Upconversion composite nano-material as well as preparation method and application thereof

A composite nanomaterial and composite nanoparticle technology, which is applied in the directions of wave energy or particle radiation treatment materials, drug combinations, and pharmaceutical formulations, can solve the problems of unsuitability for luminescence, heat generation, and low luminous efficiency, and achieve stable luminescence and a simple method. , the effect of high fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

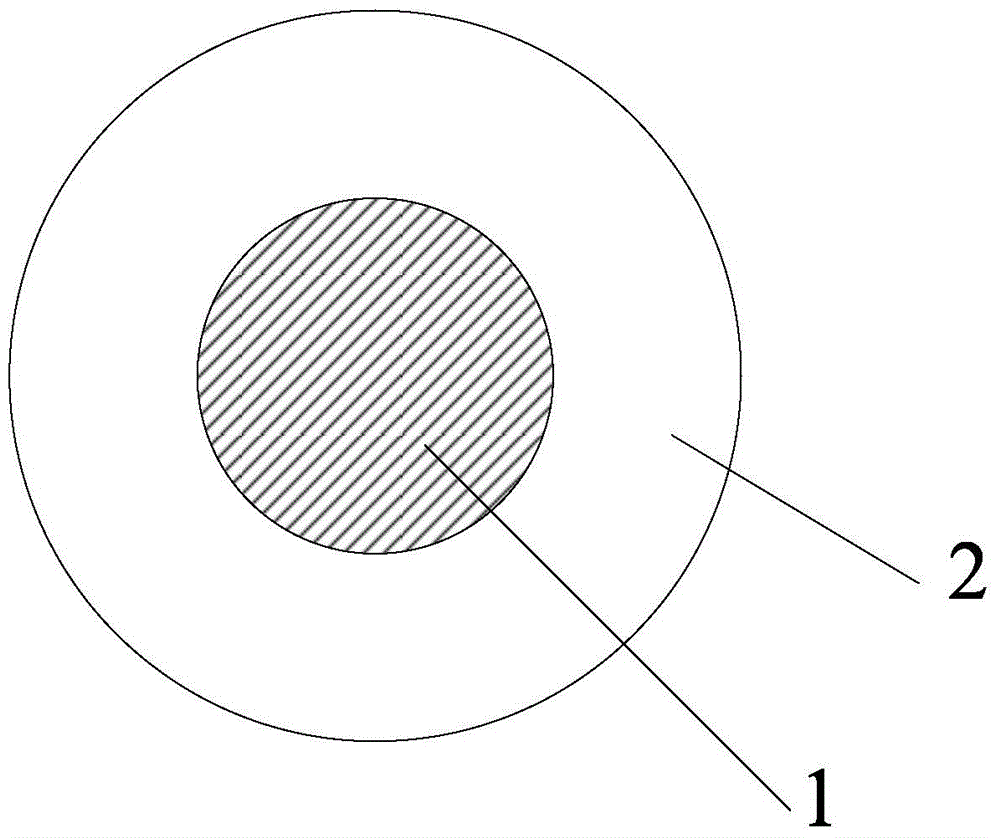

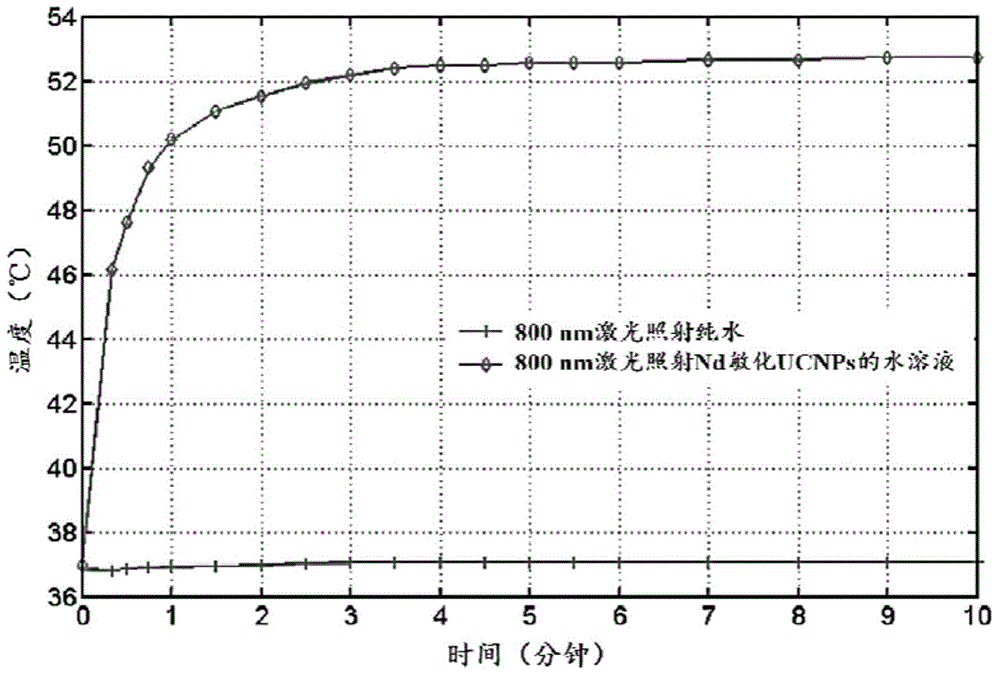

[0054] Such as figure 1 As shown, the up-conversion composite nanoparticles synthesized in this example are monodisperse nanoparticles with uniform size, and the size is 20-30 nm. The core heating layer of nanoparticles is NaYF 4 :90%Nd 3+ , the excitation wavelength is 800nm. The outer light-emitting layer is NaYF excited by 980nm laser 4 :20%Yb 3+ ,2%Er 3+ . Its concrete preparation method is as follows:

[0055] (1) Add 22.58mg of yttrium oxide and 302.8mg of neodymium oxide into a 100mL round-bottomed flask, add 2mL of concentrated hydrochloric acid to react, and then rotate to dryness.

