Phase-change heat storage insulation coating based on phase-change heat storage as well as preparation method and application of coating

A thermal insulation coating and phase-change heat storage technology, which is applied in the field of wall thermal insulation coatings and phase-change heat storage materials, can solve the problems of low thermal conductivity of phase-change microcapsules, slow heat storage and release rate, and easy leakage, and achieve excellent performance. Heat storage and insulation performance, improvement of thermal comfort, and effect of reducing building energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

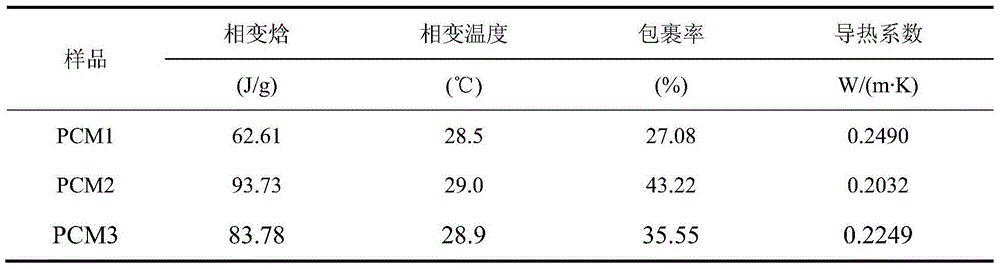

Embodiment 1

[0026] Add 20g of secondary deionized water into the three-necked flask, adjust the pH to 2 with hydrochloric acid, add 10ml of ethanol, 10.4g of tetraethyl orthosilicate, and stir at 60°C to form a sol. Dissolve 10 g of paraffin in 100 ml of deionized water, add sodium lauryl sulfate with 1% paraffin mass, and emulsify with ultrasonic vibration to obtain a milky white emulsion. The emulsion was added dropwise to the silica sol. Continue to stir the reaction after the dropwise addition is complete. After the liquid is cooled, put it into a constant temperature bath at 0°C, stir, add 17g of tetrabutyl titanate and 40ml of ethanol dropwise, and stir to obtain a gel. After airtight aging at room temperature, filter and wash with alcohol and deionized water. After vacuum drying, paraffin / SiO 2 -TiO 2 Phase change microcapsules, named PCM1.

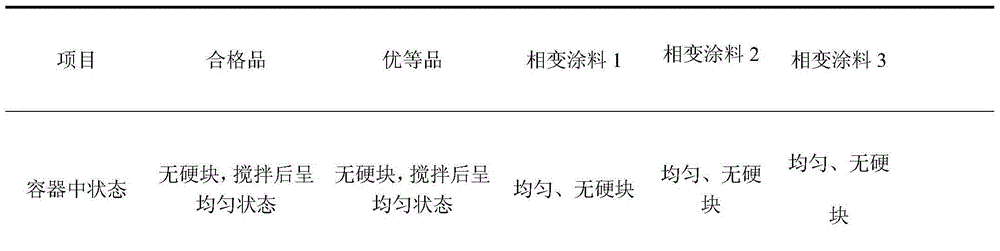

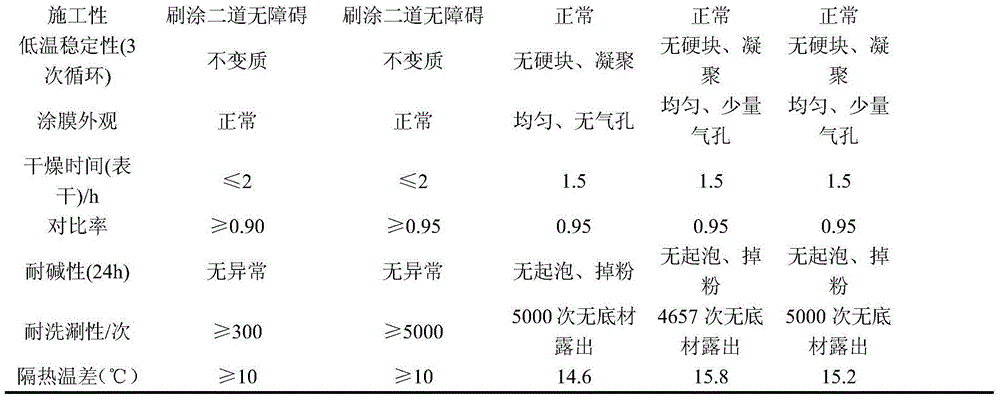

[0027] Dissolve 15g of propylene glycol and 2g of hydroxyethyl cellulose in 40g of deionized water, then add 2g of mineral oil-based def...

Embodiment 2

[0029] Add 20g of secondary deionized water into the three-necked flask, adjust the pH to 2 with hydrochloric acid, add 10ml of ethanol, 10.4g of tetraethyl orthosilicate, and stir at 60°C to form a sol. Dissolve 20 g of paraffin in 100 ml of deionized water, add sodium lauryl sulfate with 1% of the mass of paraffin, and emulsify with ultrasonic vibration to obtain a milky white emulsion. The emulsion was added dropwise to the silica sol. Continue to stir the reaction after the dropwise addition is complete. After the liquid is cooled, put it into a constant temperature bath at 0°C, stir, add 17g of tetrabutyl titanate and 40ml of ethanol dropwise, and stir to obtain a gel. After airtight aging at room temperature, filter and wash with alcohol and deionized water. After vacuum drying, paraffin / SiO 2 -TiO 2 Phase change microcapsules, named PCM2.

[0030] Dissolve 20g of propylene glycol and 5g of hydroxyethylcellulose in 60g of deionized water, then add 3g of high-viscosi...

Embodiment 3

[0032] Add 20g of secondary deionized water into the three-necked flask, adjust the pH to 2 with hydrochloric acid, add 10ml of ethanol, 10.4g of tetraethyl orthosilicate, and stir at 60°C to form a sol. Dissolve 15 g of paraffin in 100 ml of deionized water, add sodium lauryl sulfate with 1% of the mass of paraffin, and emulsify with ultrasonic vibration to obtain a milky white emulsion. Add the emulsion to the sol drop by drop, and continue to stir the reaction after the dropwise addition is completed. After the liquid is cooled, put it into a constant temperature bath at 0°C, stir, add 17g of tetrabutyl titanate and 40ml of ethanol dropwise, and stir to obtain a gel. After airtight aging at room temperature, filter and wash with alcohol and deionized water. After vacuum drying, paraffin / SiO 2 -TiO 2 Phase change microcapsules, named PCM3.

[0033] Dissolve 17g of propylene glycol and 3g of hydroxyethyl cellulose in 50g of deionized water, then add 2.5g of defoamer and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com