Preparation method of benzene sensor based on anodic alumina nanowire

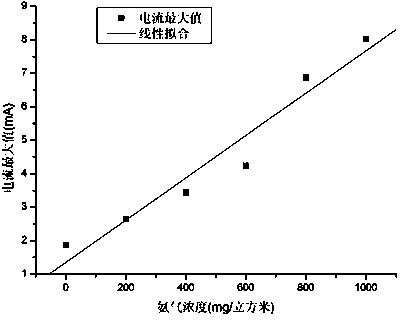

An anodized aluminum and benzene sensor technology, applied in the field of sensors, can solve the problems of high cost, long detection period, inability to achieve accurate and rapid detection of trace benzene, etc., and achieves low cost, high accuracy, repeatability and controllability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

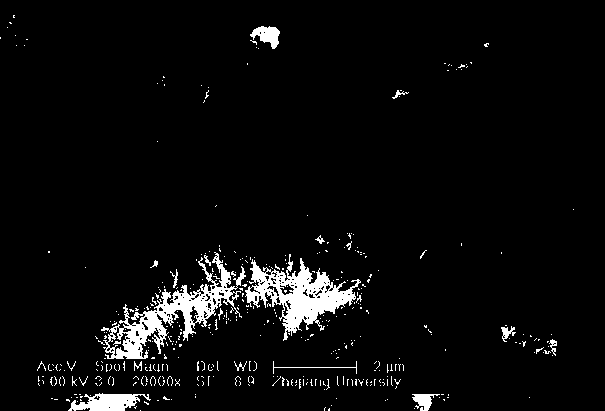

Image

Examples

Embodiment 1

[0034] A preparation method of a benzene sensor based on anodized aluminum nanowires, the preparation method comprising the following steps:

[0035] a) Pre-treatment: Anneal the high-purity aluminum plate with a purity ≥99.999% at 220°C for 8 hours, wash and degrease after cooling, and then immerse in the soaking solution. The temperature of the soaking solution is 35°C, and the soaking time is 30 minutes; take it out and wash it , after taking it out and cleaning it, perform electrochemical polishing for 5 minutes in a mixed solution of ethanol and perchloric acid with a volume ratio of 2:1 (Ra ≤ 0.01 μm); the solution used for cleaning and degreasing is a mixture of ethanol and cyclohexanol, The volume ratio of ethanol to cyclohexanol is 1:2, and the cleaning solution is ultrasonically vibrated while cleaning; the soaking solution is a mixed solution of sodium bicarbonate with a mass fraction of 10% and potassium hydroxide with a mass fraction of 2%, and sodium bicarbonate a...

Embodiment 2

[0041] A preparation method of a benzene sensor based on anodized aluminum nanowires, the preparation method comprising the following steps:

[0042] a) Pre-treatment: Anneal the high-purity aluminum plate with a purity ≥ 99.999% at 280°C for 7 hours, wash and degrease after cooling, and then immerse in the soaking solution. The temperature of the soaking solution is 45°C and the soaking time is 20 minutes; take it out and wash it , after taking it out and cleaning it, perform electrochemical polishing for 5 minutes in a mixed solution of ethanol and perchloric acid with a volume ratio of 2:1 (Ra ≤ 0.01 μm); the solution used for cleaning and degreasing is a mixture of ethanol and cyclohexanol, The volume ratio of ethanol to cyclohexanol is 1:3, and ultrasonic vibration is used to clean the washing liquid; the soaking liquid is a mixed solution of sodium bicarbonate with a mass fraction of 12% and potassium hydroxide with a mass fraction of 3%, and sodium bicarbonate and The v...

Embodiment 3

[0048] A preparation method of a benzene sensor based on anodized aluminum nanowires, the preparation method comprising the following steps:

[0049] a) Pretreatment: Anneal the high-purity aluminum plate with a purity ≥ 99.999% at 320°C for 6 hours, wash and degrease after cooling, and then immerse in the soaking solution, the temperature of the soaking solution is 50°C, and the soaking time is 10 minutes; take it out and wash it , after taking it out and cleaning it, perform electrochemical polishing for 5 minutes in a mixed solution of ethanol and perchloric acid with a volume ratio of 2:1 (Ra ≤ 0.01 μm); the solution used for cleaning and degreasing is a mixture of ethanol and cyclohexanol, The volume ratio of ethanol to cyclohexanol is 1:4, and the cleaning solution is ultrasonically vibrated while cleaning; the soaking solution is a mixed solution of sodium bicarbonate with a mass fraction of 15% and potassium hydroxide with a mass fraction of 4%, and sodium bicarbonate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com