Method for testing content of oxygen in villaumite

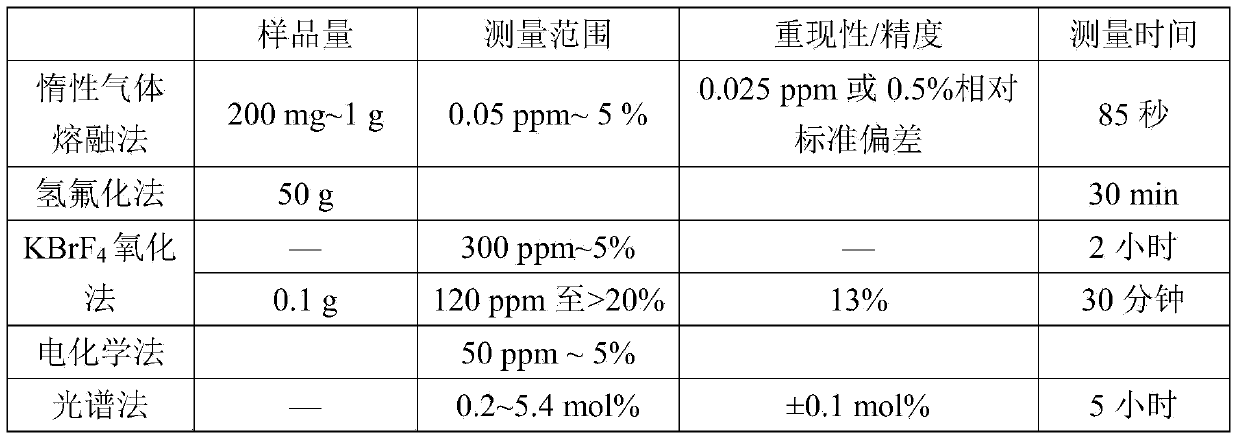

A test method and technology for oxygen content, which are applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of low relative standard deviation, low detection limit, high measurement lower limit, etc., to prevent the influence of moisture and oxygen, The effect of low relative standard deviation and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1.1 Instruments and materials

[0042] American LECO oxygen analyzer model RO600 or RO836, including halogen trap, gas system, sample injector, high temperature furnace, detection system, etc.; glove box; electronic balance; tin capsule; high-purity graphite crucible; standard sample (steel) ; LiF single crystal; NaF powder sample.

[0043] 1.2 Analytical conditions

[0044] The oxygen analyzer uses nitrogen as the power gas, and the pressure is 0.28MPa ~ 0.29MPa. High-purity argon with water and oxygen content below 1ppm is used as the carrier gas, and the pressure is 0.15MPa. The power of the high temperature furnace is set to 2900W, and the degassing cycle is 3 times.

[0045] 1.3 Operation steps

[0046] Sample preparation: Put the capsule-shaped tin capsule on the electronic balance in the glove box, fill it with about 0.15g of NaF powder sample after peeling, fold and seal the capsule-shaped tin capsule after weighing and recording;

[0047] Start-up and para...

Embodiment 2

[0056] 2.1 Instruments and materials

[0057] American LECO oxygen analyzer, including halogen trap, gas system, sample injector, high temperature furnace, detection system, etc.; glove box; electronic balance; tin bag; high-purity graphite crucible; standard sample (lithium fluoride single crystal) ; LiF-NaF-KF (46.5-11.5-42 mol%) eutectic salt.

[0058] 2.2 Analysis conditions

[0059] The oxygen analyzer uses high-purity argon and high-purity nitrogen with an oxygen content of less than 1ppm as the carrier gas, the pressure is 0.15MPa and 0.28-0.29MPa respectively, the high-temperature furnace analysis power is set to 2500W, and the degassing cycle is 3 times.

[0060] 2.3 Operation steps

[0061] Sample preparation: Put the tin bag on the electronic balance in the glove box, put about 0.15g of LiF-NaF-KF powder sample into it after peeling, fold and seal the tin bag after weighing and recording;

[0062] Start-up and parameter setting: According to the operation require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com