Preparation method of low-cost hollow spherical YSZ powder for plasma spraying

A low-cost, plasma technology, applied in the field of preparation of low-cost hollow spherical YSZ powder for ion spraying, can solve the problems of high equipment cost, content, and influence on the service life of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

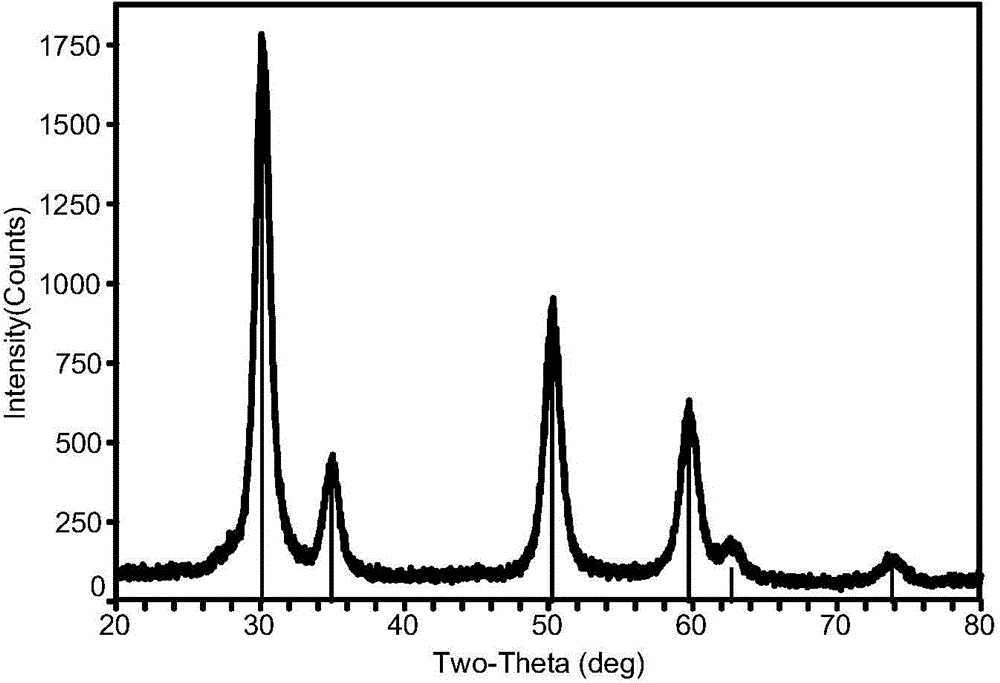

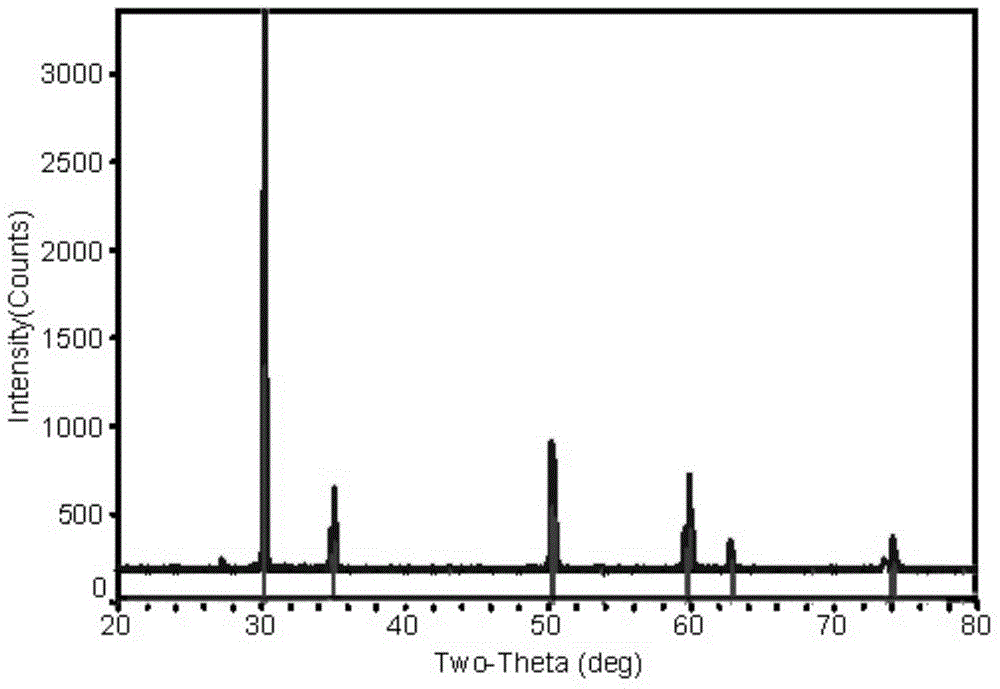

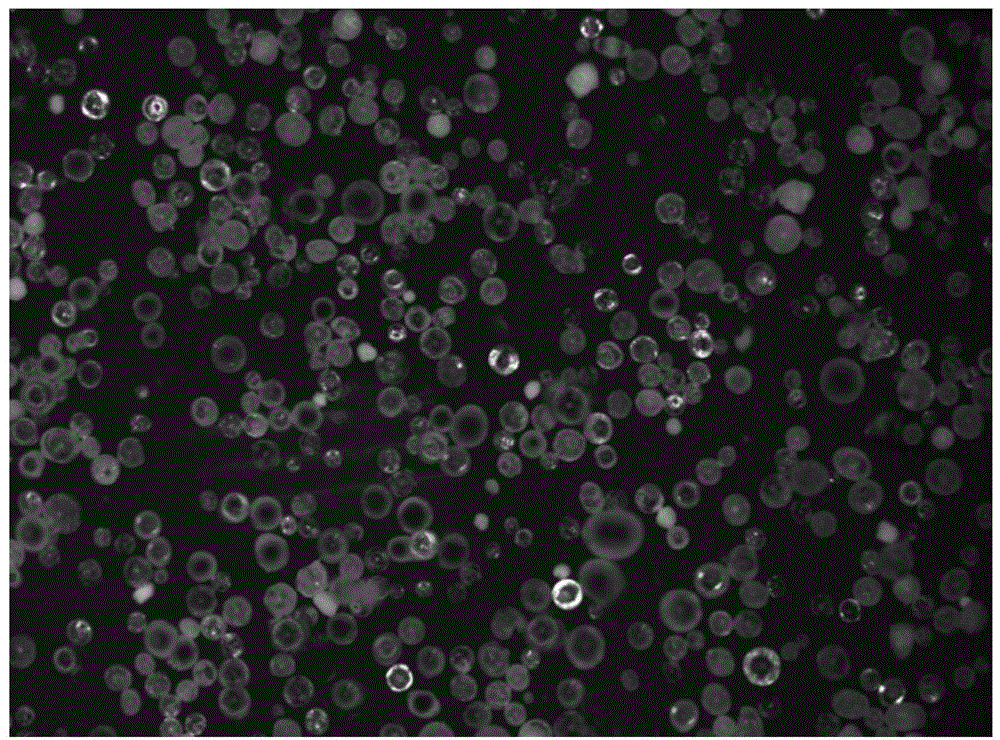

Image

Examples

Embodiment 1

[0029] The preparation method of the low-cost hollow spherical YSZ powder for plasma spraying in this embodiment comprises the following steps:

[0030] Step 1, mix the yttrium salt and the zirconium salt according to the molar ratio of Y:(Y+Zr)=8:100, and then add deionized water and stir until the yttrium salt and the zirconium salt are completely dissolved to obtain a mixed solution; the mixed solution The sum of the molar concentration of the yttrium salt and the molar concentration of the zirconium salt is 0.5mol / L; the yttrium salt is a water-soluble trivalent yttrium salt, preferably yttrium chloride or yttrium nitrate; the zirconium salt is A water-soluble tetravalent zirconium salt is preferably zirconium tetrachloride, zirconium nitrate or zirconium oxychloride; the yttrium salt used in this embodiment is yttrium chloride, and the zirconium salt used is zirconium tetrachloride;

[0031] Step 2, using ammonia water with a mass percentage concentration of 28% as a prec...

Embodiment 2

[0038] The preparation method of the low-cost hollow spherical YSZ powder for plasma spraying in this embodiment comprises the following steps:

