Water-based printing ink cleaning compound and preparation method thereof

A printing ink and cleaning agent technology, which is applied in the field of water-based printing ink cleaning agent, can solve the problems of poor cleaning effect, unsatisfactory overall effect, inability to print and minimize production costs, etc., and achieves no irritating smell and a preparation method The effect of simplicity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In the preparation method of the water-based printing ink cleaning agent, each component is weighed according to the stated ratio, and at 25°C, the surfactant, the builder and the solubilizer are first added to the water, and the components are fully stirred to make the components After it is completely dissolved, add anti-redeposition agent, anti-corrosion agent, and water softener. After the dissolution is complete, filter the filtrate, and the obtained filtrate is water-based printing ink cleaning agent.

[0044] The raw materials used in the present invention are all commercially available products. In order to make the present invention easy to understand, the present invention will be further described below in conjunction with specific examples.

Embodiment 1

[0046] Water-based printing ink cleaning agent, including the following raw materials in terms of mass percentage:

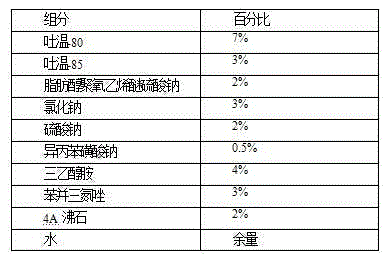

[0047] Table 1 Example 1 distribution ratio of each group

[0048]

[0049] The preparation method of this example: Weigh each component according to the above ratio, and at 25°C, first mix Tween-80, Tween-85, fatty alcohol polyoxyethylene ether sodium sulfate, sodium chloride, sodium sulfate and isopropyl Add sodium benzenesulfonate into water, stir well to make all components completely dissolved, then add triethanolamine, benzotriazole and 4A zeolite, after the dissolution is complete, filter and take the filtrate, and the obtained uniform, clear and transparent liquid is water Based printing ink cleaner.

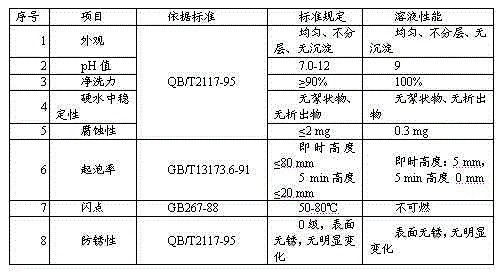

[0050] The product obtained in this embodiment is tested and analyzed, and the cleaning efficiency reaches 100%, and each index meets the standard of the national water-based cleaning agent. The specific testing data is shown in the following table 2: ...

Embodiment 2

[0054] Water-based printing ink cleaning agent, including the following raw materials in terms of mass percentage:

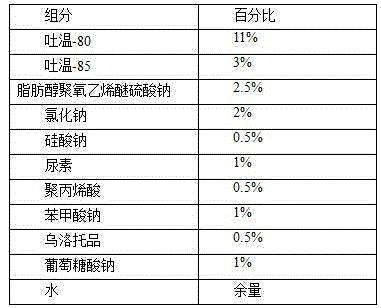

[0055] Table 3 The distribution ratio of each group in Example 2

[0056]

[0057] The preparation method of this example: Weigh each component according to the above ratio, and at 25°C, first mix Tween-80, Tween-85, fatty alcohol polyoxyethylene ether sodium sulfate, sodium chloride, sodium silicate and urea Add in water, stir well to make each component dissolve completely, then add polyacrylic acid, sodium benzoate, urotropine and sodium gluconate, after the dissolution is complete, filter and take the filtrate, the obtained uniform clear and transparent liquid is water-based Printing ink cleaner.

[0058] The product obtained in this embodiment is tested and analyzed, and the cleaning efficiency reaches 100%, and each index meets the standard of the national water-based cleaning agent. The specific testing data is shown in the following table 4:

[0059...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com