Preparation method of high purity capsaicin monomer

A high-purity technology for capsaicin, applied in the separation and purification of capsaicin, the purification of natural active ingredients, and the field of dihydrocapsaicin monomer, which can solve the problems of long time consumption, low purity, and large solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Measure 100mL of capsicum essential oil into a beaker, add 300mL of 75% ethanol, stir and extract at 30°C for 12h, let it stand for 1h, filter, concentrate the filtrate under reduced pressure to remove alcohol, put the concentrate directly on the column for adsorption, and wash away impurities with 15% ethanol , Then elute with 70% ethanol, collect eluate, concentrate under reduced pressure, dry to obtain 22.73g capsaicin total alkaloids.

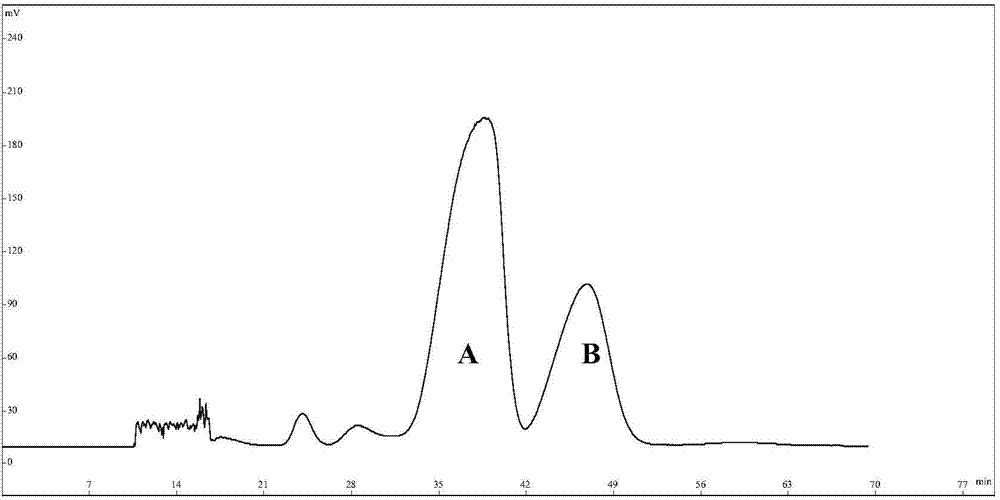

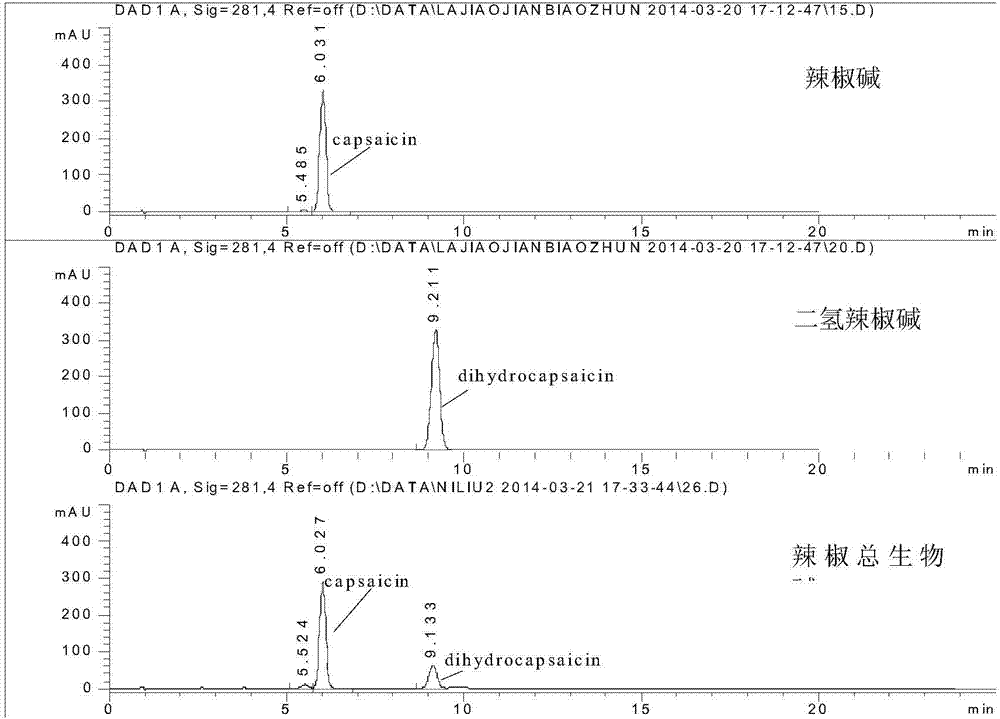

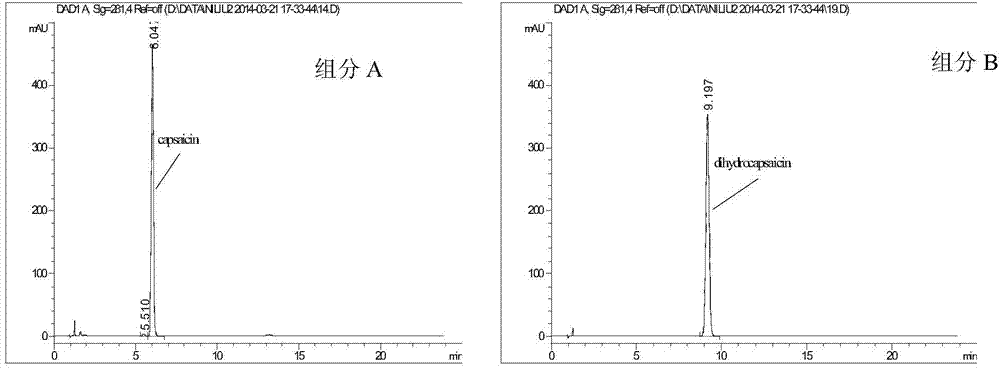

[0031] (2) Use Shanghai Tongtian TBE-300C semi-preparative high-speed countercurrent chromatography system for separation, the volume of the column is 300mL, the solvent system is petroleum ether-ethyl acetate-ethanol-water 5:5:5:5, column temperature: 25°C. The preparation of capsaicin and dihydrocapsaicin is carried out in two steps: 1. sherwood oil-ethyl acetate-ethanol-water with a volume ratio of 5:5:5:5 is miscible in a separatory funnel, shake up and then separate layer. Get the upper layer solution (upper phase) as the ...

Embodiment 2

[0033] Shanghai Tongtian TBE-300C semi-preparative high-speed countercurrent chromatography system was used for separation. The column volume was 300mL, the solvent system was n-hexane-ethyl acetate-methanol-water 5:5:5:5, and the column temperature was 25°C. The preparation of