The method for preparing carboxymethyl hydroxypropyl guar gum powder by one-step method of guar gum sheet

A technology of carboxymethyl hydroxypropyl guar powder and guar film, which is applied in the field of preparation of carboxymethyl hydroxypropyl guar gum, can solve the problems of long reaction time and high cost, and achieves short reaction time and easy operation. Simple, low water-insoluble content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

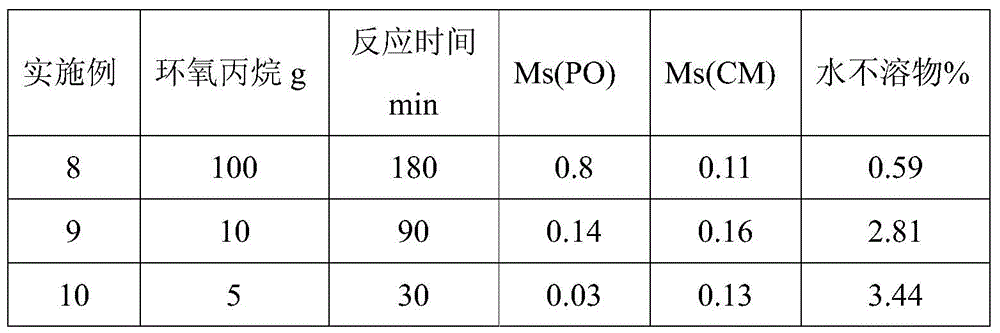

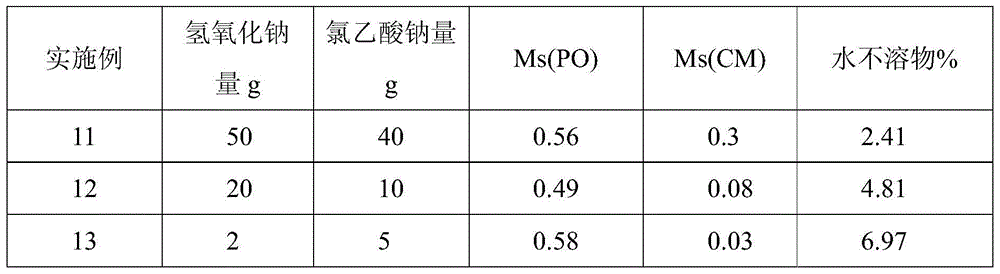

Examples

Embodiment 1

[0023] The method for preparing carboxymethyl hydroxypropyl guar powder by one-step guar film, the steps are as follows:

[0024] To a multi-necked flask with mechanical stirring, a thermometer, a dropping funnel and a reflux condenser, add 100 g of guar chips, 200 g of isopropanol, and 100 g of water; the temperature is raised to 45°C. 40 g of a 30 wt % aqueous sodium hydroxide solution was added, and the basification reaction was maintained at 45° C. for 30 min. At the same time, 30 g of sodium chloroacetate and 40 g of propylene oxide were added to the system, and the reaction was performed for 120 min after the addition. After the reaction, the temperature was lowered to 30° C., washed with 80% isopropanol aqueous solution, pulverized and dried to obtain the finished product.

[0025] The molar substitution degree of hydroxypropyl of the obtained product is 0.54, and the molar substitution degree of hydroxypropyl is abbreviated as Ms(PO) in the following examples; the mol...

Embodiment 2

[0027] The method for preparing carboxymethyl hydroxypropyl guar powder by one-step guar film, the steps are as follows:

[0028] To a multi-necked flask with mechanical stirring, a thermometer, a dropping funnel and a reflux condenser, add 100 g of guar chips, 200 g of isopropanol, and 100 g of water; the temperature is raised to 45°C. 60 g of 30 wt % aqueous sodium hydroxide solution was added, and the reaction was maintained at 45° C. for 30 min for alkalization. At the same time, 30 g of sodium chloroacetate and 30 g of 1,2-epoxybutane were added to the system, and the reaction was performed for 120 min after the addition. After the reaction, the temperature was lowered to 30° C., washed with 80% isopropanol aqueous solution, pulverized and dried to obtain the finished product.

[0029] The molar substitution degree of hydroxybutyl group is 0.41; the molar substitution degree of carboxymethyl group is 0.14; the water insoluble matter is 1.84%.

Embodiment 3

[0031] The method for preparing carboxymethyl hydroxypropyl guar powder by one-step guar film, the steps are as follows:

[0032] To a multi-necked flask with mechanical stirring, a thermometer, a dropping funnel and a reflux condenser, add 100 g of guar chips, 200 g of isopropanol, and 100 g of water; the temperature is raised to 45°C. 60 g of 30 wt % aqueous sodium hydroxide solution was added, and the reaction was maintained at 45° C. for 30 min for alkalization. At the same time, 10 g of chloroacetic acid, 10 g of sodium chloroacetate, and 40 g of propylene oxide were added to the system, and the reaction was performed for 120 min after the addition. After the reaction, the temperature was lowered to 30° C., washed with 80% isopropanol aqueous solution, pulverized and dried to obtain the finished product.

[0033] The molar substitution degree of hydroxypropyl group is 0.51, the molar substitution degree of carboxymethyl group is 0.16, and the water insoluble matter is 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com