Pure tin electroplating solution for inhibiting growth of tin whiskers and application thereof

A tin electroplating and tin whisker technology, which is applied in the field of metal coating electrodeposition preparation, can solve the problems of easy Sn whisker growth, high welding temperature, coarse crystallization, etc., and achieve strong practical value, good flexibility and ductility, and good coating cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

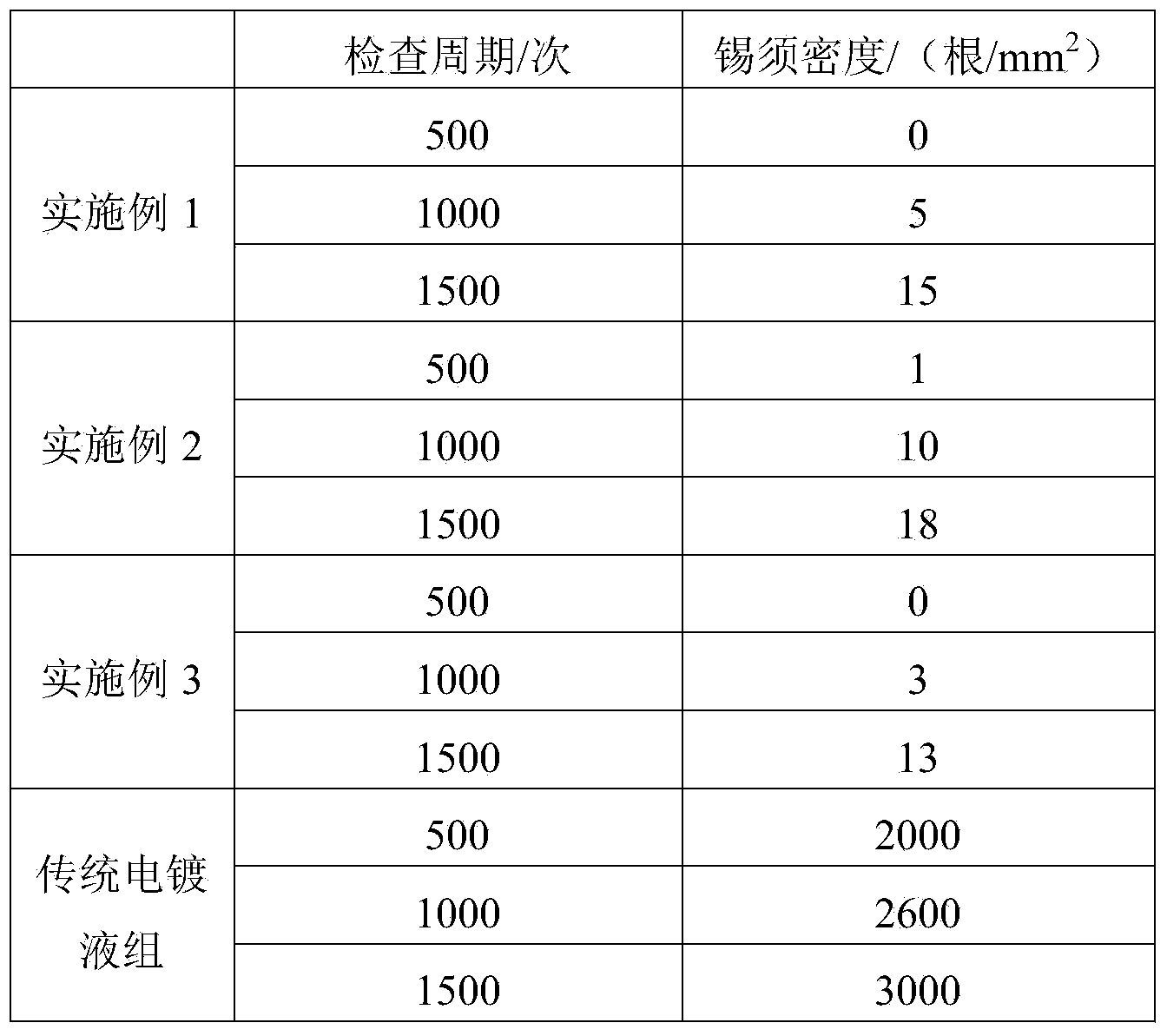

Examples

Embodiment 1

[0018] A pure tin electroplating solution that reduces the growth of tin whiskers, the specific formula is as follows, wherein the percentages are mass percentages:

[0019] 20% volume ratio is a mixed solution of methanesulfonic acid and sulfuric acid of 3:1;

[0020] The volume ratio of 40% is the mixed solution of tin methanesulfonate and hydrogen peroxide of 5:1;

[0021] 10% mixture of ascorbic acid and complex metal ion mass ratio of 2:1;

[0022] 1% 5-chlorouracil;

[0023] 5% brightener, the mass ratio is the mixture of 15g / L malic acid, 8mL / L lactic acid, 8g / L polyethylene glycol, boric acid, benzyldiacetone in a mass ratio of 1:1:2:2:1, wherein The mass ratio of polyethylene glycol, boric acid, and benzyldiacetone is 1:2:1;

[0024] 5% anionic wetting agent;

[0025] 5% sodium alkylaryl sulfonate;

[0026] water balance.

[0027] A kind of application of the above-mentioned pure tin electroplating solution that reduces the growth of tin whiskers is as follows: ...

Embodiment 2

[0029] A pure tin electroplating solution that reduces the growth of tin whiskers, the specific formula is as follows, wherein the percentages are mass percentages:

[0030] 50% volume ratio is a mixed solution of methanesulfonic acid and sulfuric acid of 3:1;

[0031] 10% volume ratio is a mixed solution of tin ethanesulfonate and hydrogen peroxide at a volume ratio of 7:1;

[0032] 10% citric acid and complex metal ion mass ratio is the mixture of 4:1;

[0033] 5% 4-acetylcytosine;

[0034] 1% brightener, the mass ratio is the mixture of 15g / L malic acid, 8mL / L lactic acid, 8g / L polyethylene glycol, boric acid, benzyldiacetone in mass ratio of 1:1:2:2:1, wherein The mass ratio of polyethylene glycol, boric acid, and benzyldiacetone is 1:2:1;

[0035] 1% anionic wetting agent;

[0036] 1% secondary alkyl sodium sulfate;

[0037] water balance.

[0038] A kind of application of the above-mentioned pure tin electroplating solution that reduces the growth of tin whiskers i...

Embodiment 3

[0040] A pure tin electroplating solution that reduces the growth of tin whiskers, the specific formula is as follows, wherein the percentages are mass percentages:

[0041] 35% volume ratio is a mixed solution of methanesulfonic acid and sulfuric acid of 3:1;

[0042] 25% mixed solution of tin 2-propanesulfonate and hydrogen peroxide;

[0043] 5% mixture of lactic acid and complexed metal ions with a mass ratio of 3:1;

[0044] 3% 2-aminoadenine;

[0045] 3% brightener, a mixture of 15g / L malic acid, 8mL / L lactic acid, 8g / L polyethylene glycol, boric acid, and benzyldiacetone in a mass ratio of 1:1:2:2:1, wherein The mass ratio of polyethylene glycol, boric acid, and benzyldiacetone is 1:2:1;

[0046] 3% anionic wetting agent;

[0047] 3% sodium alkyl sulfate;

[0048] water balance.

[0049] A kind of application of the above-mentioned pure tin electroplating solution that reduces the growth of tin whiskers is as follows: add half of the required amount of water in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com