Metallothionein (MT) extraction and separation process for marine biological source efficient heavy metal removal agent

A technology of metallothionein and marine organisms, applied in the field of marine biological source metallothionein, can solve the problems of waste of resources, pollution of the environment, etc., and achieve the effect of reducing the impact of safety, reducing industrial costs, and reducing the removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

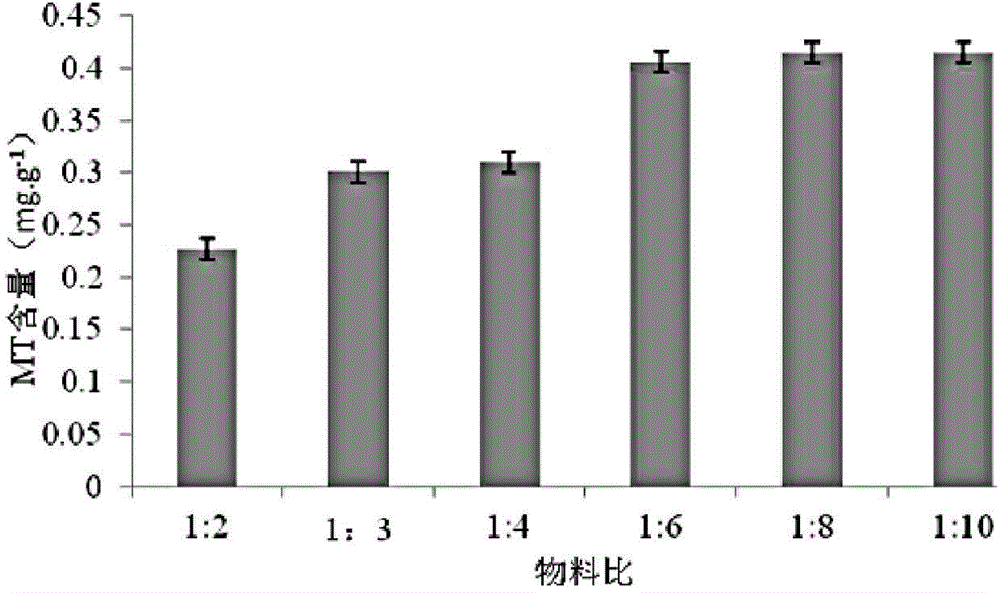

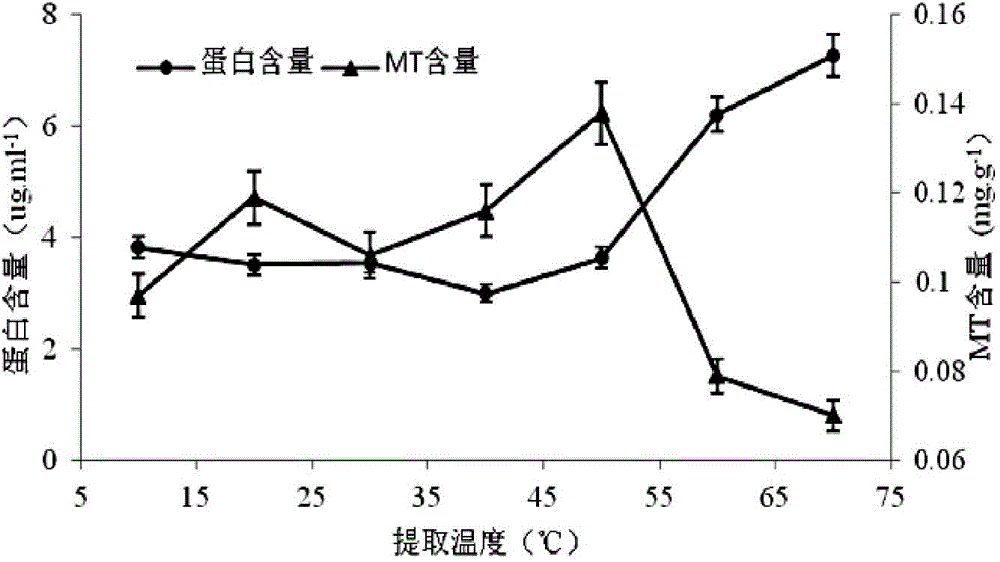

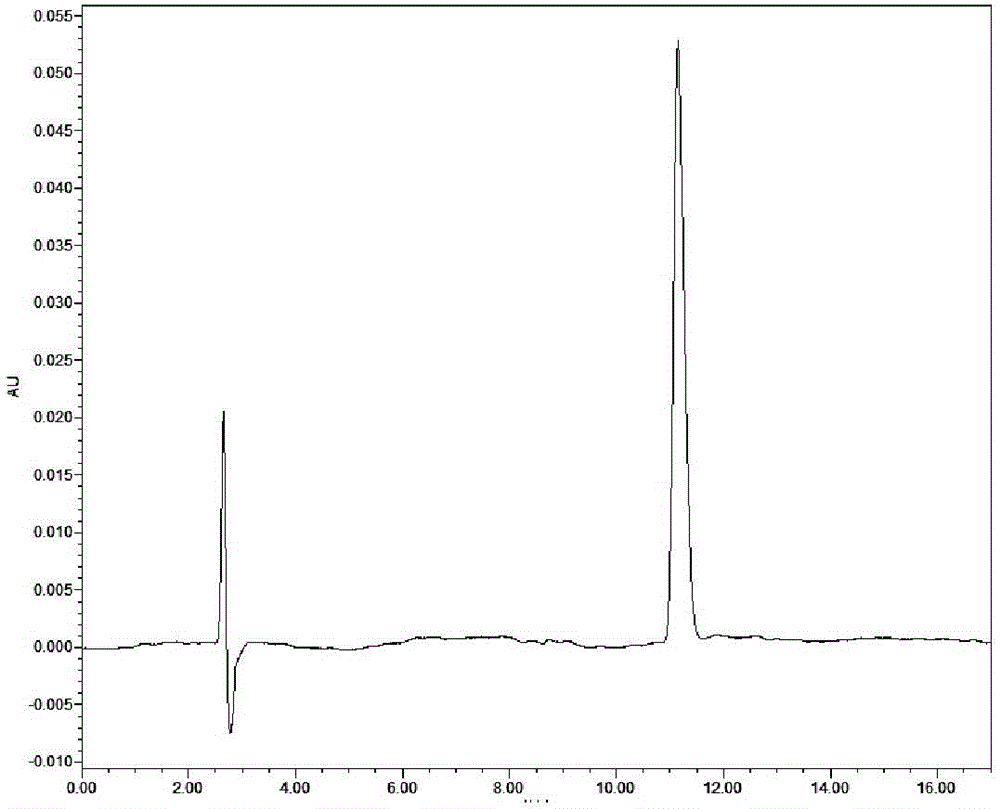

[0034] Quickly homogenate the fish viscera, a by-product of marine aquatic product processing, weigh 50Kg of the homogenized raw material, put in 350L 0.25 mol / L Tris-HCL buffer solution, and oxidize with hydrochloric acid and hydrogen Sodium controls the pH of the extract to 8.5, and stirs and extracts at 45°C for 2 hours. The extract is heated at 60°C for 60 minutes to remove impurities, and after cooling, the sediment is removed by a continuous flow centrifuge. The centrifugate is first filtered through a plate-and-frame microfiltration membrane Clarify and remove macromolecular compounds at the same time, and then separate, purify and concentrate through ultrafiltration, nanofiltration and other multi-membrane integrated purification systems to obtain crude MT. The crude MT was separated and purified by Sephadex G-50 and DEAE-FF chromatography, and then dried to obtain high-purity marine biological source MT products.

Embodiment 2

