Method for preparing polymer thin-film solar cell active layer through electrospinning

A polymer film and solar cell technology, applied in the field of solar cells, can solve the problems of limited battery performance improvement, insufficient adhesion strength, active material falling off, etc., and achieve the effects of convenient operation, good liquid absorption rate, and strong material applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

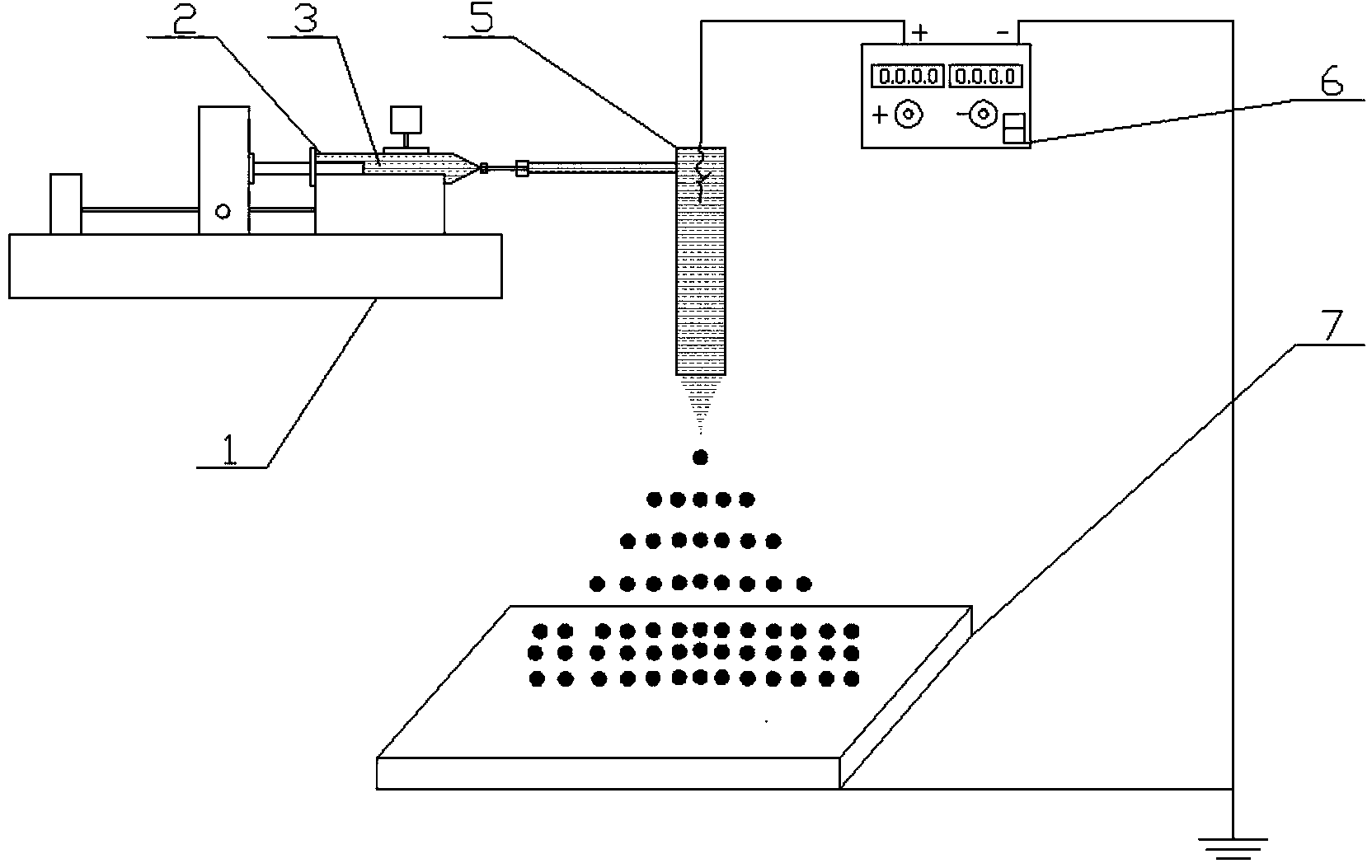

