Environment-friendly inorganic exterior-wall heat-insulation thermal-insulation coating and preparation process thereof

A thermal insulation and inorganic technology, applied in the direction of epoxy resin coating, polyurea/polyurethane coating, coating, etc., can solve the problems of high thermal conductivity, high production cost, poor thermal insulation effect, etc., and achieve low thermal conductivity , avoid heat loss, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

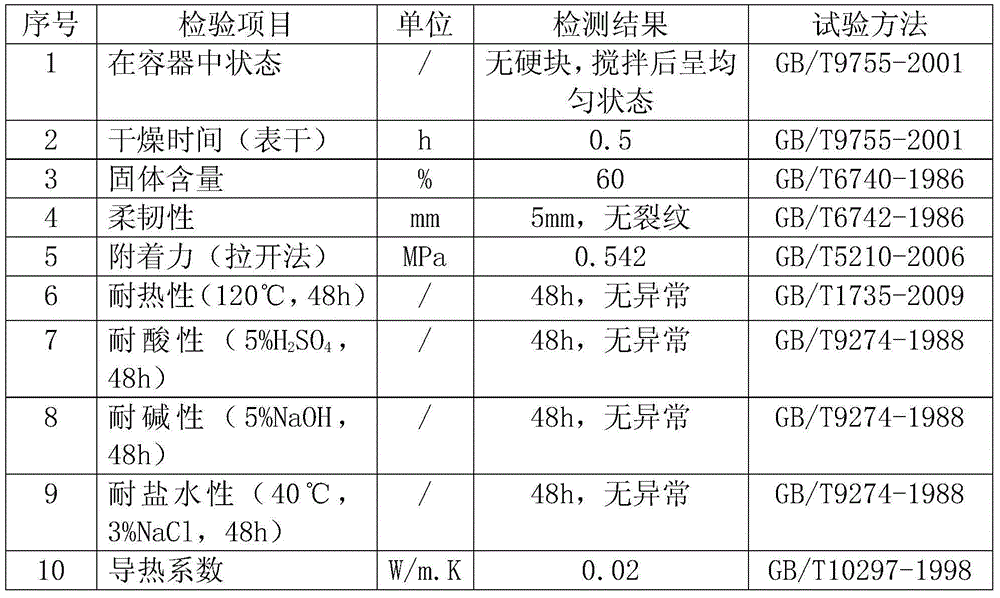

Image

Examples

Embodiment 1

[0031] A preparation process of a green inorganic exterior wall thermal insulation coating, the preparation process has the following steps:

[0032] a. Prepare the following formula components in parts by weight: 40 parts of functional fillers, 45 parts of modified polymer emulsions, 25 parts of other pigments and seasonings, 5.1 parts of auxiliary agents, and 60 parts of water; The ratio of commercially available water-based dispersants, commercially available water-based defoamers, commercially available water-based film-forming aids, commercially available water-based leveling agents and commercially available water-based thickeners is 2:0.3:2:0.3:0.5, and other pigments are 10 parts of titanium dioxide, 7 parts of zinc oxide, 8 parts of lithopone or mica powder;

[0033] Under the condition of stirring at 700-1200 rpm, add commercially available water-based dispersant among additives, 2 / 3 parts by weight of commercially available water-based defoamer, commercially availab...

Embodiment 2

[0037] A preparation process of a green inorganic exterior wall thermal insulation coating, the preparation process has the following steps:

[0038] a. Prepare the following formula components in parts by weight: 45 parts of functional fillers, 55 parts of modified polymer emulsions, 25 parts of other pigments and seasonings, 6.5 parts of additives, and 65 parts of water;

[0039] Among them, the ratio of commercially available water-based dispersants, commercially available water-based defoamers, commercially available water-based film-forming aids, commercially available water-based leveling agents and commercially available water-based thickeners in the additives is 3:0.5:2:0.4 : 0.6; Other pigments are composites of 10 parts of titanium dioxide, 7 parts of zinc oxide, and 8 parts of lithopone or mica powder.

[0040] Under the condition of stirring at 700-1200 rpm, add commercially available water-based dispersant among additives, 2 / 3 parts by weight of commercially avail...

Embodiment 3

[0044] A preparation process of a green inorganic exterior wall thermal insulation coating, the preparation process has the following steps:

[0045] a. Prepare the following formula components in parts by weight: 55 parts of functional fillers, 48 parts of modified polymer emulsions, 27 parts of other pigments and seasonings, 7.1 parts of additives, and 65 parts of water;

[0046] Among them, the ratio of commercially available water-based dispersants, commercially available water-based defoamers, commercially available water-based film-forming aids, commercially available water-based leveling agents and commercially available water-based thickeners in the additives is 3:0.5:2.1:0.5 : 1; other pigments and seasonings, a compound of 12 parts of titanium dioxide, 7 parts of zinc oxide, 8 parts of lithopone or mica powder.

[0047] Under the condition of stirring at 700-1200 rpm, add commercially available water-based dispersant among additives, 2 / 3 parts by weight of commerci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com