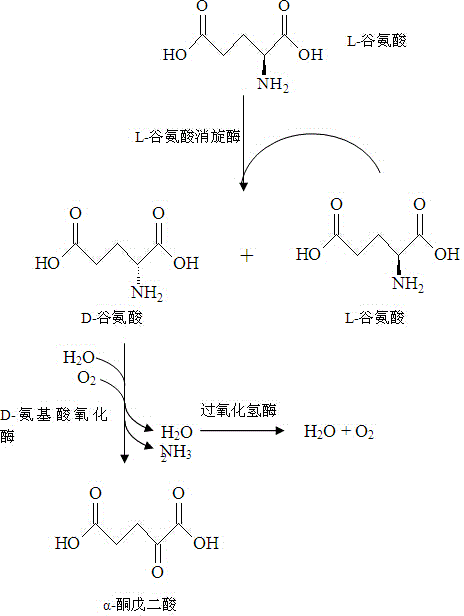

Production method for alpha-ketoglutaric acid

A technology of ketoglutaric acid and production method, applied in the direction of introducing foreign genetic material by using carrier, recombinant DNA technology, fermentation, etc., which can solve the problems of high fermentation cost of L-glutamic acid oxidase, difficulty in separation and purification of fermentation products, etc. , to achieve the effect of easy separation, reduced separation cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Step 1, construction of glutamic acid racemase genetically engineered bacteria

[0058] (1), according to GenBank: AB003685.1 recorded from Bacillus subtilis IFO 3336 encoding glutamic acid racemase glr Gene sequence, plus enzyme cutting sites at both ends Nde I and Bam HI, after the start codon was changed from TTG to ATG, the whole gene synthesis was carried out, and the synthetic glr The specific sequence of the gene is shown as SEQ ID NO: 1;

[0059] (2), the synthesized glr Genetic use Nde I and Bam HI double enzyme digestion, purification for later use;

[0060] (3), extract Escherichia coli expression vector pET24a, use Nde I and Bam HI double enzyme digestion, and purified in the previous step glr The gene fragments were connected and transformed into Escherichia coli DH5α competent cells;

[0061] (4) After picking positive transformants and identifying them by sequencing, the plasmids were extracted to obtain glr Expression vector pET24a-glr;

...

Embodiment 2

[0075] Step 1, construction of glutamic acid racemase genetically engineered bacteria

[0076] (1), according to GenBank: AB003685.1 recorded from Bacillus subtilis IFO 3336 encoding glutamic acid racemase glr Gene sequence, plus enzyme cutting sites at both ends Nde I and Bam HI, after the start codon was changed from TTG to ATG, the whole gene synthesis was carried out, and the synthetic glr The specific sequence of the gene is shown as SEQ ID NO: 1;

[0077] (2), the synthesized glr Genetic use Nde I and Bam HI double enzyme digestion, purification for later use;

[0078] (3), extract Escherichia coli expression vector pET24a, use Nde I and Bam HI double enzyme digestion, and purified in the previous step glr The gene fragments were connected and transformed into Escherichia coli DH5α competent cells;

[0079] (4) After picking positive transformants and identifying them by sequencing, the plasmids were extracted to obtain glr Expression vector pET24a-glr;

...

Embodiment 3

[0093] Step 1, construction of glutamic acid racemase genetically engineered bacteria

[0094] (1), according to GenBank: AB003685.1 recorded from Bacillus subtilis IFO 3336 encoding glutamic acid racemase glr Gene sequence, plus enzyme cutting sites at both ends Nde I and Bam HI, after the start codon was changed from TTG to ATG, the whole gene synthesis was carried out, and the synthetic glr The specific sequence of the gene is shown as SEQ ID NO: 1;

[0095] (2), the synthesized glr Genetic use Nde I and Bam HI double enzyme digestion, purification for later use;

[0096] (3), extract Escherichia coli expression vector pET24a, use Nde I and Bam HI double enzyme digestion, and purified in the previous step glr The gene fragments were connected and transformed into Escherichia coli DH5α competent cells;

[0097] (4) After picking positive transformants and identifying them by sequencing, the plasmids were extracted to obtain glr Expression vector pET24a-glr;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com