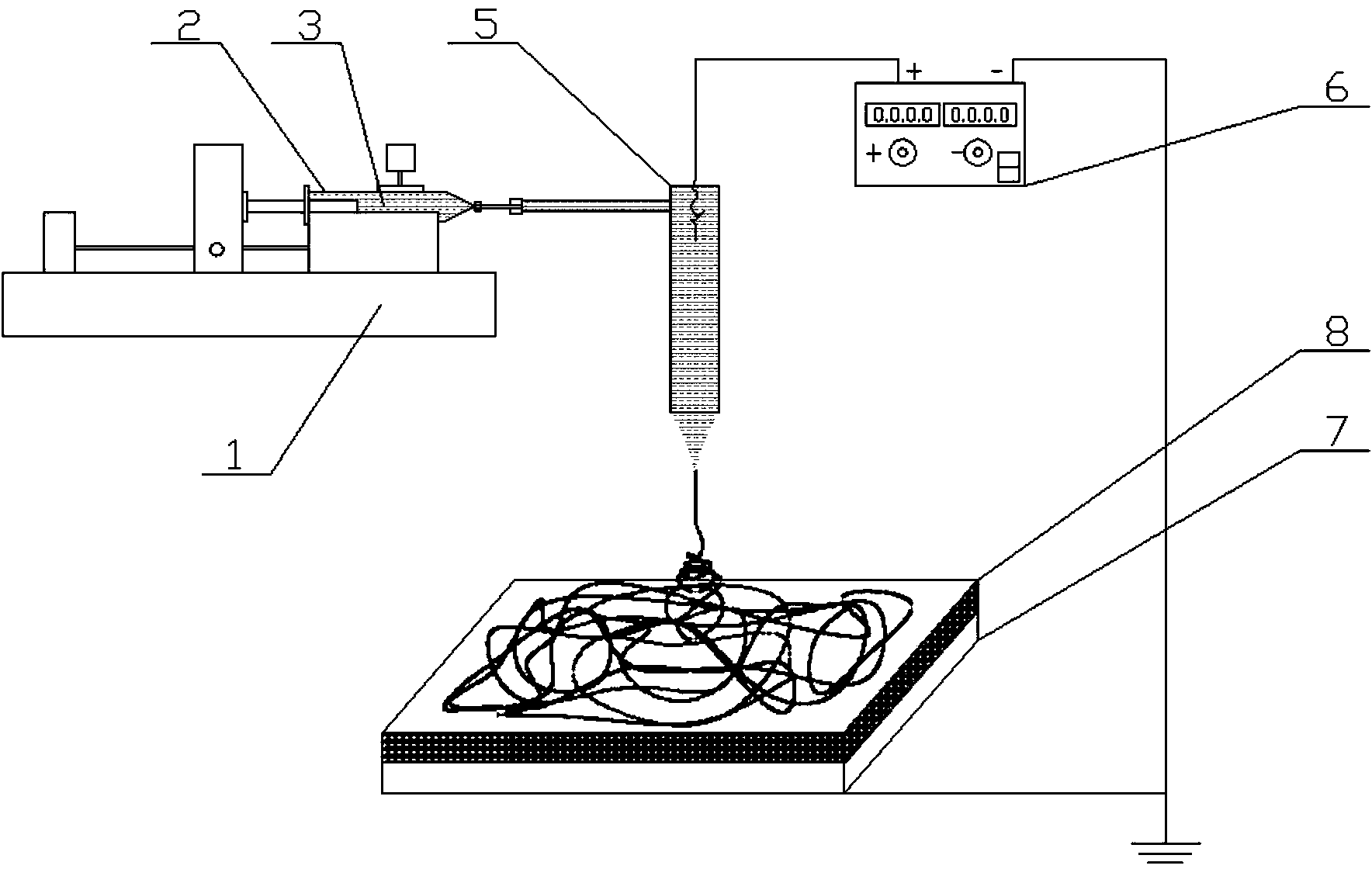

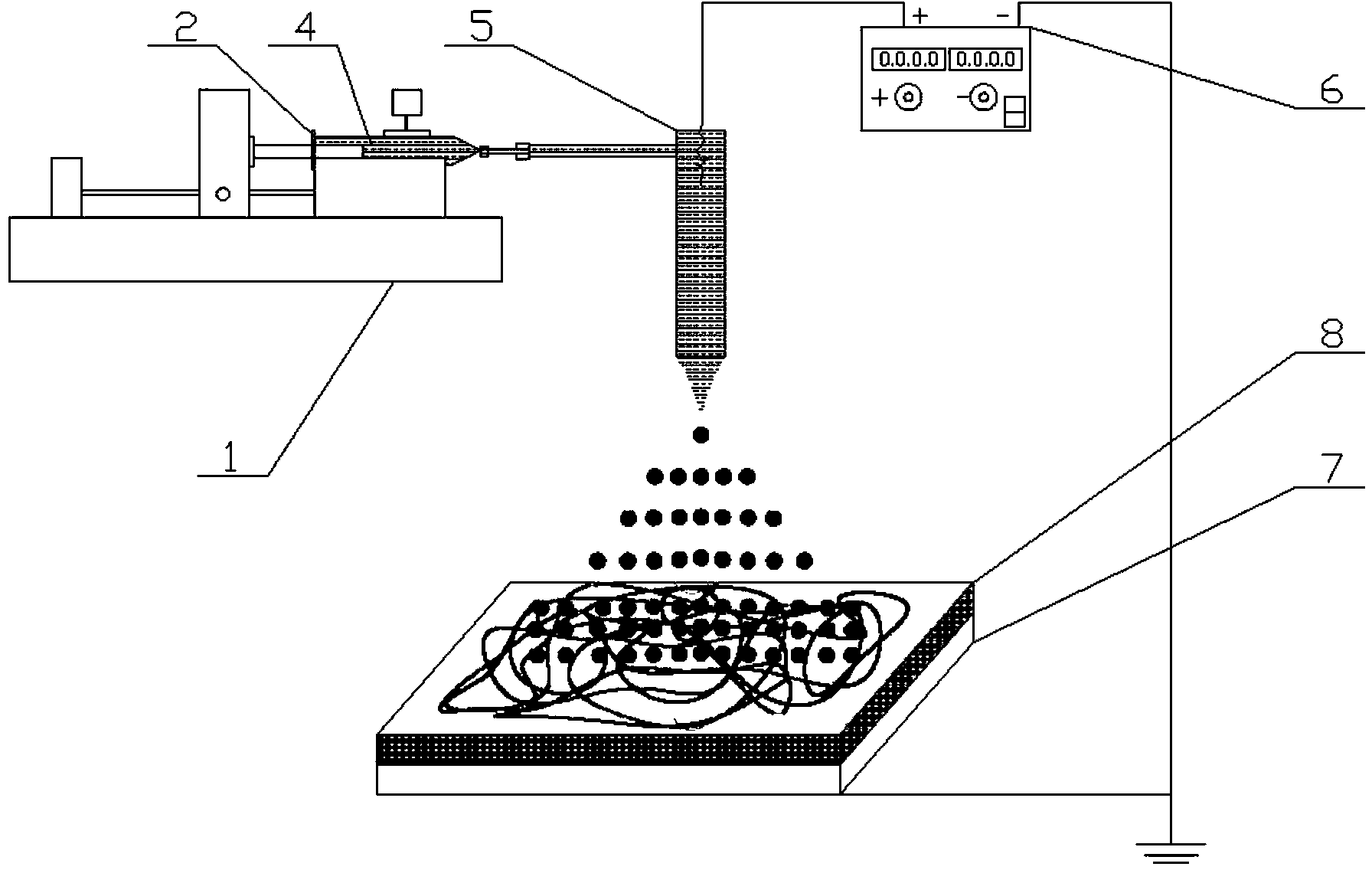

[0033] The technical solutions in the implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the scope of application of the present invention.

[0034] To prepare poly-3-hexylthiophene (P3HT) and [6,6]-2-phenyl C 61 The blend of 2-butyric acid methyl ester (PCBM) is taken as an example of the active layer, and the specific working principle and operation process of the present invention are described in detail in conjunction with the accompanying drawings.

[0035] The active layer of the polymer thin film solar battery is prepared by using the preparation method of the invention. The preparation process is as follows:

[0036] 1. Prepare the electrospinning active layer solution.

[0037] The mass concentration of the active layer solutions P3HT (donor material) and PCBM (acceptor material) used in the experime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com