Method for increasing the yield of anaerobic digestion of sugarcane bagasse by pretreatment

A technology of anaerobic digestion and bagasse, applied in the direction of waste fuel, fermentation, etc., can solve the problem of high cost and achieve the effect of low cost, low pretreatment cost and high biogas output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, a kind of method that improves bagasse anaerobic digestion biogas production by pretreatment, carries out following steps successively:

[0047] 1) Bagasse (moisture content 24.84%) was obtained from the sugar factory of Nanning Sugar Industry Co., Ltd., Nanning City, Guangxi Province, pulverized to 10 mesh with a hammer mill, stirred and mixed to obtain bagasse fragments.

[0048] The above-mentioned bagasse was tested for indicators such as TS and VS (the testing basis is ASTM E1756-08); the specific data are as follows: TS is 75.16±0.35%, and VS is 73.55±0.36%.

[0049] Note: TS stands for total solids content (wet basis), VS stands for volatile solids content (dry basis).

[0050] 2), bagasse scrap pretreatment:

[0051] method one,

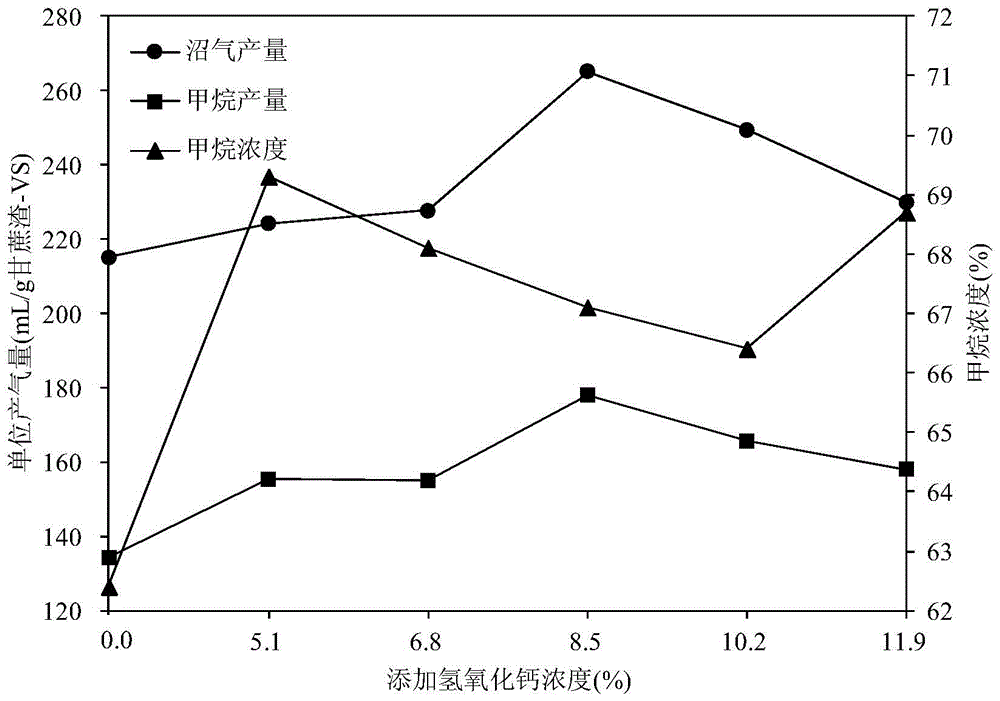

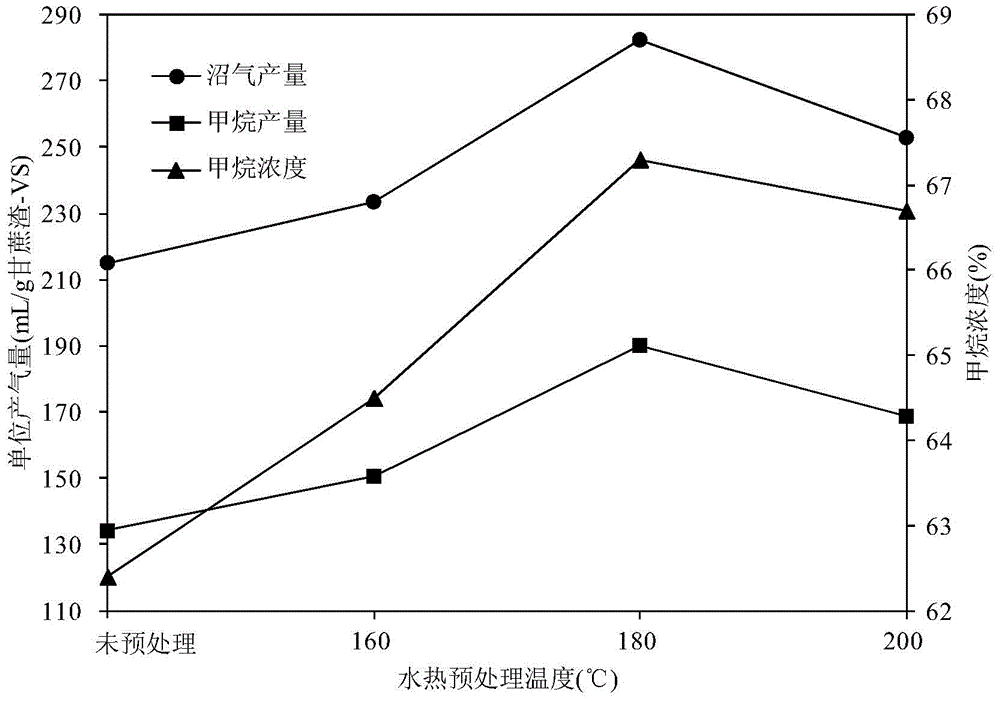

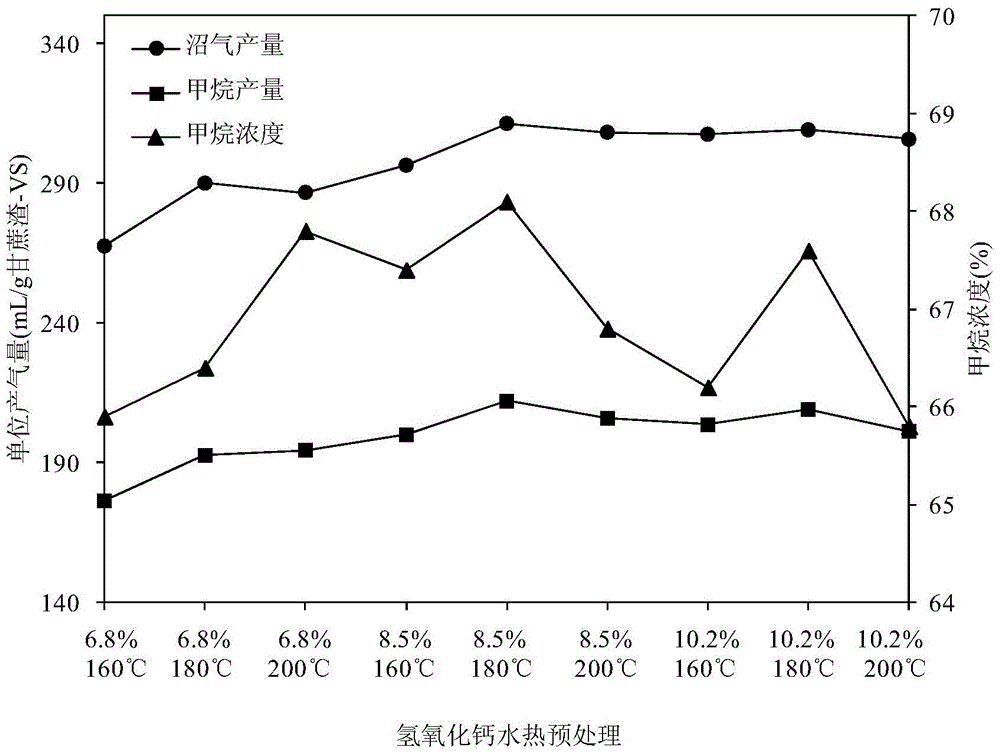

[0052] Add 2.55g of calcium hydroxide solids into 250g (250mL) of water, weigh 50.0g of bagasse scraps, and slowly add the bagasse scraps while stirring the calcium hydroxide solids in the water, so that the calcium hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com