Preparation method of layered Li4Ti5O12@graphene composite lithium ion battery anode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low rate, charge and discharge capacity, and limitation, and achieve improved electrical conductivity, high specific surface area, and increased charging capacity. Effects of discharge capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A layered Li 4 Ti 5 o 12 Preparation of graphene composite lithium-ion battery anode materials:

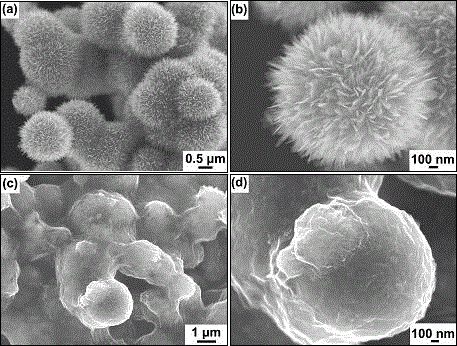

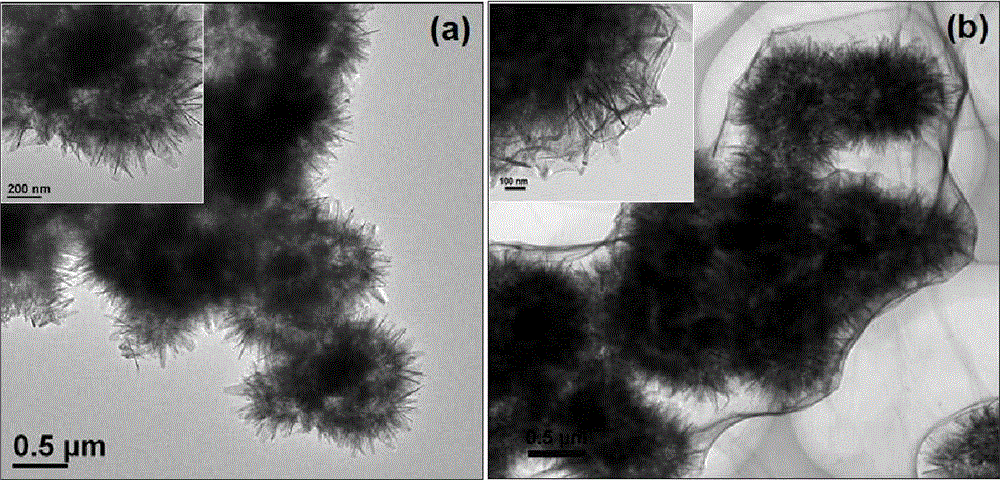

[0022] (1) Dandelion shape 4 Ti 5 o 12 Microsphere synthesis

[0023] Dandelion shape 4 Ti 5 o 12 The microspheres were synthesized by a new and improved hydrothermal method. The preparation steps are as follows: First, 0.672 g LiOH·H 2O was dissolved in 40 mL of deionized water, then 2 mL of 30% hydrogen peroxide was added, and 1.360 g of tetrabutyl titanate (TBT) was also added, and the process was kept under vigorous stirring; after 30 min, the prepared The mixed solution was transferred to a clean stainless steel autoclave lined with polytetrafluoroethylene, and kept at 150 °C for 6 h; after natural cooling to room temperature, the milky white precipitate was collected by centrifugation, and washed with deionized water and ethanol for several times, and then dried at 80°C for 5 h; finally, the obtained samples were annealed in air atmosphere at 500°C ...

Embodiment 2

[0030] A layered Li 4 Ti 5 o 12 Preparation of graphene composite lithium-ion battery anode materials:

[0031] (1) Dandelion shape 4 Ti 5 o 12 Microsphere synthesis

[0032] Dandelion shape 4 Ti 5 o 12 The microspheres were synthesized by a new and improved hydrothermal method. The preparation steps are as follows: First, 0.689 g LiOH·H 2 O was dissolved in 40 mL of deionized water, then 2.1 mL of 30% hydrogen peroxide was added, and 1.398 g of tetrabutyl titanate (TBT) was also added, and the process was kept under vigorous stirring; after 30 min, the prepared The mixed solution was transferred to a clean stainless steel autoclave lined with polytetrafluoroethylene, and kept at 150 °C for 6 h; after natural cooling to room temperature, the milky white precipitate was collected by centrifugation and washed with deionized water and ethanol several times, and then dried at 75°C for 6 h; finally, the obtained sample was annealed in air atmosphere at 500°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com