A method for synchronously producing functional ingredients and powdered food from laver moss

A laver moss and functional technology, which is applied in the field of synchronous production of functional ingredients and powdered food in the laver table, can solve the problems of intolerance to storage, and achieve the effects of convenient eating, uniform color and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

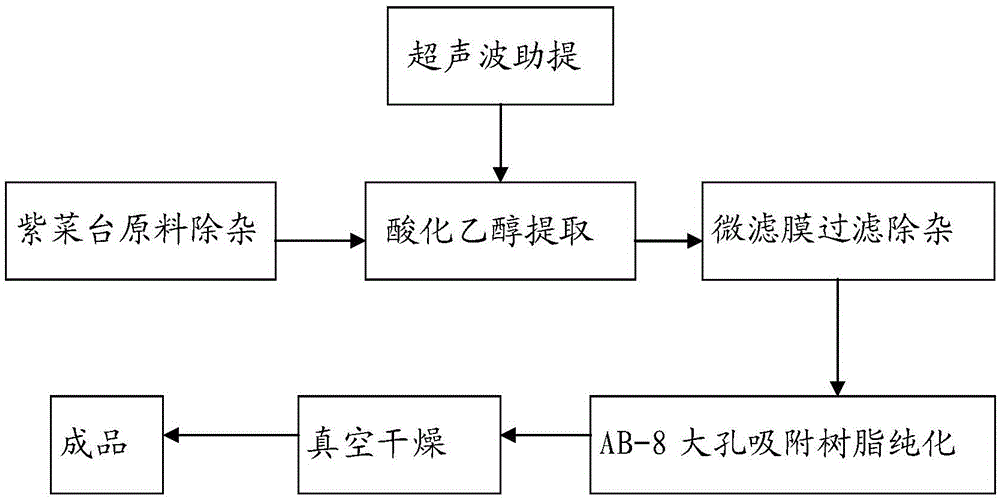

[0022] Select laver moss and wash with water to remove dirt and other impurities; place laver moss in 10 times the amount of 50% acidified ethanol (pH=3) for ultrasonic extraction, frequency 50kHz, extract twice, 0.5 hours each time, combine extraction Rotary evaporation to remove the ethanol in the extract. After filtering through a microfiltration membrane, it is purified on AB-8 macroporous adsorption resin and eluted with 70% acidified ethanol (pH=3). The eluate is concentrated and vacuum dried. Get the red pigment powder of laver moss rich in high acylated anthocyanins (see figure 1 ).

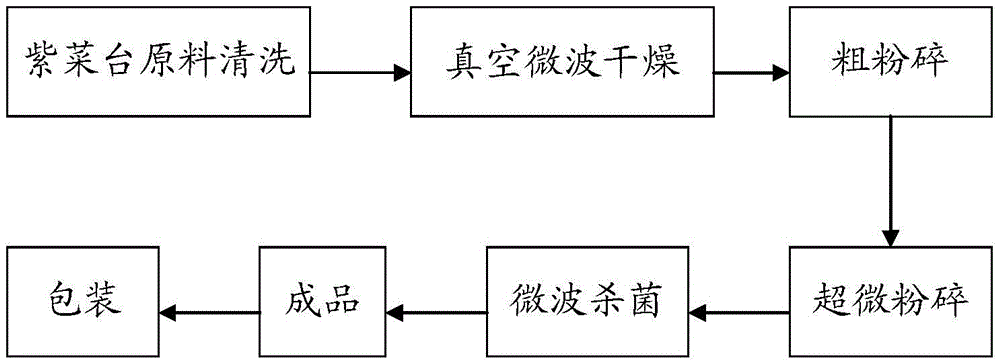

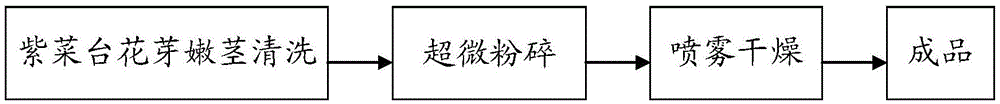

[0023] After washing and draining the whole fresh laver moss, microwave vacuum drying is carried out under the conditions of microwave power of 6.58 W / g and drying pressure of 70 KPa, and the water content is less than 2%. The dried whole plant of laver moss is pulverized, and the obtained pulverized crude product is subjected to ultra-fine pulverization. The conditions are: air inlet temper...

Embodiment 2

[0028] The preparation method of powdered laver moss functional ingredients rich in high stability acylated anthocyanins, laver moss nutritious vegetable powder, and laver moss flavor instant powder is the same as that of Example 1. The difference is that: Laver moss nutritious vegetable powder is made according to a suitable method to make laver moss vegetable nutrient full powder biscuits, which are made from the following weight raw materials: 5000g high-gluten flour, 200g laver vegetable nutrient powder, 600g soybean oil, 20g salt, 1420g white sugar , 2500g of soft water, 50g of baking soda.

[0029] The prepared laver moss-flavored instant powder is made into laver moss-flavored instant milk tea according to a suitable method, which is made from the following weight raw materials: laver moss flavored instant powder 170g, white sugar 270g, plant powder 260g, whole milk powder 150g, AK sugar 2.5g and 2g of citric acid powder.

Embodiment 3

[0031] The preparation method of powdered laver moss functional ingredients rich in high stability acylated anthocyanins, laver moss nutritious vegetable powder, and laver moss flavor instant powder is the same as that of Example 1. The difference is that: Laver moss nutritious vegetable powder is made according to a suitable method to make laver moss vegetable nutrient full powder mooncake filling, which is made of the following raw materials: 200g laver moss vegetable nutrient powder, 80g red beans, 100g white sugar, and 40g butter.

[0032] The prepared laver moss flavored instant powder is prepared into laver moss flavored instant soy milk solid beverages according to a suitable method, which is prepared from the following weight materials: laver moss flavor instant powder 150g, soybean powder 200g, white sugar 230g, and milk powder 320g.

[0033] Attached Table 1: Sensory Evaluation Table of Whole Noodles with Laver Moss Nutritional Vegetables

[0034]

[0035] Attached Table 2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com