Photosensitive conductive paste

A conductive paste, photosensitive technology, applied in the direction of conductive coating, conductive pattern formation, optics, etc., can solve the problems of increased resistance, poor storage stability of paste coating film, easy peeling, etc., to achieve good adhesion and preservation good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

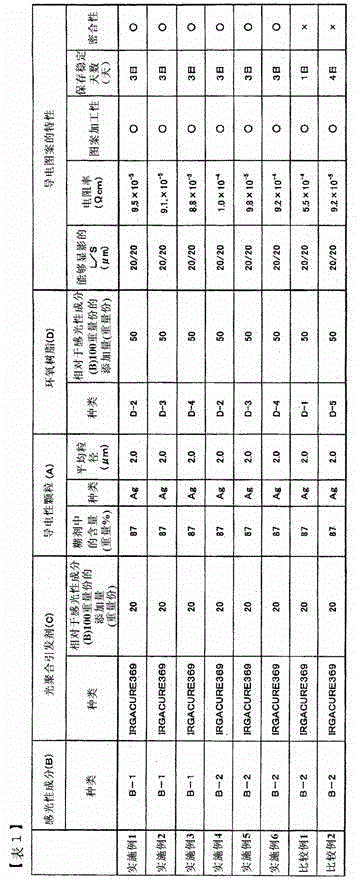

[0070] Hereinafter, examples of the present invention will be described, but the present invention is not limited to these examples. Materials and evaluation methods used in Examples and Comparative Examples are as follows.

[0071]

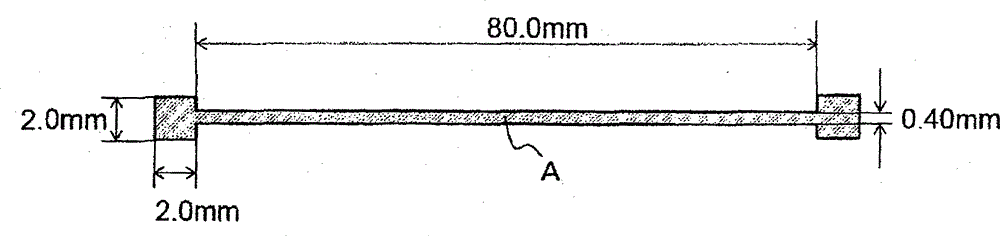

[0072] Coat the photosensitive conductive paste on the PET film in such a way that the dry thickness reaches 10 μm, and dry it in a drying oven at 90°C for 10 minutes. The arrayed linear group was used as one unit, exposed and developed through a photomask having nine types of units with different L / S values, and cured at 140° C. for 1 hour to obtain a conductive pattern. The L / S value of each cell was set to 50 / 50, 40 / 40, 30 / 30, 25 / 25, and 20 / 20 (line width (μm) / space (μm) respectively). The pattern was observed with an optical microscope, and a pattern having the minimum L / S value without residue and pattern peeling was confirmed between the patterns, and the minimum L / S value was defined as the developable L / S.

[0073]

[0074] Coat the...

Synthetic example 1

[0089] (Synthesis Example 1) Photosensitive Component (B-1)

[0090] Copolymer of ethyl acrylate (EA) / 2-ethylhexyl methacrylate (2-EHMA) / styrene (St) / acrylic acid (AA) (copolymerization ratio: 20 parts by weight / 40 parts by weight / 20 parts by weight parts / 15 parts by weight) addition reaction of 5 parts by weight of glycidyl methacrylate (GMA)

[0091] 150 g of diethylene glycol monoethyl ether acetate was put into the reaction container of nitrogen atmosphere, and it heated up to 80 degreeC using the oil bath. Spending 1 hour thereto, 20 g of ethyl acrylate, 40 g of 2-ethylhexyl methacrylate, 20 g of styrene, 15 g of acrylic acid, 0.8 g of 2,2'-azobisisobutyronitrile, and diethylene glycol mono A mixture of diethyl ether acetate 10 g. After completion of the dropwise addition, a polymerization reaction was further performed for 6 hours. Thereafter, 1 g of hydroquinone monomethyl ether was added to terminate the polymerization reaction. Next, a mixture containing 5 g of gl...

Synthetic example 2

[0092] (Synthesis Example 2) Photosensitive Component (B-2)

[0093] Copolymer of ethylene oxide-modified bisphenol A diacrylate FA-324A (product name, manufactured by Hitachi Chemical Industry Co., Ltd.) / EA / AA (copolymerization ratio: 50 parts by weight / 10 parts by weight / 15 parts by weight) Components obtained by addition reaction of 5 parts by weight of glycidyl methacrylate (GMA)

[0094] 150 g of diethylene glycol monoethyl ether acetate was put into the reaction container of nitrogen atmosphere, and it heated up to 80 degreeC using the oil bath. It took 1 hour to dropwise add 50 g of ethylene oxide-modified bisphenol A diacrylate FA-324A, 20 g of ethyl acrylate, 15 g of acrylic acid, 0.8 g of 2,2'-azobisisobutyronitrile, and diethylene diacrylate. Alcohol monoethyl ether acetate 10g mixture. After completion of the dropwise addition, a polymerization reaction was further performed for 6 hours. Thereafter, 1 g of hydroquinone monomethyl ether was added to terminate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com