One-dimensional rod-shaped sulfur-copper compound as well as preparation method and application thereof

A compound and rod-shaped technology is applied in the field of one-dimensional rod-shaped sulfur-copper compounds and their preparation, and achieves the effect of simple and fast synthesis method, regular morphology and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Material preparation:

[0025] Using the traditional synthesis method, a certain amount of CuSO 4 ·5H 2 O was dissolved in a certain amount of DMSO to prepare a copper sulfate solution with a concentration of 0.0075M, and a uniform light green solution was formed after stirring for 30 minutes. Put the solution in a reaction kettle, put it in a blast oven, heat up to 180°C naturally, react at this temperature for 6h, and take out the material when it drops to room temperature. The black copper sulfide active material can be obtained by repeated centrifugal washing (the washing solvent is preferably carbon tetrachloride).

[0026] Material Characterization:

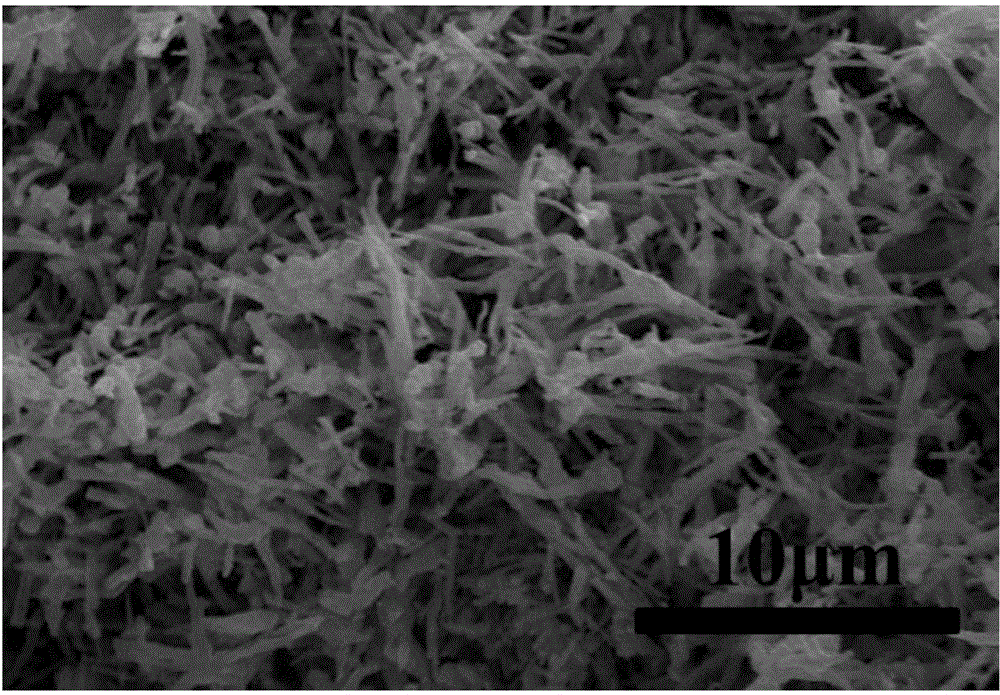

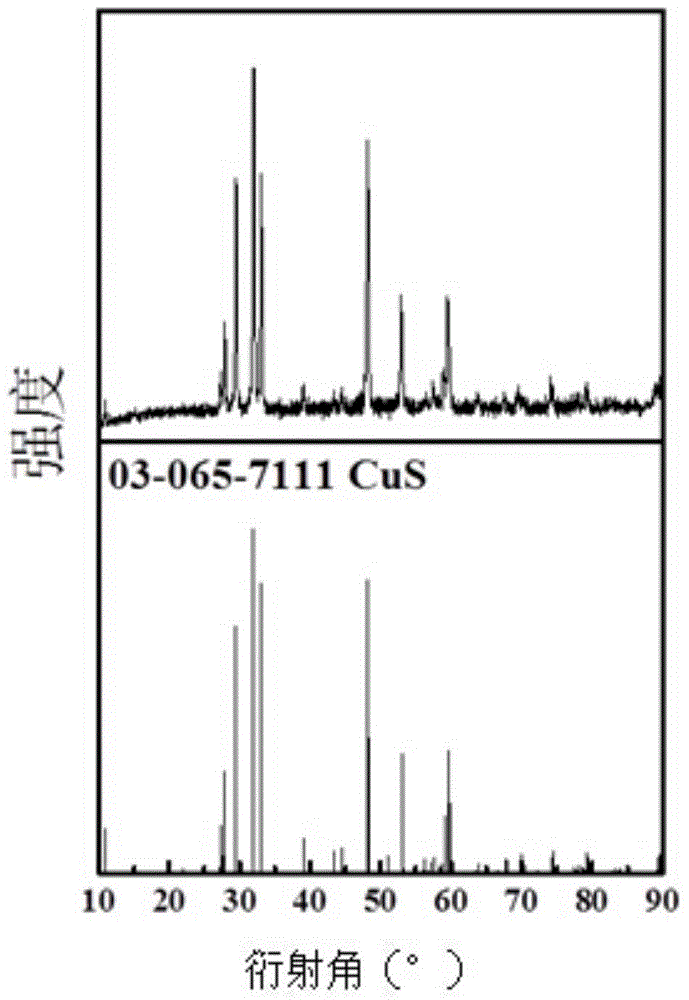

[0027] Using a scanning electron microscope (HITACHI S-4800) to analyze the particle size of the material, it was obtained figure 1 , it can be seen from the figure that the electrode material is a one-dimensional nanorod, and the diameter of the nanorod is about 100 nm. The crystal structure of the material is ...

Embodiment 2

[0032] Material preparation:

[0033] Using the traditional synthesis method, a certain amount of CuSO 4 ·5H 2 O was dissolved in a certain amount of DMSO to prepare a copper sulfate solution with a concentration of 0.02mol / l, and a uniform light green solution was formed after stirring for 30 minutes. Put the solution in a reaction kettle, put it in a blast oven, heat up to 180°C naturally, react at this temperature for 6h, and take out the material when it drops to room temperature. The black copper sulfide active material can be obtained by repeated centrifugal washing (the washing solvent is preferably carbon tetrachloride).

[0034] Material Characterization:

[0035] Using a scanning electron microscope (HITACHI S-4800) to analyze the particle size of the material, it was obtained Figure 4 , it can be seen from the figure that the electrode material is a one-dimensional nanorod, and the diameter of the nanorod is about 150nm. The crystal structure of the material i...

Embodiment 3

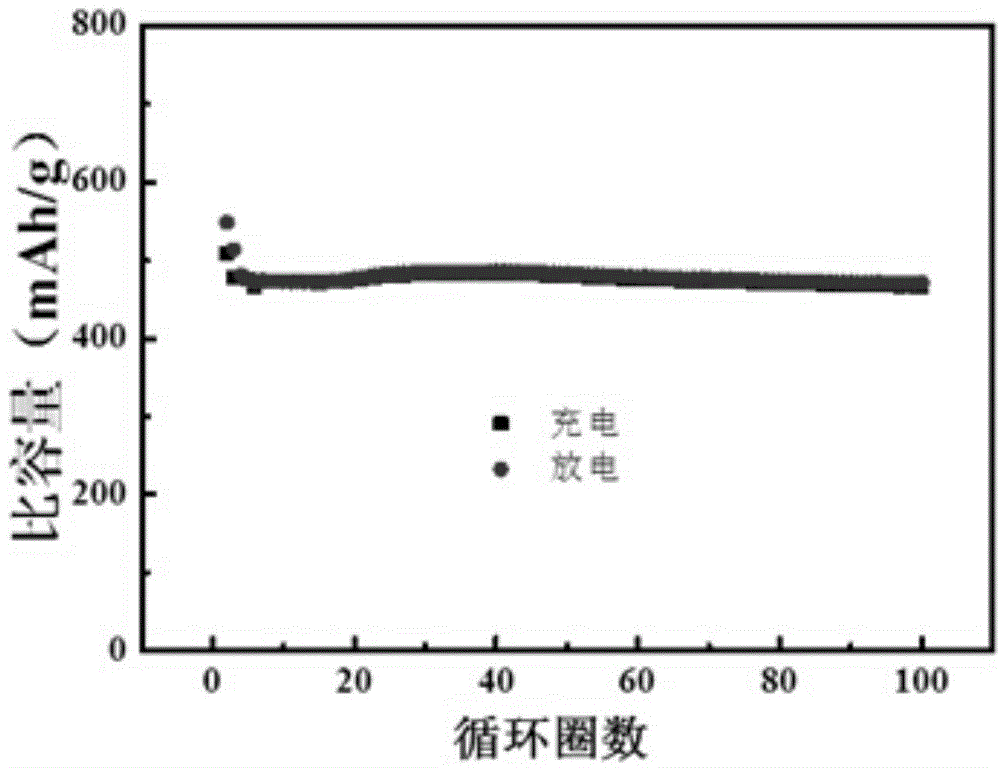

[0040] Prepared by traditional solid-phase mixing method, mix copper powder and sulfur powder with a molar ratio of Cu:S=1:1 evenly, put it into a sealed glass tube with an inert atmosphere, and react in a muffle furnace at 400°C for 3h , and the material was taken out when the temperature was naturally cooled to room temperature. The electrochemical test is the same as in Example 1. The electrode material prepared by the method in Example 1 is charged and discharged at a current density of 100mA / g. The initial discharge capacity is 500mAh / g. After 100 cycles, the reversible capacity is maintained at 372mA / g. The rate is 74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com