[0056] (2) Add 9 mL of oleic acid and 9 mL of 1-octadecene. The solution was stirred and heated to 110°C under vacuum for 40 minutes.

[0057] (3) Then lower the temperature to 75°C, add 760 mg of solid sodium oleate and 148 mg of anhydrous ammonium fluoride. Then the solution was heated to 320°C and reacted for 80 minutes.

[0058] (4) After rapidly cooling to 75°C, add 9mL of...

Embodiment 2

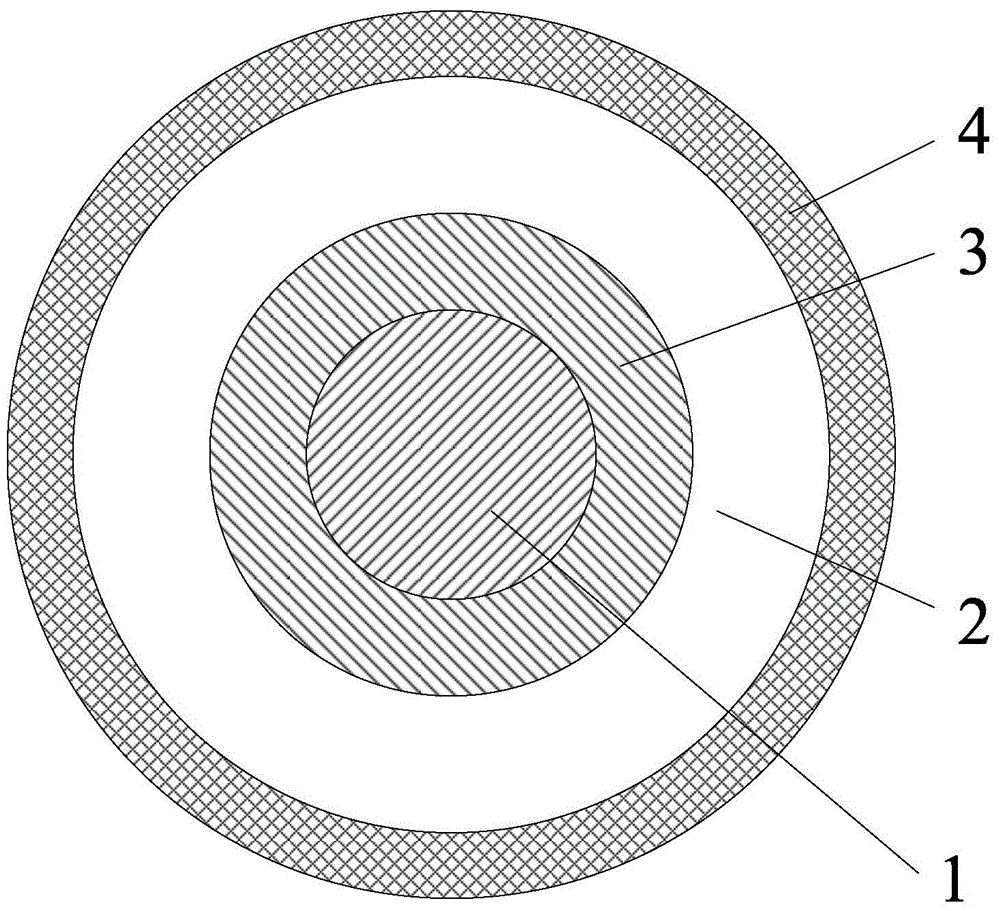

[0065] Present embodiment except following feature other structures are with embodiment 1: as image 3 As shown, the up-conversion composite nanoparticles synthesized in this example have a 4-layer structure, and the first layer of core heating layer is NaYF 4 :90%Nd 3+ , the second layer is an isolation layer used to prevent energy quenching, specifically NaYF 4 , the third light-emitting layer is NaYF 4 :30%Nd 3+ ,0.5%Er 3+ ,1%Nd 3+ , while the shell of the fourth light-emitting layer is NaYF 4 :1%Nd 3+ , used to enhance the luminous intensity. Its concrete preparation method is as follows:

[0066] (1) Add 22.58mg of yttrium oxide and 302.8mg of neodymium oxide into a 100mL round-bottomed flask, add 2mL of concentrated hydrochloric acid to react, and then rotate to dryness.

[0067] (2) Add 6.06mL of oleic acid, 4.82mL of oleylamine and 9mL of 1-octadecene. The solution was stirred and heated to 110°C under vacuum for 40 minutes.

[0068] (3) Then lower the tempe...

Embodiment 3

[0083] Present embodiment except following feature other structures are with embodiment 1: as Figure 5 As shown, the up-conversion composite nanoparticles synthesized in this example have a three-layer structure, and the first layer of core heating layer is NaYF 4 :90%Nd 3+ , the second layer is an isolation layer used to prevent energy quenching, specifically NaYF 4 , the third light-emitting layer is NaYF 4:30%Nd 3+ ,0.5%Er 3+ ,1%Nd 3+ . Its specific preparation method is exactly the same as (1)-(12) of embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com