Polyester fiber and preparation method thereof

A technology of polyester fiber and polyethylene terephthalate, which is applied in the field of polyester fiber and its preparation, can solve the problems of polyester fiber static electricity and flame retardancy that cannot be effectively solved, and achieve a simple and controllable preparation process, Ease of industrialization, effect of improving hygroscopic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

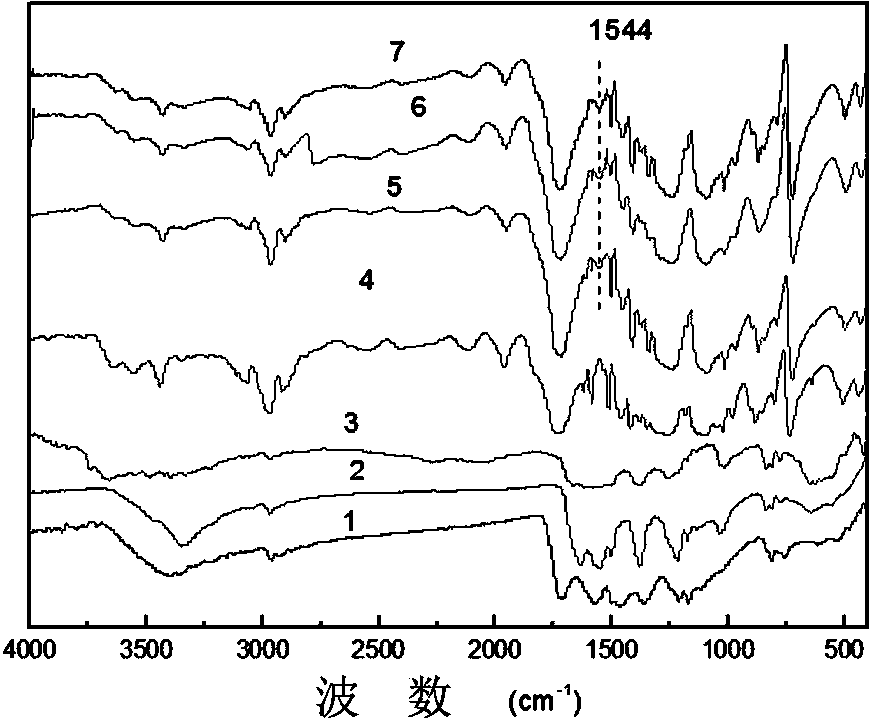

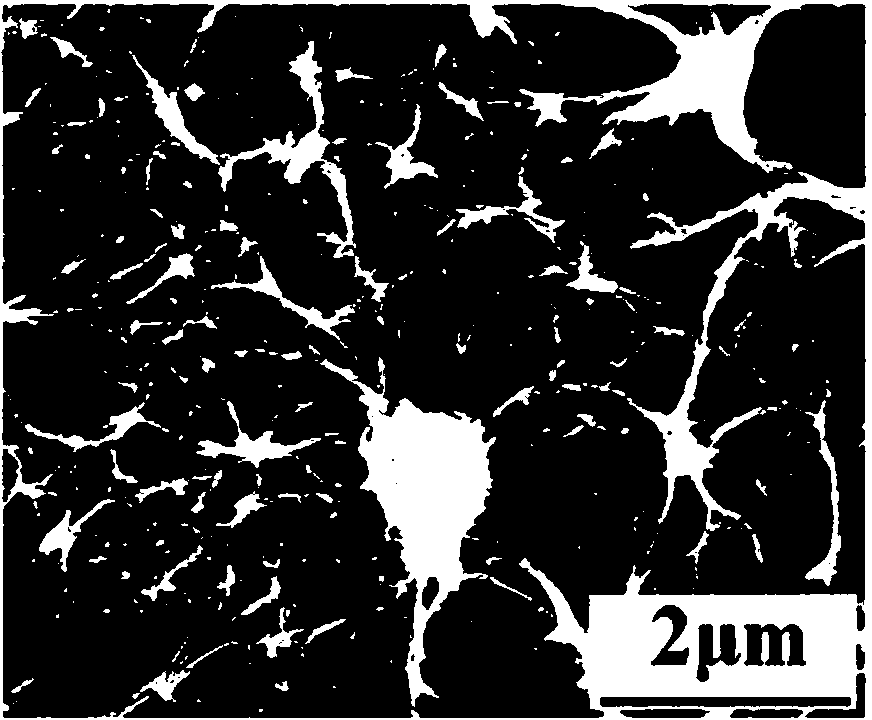

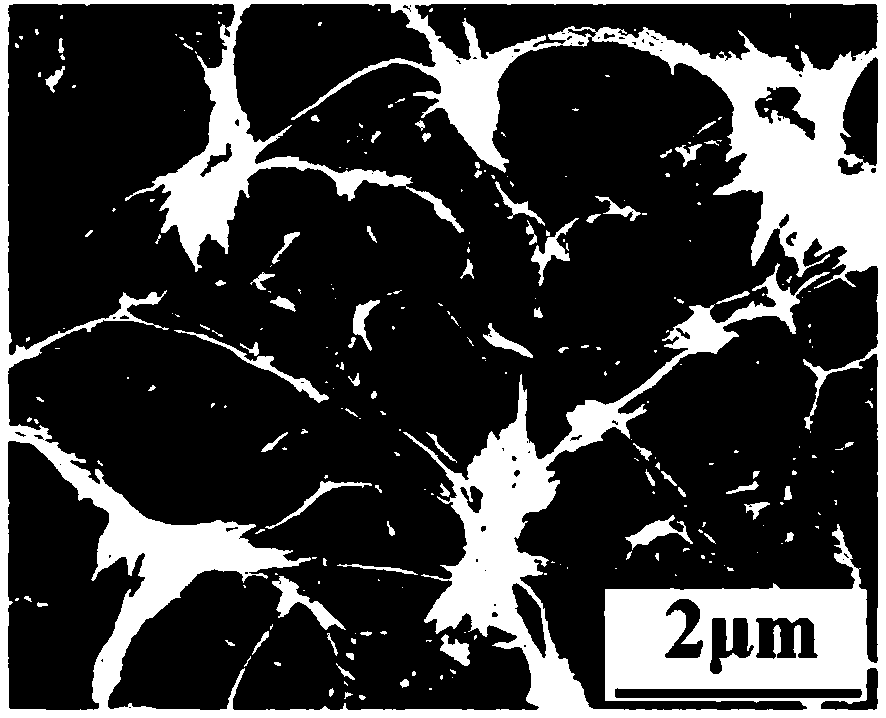

[0028] (1) Preparation of polyurea-formaldehyde-coated aligned carbon nanotube bundles: In a container equipped with a stirrer, weigh 30g of urea and 60g of formaldehyde solution (mass concentration 37-40%). After the urea is fully dissolved, slowly Heating and using triethanolamine to adjust the pH value of the solution to 8, and keeping it warm at 50°C for 1 hour to obtain a urea-formaldehyde prepolymer solution, and then adding 30g of sodium lauryl sulfate, 3000g of deionized water and 50g of oriented multi-walled carbon nano Tube bundle, after ultrasonic dispersion and mechanical stirring, set a certain stirring speed (10000rpm), adjust the pH value of the solution to 2 with hydrochloric acid solution, slowly raise the temperature, wait until the temperature rises to 45-50°C, keep it warm for 3h, and end the reaction. washing the product several times with water, suction filtering and drying to obtain polyurea-formaldehyde-coated aligned carbon nanotube bundles;

[0029] (...

Embodiment 2

