Drawing oil containing talcum powder

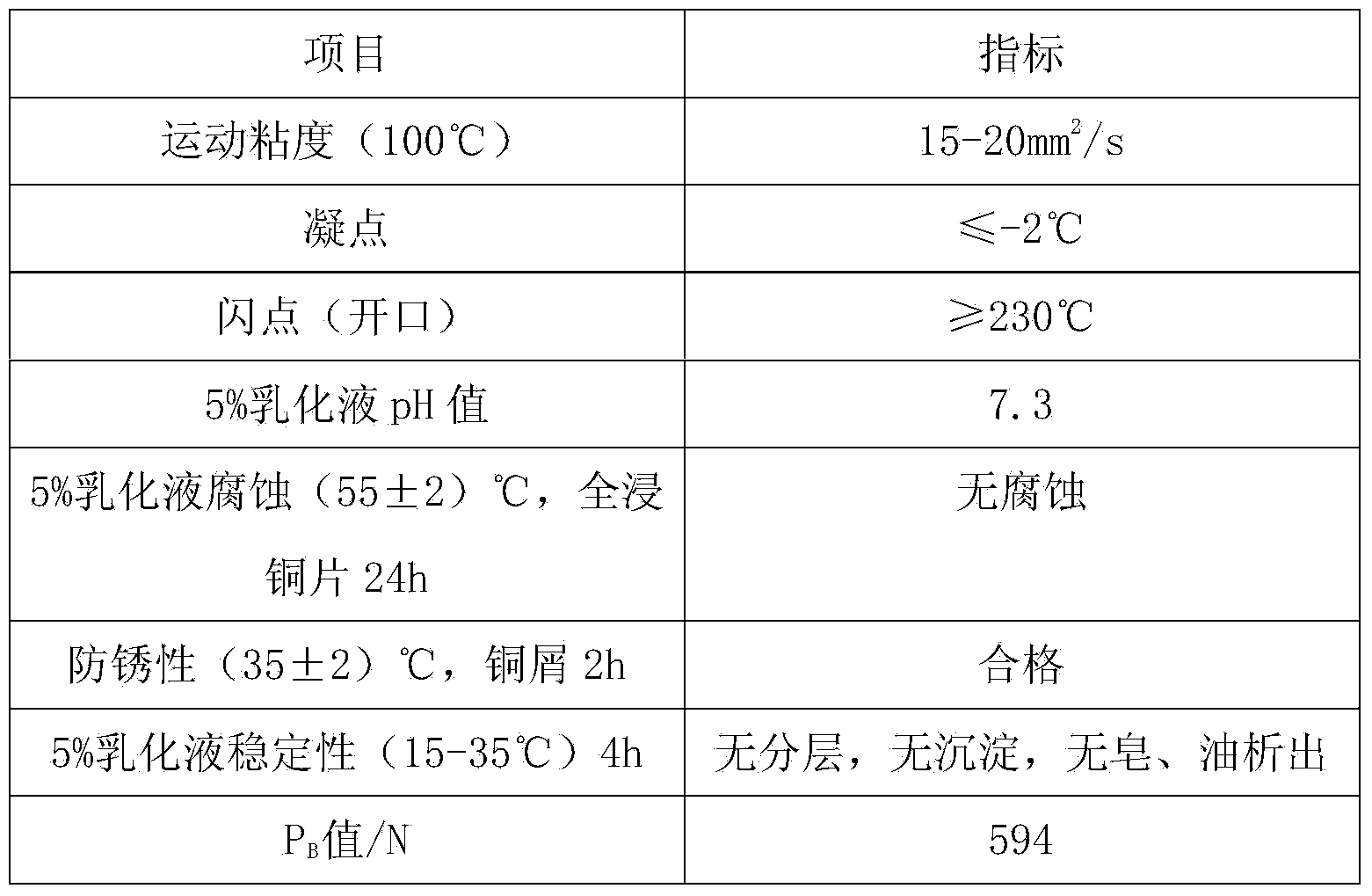

A wire drawing oil and talcum powder technology, which is applied in the petroleum industry, lubricating compositions, additives, etc., can solve problems such as difficulty in meeting the requirements of metal wire wire drawing and drawing process, unsatisfactory lubricating effect, and difficulty in cleaning and removing chips, etc., to achieve Good fluidity, increased thermal stability, and storage-resistant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0010] The drawing oil in this embodiment is made from the following raw materials in parts by weight (kg): cottonseed oil 140, hydrogenated polyisobutylene 40, glyceryl trioleate 5, polydimethylsiloxane 0.5, zinc dialkyldithiophosphate 2. Glyceryl monostearate 10, talcum powder 1, alkyl imidazoline quaternary ammonium salt 2, silane coupling agent KH5500.01, auxiliary agent 3; the auxiliary agent is made of the following raw materials in parts by weight: Butyl fatty acid 15, graphene 1, sodium metasilicate 2, xanthan gum 10, lauryl alcohol polyoxyethylene ether 4, deionized water in an appropriate amount; the preparation method is: first add lauryl alcohol polyoxyethylene to butyl stearate Oxyethylene ether and graphene were stirred at 1500 rpm for 20min to make an emulsion for subsequent use, then xanthan gum was mixed with an appropriate amount of deionized water to prepare an aqueous solution of xanthan gum with a mass concentration of 70%, and finally Mix the aqueous solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com