Preparation method of mannitol-silica core-shell structured PCM (phase-change material) microcapsule

A technology of silica and core-shell structure, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of thin shell layer and inability to prevent core material leakage, and achieve economical preparation process, high phase Enthalpy change and thermal cycle stability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

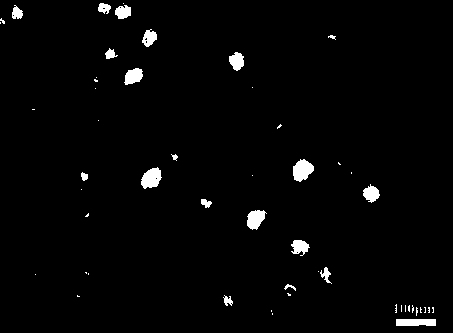

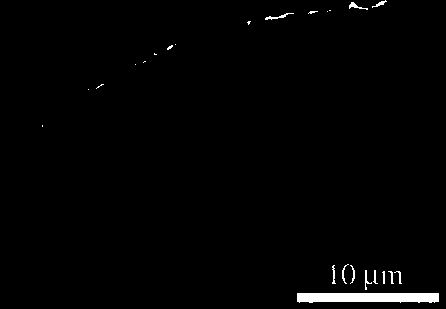

Image

Examples

preparation example Construction

[0020] The preparation method of mannitol-silica core-shell structure phase change material microcapsules includes the following steps:

[0021] 1) Mix surfactant A and organic solvent as a continuous phase at a mixing temperature of 40-80 o C, the concentration of surfactant A in the continuous phase is 0.5-3.0wt%;

[0022] 2) at 35-60 o Prepare a mannitol solution containing surfactant B as the dispersed phase under C, the concentration of the mannitol solution is 15-50wt%, and the concentration of surfactant B is 0.5-1.5wt%;

[0023] 3) Add the dispersed phase of step 2) to the continuous phase of step 1), stir and disperse for 1-100 minutes to form a stable W / O emulsion, and the volume ratio of the continuous phase to the dispersed phase is 1-100:1;

[0024] 4) Slowly add silicon source precursor C and silicon source precursor D to step 3) W / O emulsion and react for more than 5 hours to obtain silica-coated mannitol aqueous microcapsules. Silicon source precursor C and The volume ...

Embodiment 1

[0033] 1) Stir and mix Span80 with 130mL cyclohexane as the continuous phase, and keep the temperature of the mixture at 40 o C, the concentration of Span80 in the continuous phase is 0.5wt%;

[0034] 2) At 35 o Prepare 30 mL of mannitol solution containing sodium lauryl sulfate at C as the dispersed phase, the concentration of mannitol is 15 wt%, and the concentration of sodium lauryl sulfate is 0.5 wt%;

[0035] 3) Add the dispersed phase of step 2) to the continuous phase of step 1) and stir at high speed for 3.5 minutes to form a stable W / O emulsion;

[0036] 4) Put 18mL Si(OC 2 H 5 ) 4 And 7.0mL H 2 N(CH 2 ) 3 Si(OC 2 H 5 ) 3 Slowly and sequentially drip into step 3) W / O emulsion, react for 5 hours to obtain silica-coated mannitol aqueous microcapsules;

[0037] 5) Use 40 o Cyclohexane of C fully washes the silica-coated mannitol aqueous microcapsules obtained in step 4), and quickly reduces its temperature to below zero;

[0038] 6) Vacuum freeze-drying for 12 hours to obtain mann...

Embodiment 2

[0040] 1) Stir and mix Span80 with 130mL n-hexane as the continuous phase and keep the temperature of the mixture at 80 o C, the concentration of Span80 in the continuous phase is 3.0wt%;

[0041] 2) At 60 o Prepare 13 mL of mannitol solution containing sodium lauryl sulfate at C as the dispersed phase, the concentration of mannitol is 50 wt%, and the concentration of sodium lauryl sulfate is 1.5 wt%;

[0042] 3) Add the dispersed phase of step 2) to the continuous phase of step 1) and stir at high speed for 1 minute to form a stable W / O emulsion;

[0043] 4) Add 3.9mL SiCl 4 And 26mL H 2 N(CH 2 ) 3 Si(OCH 3 ) 3 Slowly and sequentially drip into step 3) W / O emulsion, react for 6 hours to obtain silica-coated mannitol aqueous microcapsules;

[0044] 5) Use 80 o Fully wash the silica-coated mannitol aqueous microcapsules obtained in step 4) with n-hexane in C, and quickly reduce its temperature to below zero;

[0045] 6) Vacuum freeze-drying for 12 hours to obtain mannitol-silica core-she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com