[0036]Quickly homogenate the fish viscera, a by-product of marine aquatic product processing, weigh 20Kg of the homogenized raw material, and put in 200L 0.1 mol / L phosphate buffer solution according to the mass volume ratio of the raw material and buffer solution at 1:10, and control it with hydrochloric acid and sodium hydroxide The pH of the extract was 8.0, stirred and extracted at 25°C for 4 hours, the extract was heated at 80°C for 5 minutes to remove impurities, and after cooling, the sediment was removed by a continuous flow centrifuge. The centrifugate was first filtered and clarified through a 0.1um ceramic mold, and Remove macromolecular compounds, and then separate, purify and concentrate with molecular weight cut-offs of 500KDa, 10KDa and 500Da to obtain crude products. The crude MT was separated and purified by Sephadex G-50 and DEAE-FF chromatography, the MT fraction was collected, and then dried to obtain high-purity marine biological source MT products.

Embodiment 3

[0038] Quickly homogenate the fish viscera, a by-product of marine aquatic product processing, weigh 50Kg of the homogenized raw material, put in 250L 0.3mol / L sodium chloride solution according to the mass volume ratio of the raw material and the buffer solution as 1:5, and use hydrochloric acid and sodium hydroxide Control the pH of the extract to 8.5, stir and extract at 55°C for 2 hours, heat the extract at 60°C for 30 minutes to remove impurity proteins, and remove the sediment by a continuous flow centrifuge after cooling, the centrifugate is first filtered and clarified through a plate-and-frame microfiltration membrane , and remove macromolecular compounds at the same time, and then separate, purify and concentrate by molecular weight cut-off of 50KDa and 1KDa respectively to obtain crude MT. The crude SOD was separated and purified by sephadex G-100 and ion exchange resin chromatography, the MT fraction was collected, and then dried to obtain high-purity marine biologi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com