 5 hours.

[0050] (4) Vacuum suction filtration is performed after dissolution and crystallization, the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com