capsaicin and dihydrocapsaicin is carried out in two steps: 1. Mix n-hexane-ethyl acetate-methanol-water with a volume ratio of 5:5:5:5 in a separatory funnel, shake it up and then divide layer. Get the upper layer solution (upper phase) as the stationary phase, and the lower layer solution (lower phase) as the mobile phase. Before sample injection, fill the entire column with the stationary phase, adjust the speed of the main engine to 890rpm, and pump the mobile phase into the column at a flow rate of 7.0mL / min to establish a dynamic balance of the entire system. Mixed solution 4mL dissolves 300mg of total alkaloids of capsaicin obtained in Example 1 and is injected by the injection valve, and then r...

Embodiment 3

[0035] (1) Measure 200g of chili powder into a beaker, add 400mL of 75% ethanol, stir and extract at 50°C for 12h, let it stand for 1h, filter, concentrate the filtrate under reduced pressure to remove alcohol, put the concentrate directly on the column for adsorption, and wash away impurities with 15% ethanol , Then elute with 70% ethanol, collect eluate, concentrate under reduced pressure, dry to obtain 6.2g capsaicin total alkaloids.

[0036] (2) Use Shanghai Tongtian TBE-300C semi-preparative high-speed countercurrent chromatography system for separation, the volume of the column is 300mL, the solvent system is n-hexane-ethyl acetate-methanol-0.4mM hydrochloric acid 5:5:5:5, the column Temperature: 35°C. The preparation of capsaicin and dihydrocapsaicin is carried out in two steps: 1. the n-hexane-ethyl acetate-methanol-0.4mM hydrochloric acid miscibility of 5:5:5:5 by volume ratio is mixed in the separatory funnel, after shaking up Still layering. Get the upper layer so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com