Calcium feldspar porous ceramics with controllable structure and adjustable performance and preparation method thereof

A technology of porous ceramics and anorthite, which is applied in the field of anorthite porous ceramics and its preparation, can solve problems such as limiting high-temperature applications, affecting high-temperature performance, and low purity, and achieves high green strength, high uniformity, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In a specific example of the preparation method of anorthite porous ceramics of the present invention, the raw material used is γ-Al 2 o 3 (9um), CaCO 3 (0.8um) and SiO 2 (4um), the purity is analytically pure, and the molar ratio of ingredients is 1:1:2. The detailed preparation steps are as follows:

[0031] 1) Prepare the premix;

[0032] The solid content of the ceramic slurry is 12vol.%. Weigh 88g of deionized water into the beaker, weigh 8.8g of acrylamide powder and add it to the above beaker, weigh 0.88g of N,N'-methylenebisacrylamide and add it to the above beaker, and weigh 0.17g of ammonium polyacrylate Place in the above beaker. Then use JJ-1 type precision booster electric stirrer to mechanically stir to prepare the premix, the stirring speed is 2000 rpm, and the stirring time is about 30 minutes.

[0033] 2) preparing a homogeneously mixed ceramic slurry;

[0034] First, pour the above-mentioned homogeneously mixed premix into a ball mill jar equip...