[0031] (1) Preparation of polyurea-formaldehyde-coated aligned carbon nanotube bundles: In a container equipped with a stirrer, weigh 20g of urea and 40g of formaldehyde solution (mass concentration 37-40%). After the urea is fully dissolved, slowly Heating and using sodium carbonate solution to adjust the pH value of the solution to 9, keeping it warm at 70°C for 0.5h to obtain a urea-formaldehyde prepolymer solution, and then adding 5g sodium dodecylbenzenesulfonate, 2000g deionized water and 6g orientation Multi-wall carbon nanotube bundles, after ultrasonic dispersion and mechanical stirring, set a certain stirring speed (10000rpm), adjust the pH value of the solution to 4 with sulfuric acid solution, slowly raise the temperature, wait until the temperature rises to 45-50 ° C, keep it warm for 4 hours, and end reaction. washing the product several times with water, suction filtering and drying to obtain polyurea-formaldehyde-coated aligned carbon nanotube bundles;

[0032...

Embodiment 3

[0034](1) Preparation of polyurea-formaldehyde-coated aligned carbon nanotube bundles: In a container equipped with a stirrer, weigh 10% urea and 20g formaldehyde solution (mass concentration 37-40%). After the urea is fully dissolved, slowly Heating and using sodium hydroxide solution to adjust the pH value of the solution to 8, keeping it warm at 60°C for 1 hour to obtain a urea-formaldehyde prepolymer solution, and then adding 0.5g styrene-maleic anhydride copolymer, 100g deionized water and 2g Oriented multi-walled carbon nanotube bundles, after ultrasonic dispersion and mechanical stirring, set a certain stirring speed (10000rpm), adjust the pH value of the solution to 4 with citric acid solution, slowly raise the temperature, wait until the temperature rises to 45 ~ 50 ° C, keep warm for 4 hours , to end the reaction. washing the product several times with water, suction filtering and drying to obtain polyurea-formaldehyde-coated aligned carbon nanotube bundles;

[0035...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com