Solar photoelectric conversion coating for building and fabrication method for solar photoelectric conversion coating

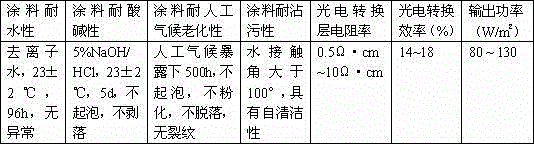

A photoelectric conversion, solar energy technology, applied in conductive coatings, photovoltaic power generation, radiation-absorbing coatings, etc., can solve the problems of poor anti-fouling, poor conductivity, low efficiency, etc., achieve fast curing speed, maintain light transmittance and The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Take 30 parts by weight of phosphorus-doped silicon crystal, 25 parts by weight of epoxy acrylate resin, 4 parts by weight of conductive mica powder, 1 part by weight of 1-chloro-4-hydroxythioxanthone, and 0.2 parts by weight of hydroquinone , 0.2 parts by weight of polyacrylate, 0.2 parts by weight of n-butanol, 0.35 parts by weight of polyoxyethylene alkylphenyl ether, add 25 parts by weight of water, and press the preparation method step a to prepare II:N type semiconductor coatings.

[0037] 2) Get 30 parts by weight of boron-doped silicon crystals, 25 parts by weight of epoxy acrylate resin, 4 parts by weight of conductive mica powder, 1 part by weight of 1-chloro-4-hydroxythioxanthone, 0.2 parts by weight of hydroquinone , 0.2 parts by weight of polyacrylate, 0.2 parts by weight of n-butanol, 0.35 parts by weight of polyoxyethylene alkylphenyl ether, add 25 parts by weight of water, according to the preparation method step b, to obtain III: P type semiconducto...

Embodiment 2

[0043] 1) Take 35 parts by weight of gallium arsenide doped with selenium, 30 parts by weight of polyurethane acrylate resin, 5 parts by weight of conductive titanium dioxide, 1.5 parts by weight of 2-hydroxythioxanthone, 0.2 parts by weight of p-benzophenone, and 0.2 parts by weight of organic Silicone resin, 0.2 parts by weight of n-butanol, 0.4 parts by weight of sodium polymethacrylate, and 20 parts by weight of water are added, and according to step a of the preparation method, a II:N type semiconductor coating with uniformly dispersed components is prepared.

[0044] 2) Take 35 parts by weight of zinc-doped gallium arsenide, 30 parts by weight of polyurethane acrylate resin, 5 parts by weight of conductive titanium dioxide, 1.5 parts by weight of 2-hydroxythioxanthone, 0.2 parts by weight of p-benzophenone, and 0.2 parts by weight of organic Silicone resin, 0.2 parts by weight of n-butanol, 0.4 parts by weight of sodium polymethacrylate, and 30 parts by weight of water ar...

Embodiment 3

[0050] 1) Take 40 parts by weight of gallium arsenide doped with selenium, 35 parts by weight of polyurethane acrylate resin, 6 parts by weight of conductive titanium dioxide, 1.5 parts by weight of 1-chloro-4-hydroxythioxanthone, 0.2 parts by weight of p-benzophenone, 0.2 parts by weight of silicone resin, 0.2 parts by weight of tributyl phosphate, 0.5 parts by weight of sodium polymethacrylate, adding 30 parts by weight of water, according to step a of the preparation method, to prepare a II: N-type semiconductor coating with uniform dispersion of components .

[0051] 2) Take 40 parts by weight of zinc-doped gallium arsenide, 35 parts by weight of polyurethane acrylate resin, 6 parts by weight of conductive titanium dioxide, 1.5 parts by weight of 1-chloro-4-hydroxythioxanthone, 0.2 parts by weight of p-benzophenone, 0.2 parts by weight of silicone resin, 0.2 parts by weight of tributyl phosphate, 0.5 parts by weight of sodium polymethacrylate, and 30 parts by weight of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com