example 1

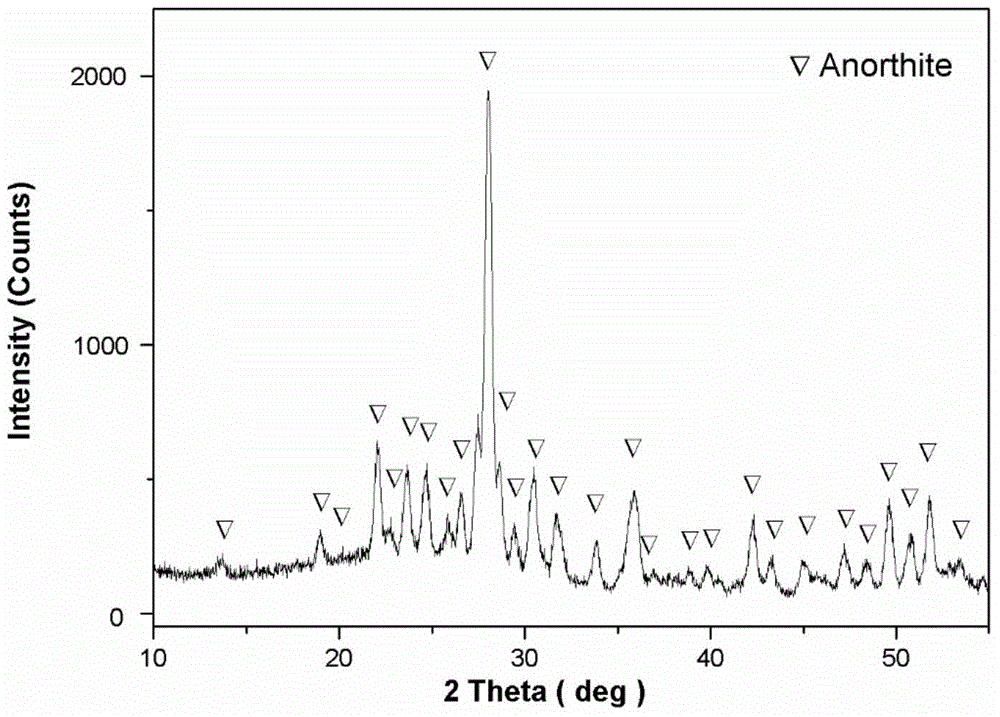

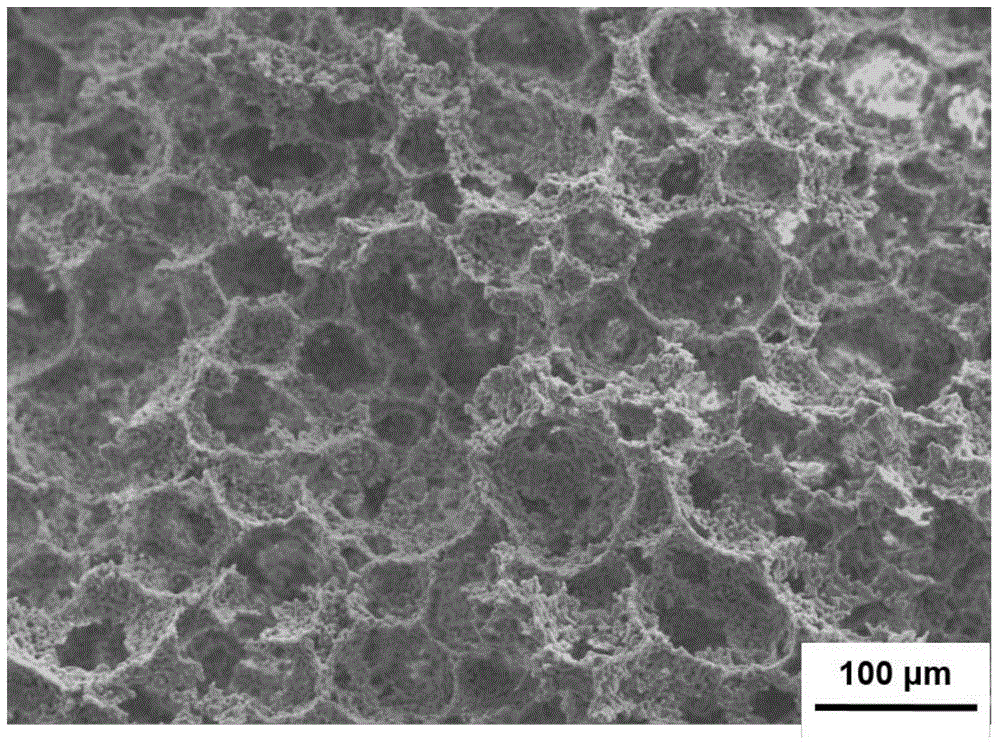

[0043] The purity of the anorthite porous ceramics finally prepared by example 1 is higher, and only the diffraction peak of anorthite can be observed in the XRD diffraction pattern, and the diffraction pattern is as shown in accompanying drawing 1 (a); Prepare the pores of anorthite porous ceramics It is a multi-level structure, and submicron pores are distributed on the spherical large pore wall. The typical microstructure is shown in Figure 2 (a); the physical properties of the prepared anorthite porous ceramics are as follows: the apparent porosity is 91.4± 0.5%, bulk density 0.24±0.01g / cm 3 , Room temperature vacuum thermal conductivity 0.018±0.005W / m·K.

Embodiment 2

[0045] The raw material used is γ-Al 2 o 3 (9um), CaCO 3 (0.8um) and SiO 2 (4um), the purity is analytically pure, and the molar ratio of ingredients is 1:1:2. The detailed preparation steps are as follows:

[0046] 1) Prepare the premix;

[0047] The solid content of the ceramic slurry is 12vol.%. Weigh 44g of deionized water into the beaker, weigh 4.4g of acrylamide powder into the above beaker, weigh 0.44g of N,N'-methylenebisacrylamide into the above beaker, and weigh 0.085g of ammonium polyacrylate Place in the above beaker. Then use JJ-1 type precision booster electric stirrer to mechanically stir to prepare the premix, the stirring speed is 2000 rpm, and the stirring time is about 30 minutes.

[0048] 2) preparing a homogeneously mixed ceramic slurry;

[0049] First, pour the above-mentioned homogeneously mixed premix into a ball mill jar equipped with a certain amount of agate balls; then weigh 6.23g SiO 2 , 5.285gγ-Al 2 o 3 and 5.185g CaCO 3 Pour into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solid content | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com