[0039] Step 1, mix the yttrium salt and the zirconium salt according to the molar ratio of Y:(Y+Zr)=7.8:100, and then add deionized water and stir until the yttrium salt and the zirconium salt are completely dissolved to obtain a mixed solution; the mixed solution The sum of the molar concentration of the yttrium salt and the molar concentration of the zirconium salt is 0.8mol / L; the yttrium salt is a water-soluble trivalent yttrium salt, preferably yttrium chloride or yttrium nitrate; the zirconium salt is A water-soluble tetravalent zirconium salt is preferably zirconium tetrachloride, zirconium nitrate or zirconium oxychloride; the yttrium salt used in this embodiment is yttrium nitrate, and the zirconium salt used is zirconium oxychloride;

[0040] Step 2, using ammonia water with a mass percentage concentration of 30% as a preci...

Embodiment 3

[0047] The preparation method of the low-cost hollow spherical YSZ powder for plasma spraying in this embodiment comprises the following steps:

[0048] Step 1, mix the yttrium salt and the zirconium salt according to the molar ratio of Y:(Y+Zr)=7.5:100, and then add deionized water and stir until the yttrium salt and the zirconium salt are completely dissolved to obtain a mixed solution; the mixed solution The sum of the molar concentration of the yttrium salt and the molar concentration of the zirconium salt is 0.1mol / L; the yttrium salt is a water-soluble trivalent yttrium salt, preferably yttrium chloride or yttrium nitrate; the zirconium salt is A water-soluble tetravalent zirconium salt, preferably zirconium tetrachloride, zirconium nitrate or zirconium oxychloride; the yttrium salt used in this embodiment is yttrium chloride, and the zirconium salt used is zirconium nitrate;

[0049] Step 2, using ammonia water with a mass percentage concentration of 25% as a precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com