Method for extracting V2O5 and carbon from low-carbon stone coal mine

A technology for vanadium pentoxide and stone coal mine, which is applied in the field of vanadium pentoxide and carbon extraction, can solve problems such as high cost and waste of resources, achieve full utilization of mineral resources, protect the natural environment, and realize three-dimensional development and overall governance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

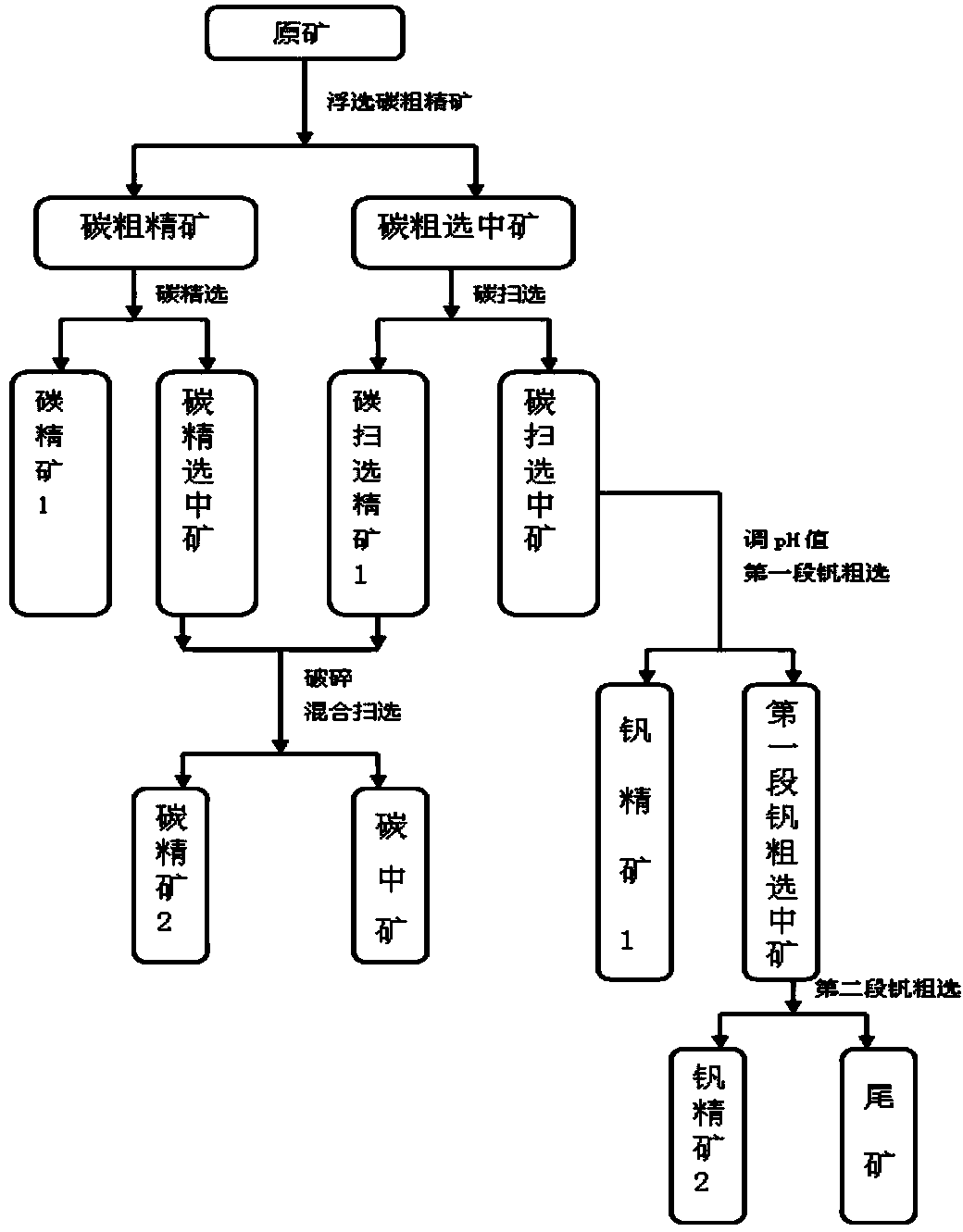

Image

Examples

Embodiment 1

[0051] Taking a stone coal vanadium mine in Shaanxi as the original ore, the grade of V2O5 is 0.65%, and the mass content of carbon is 14.4%.

[0052] Step 1 Mixing

[0053] Crushing the raw ore with a particle size of less than 3mm until the particles with a fineness of -0.074mm account for 38% of the total mass of the raw ore, adding water to adjust the slurry to obtain a slurry with a concentration of 25% by mass of the raw ore;

[0054] Step 2 Flotation to obtain carbon rough concentrate

[0055] Add water glass as a dispersant to the slurry obtained in step 1, stir evenly to fully disperse the mineral particles in the slurry, then add carbon collectors and foaming agents, and carry out carbon roughing to obtain carbon rough concentrate and carbon rough Select ore; the dispersant, carbon collector and foaming agent are added to the slurry in the ratio of 800g dispersant, 1000g carbon collector, and 80g foaming agent per ton of raw ore; the carbon collector is made of kero...

Embodiment 2

[0072] Taking a stone coal vanadium mine in Xinjiang as the original ore, its average V2O5 content is 0.88%, and its carbon content is 13.2%.

[0073] Step 1 Mixing

[0074] Crushing the raw ore with a particle size of less than 3mm until the particles with a fineness of -0.074mm account for 40% of the total mass of the raw ore, adding water to adjust the slurry to obtain a slurry with a concentration of 33% of the mass of the raw ore;

[0075] Step 2 Flotation to obtain carbon rough concentrate

[0076] Add a dispersant (composed of sodium hexametaphosphate and sodium fluorosilicate in a mass ratio of 1:1) to the slurry obtained in step 1, stir evenly to fully disperse the mineral particles in the slurry, then add carbon collector and Foaming agent, carry out carbon coarse separation, obtain carbon rough concentrate and carbon rough ore separation; Described dispersant, carbon collector and foaming agent add 850g dispersant, 1200g carbon collector, 80g minimum per ton of raw...

Embodiment 3

[0092] Taking a stone coal vanadium mine in Guizhou as the original ore, its average V2O5 content is 0.72%, and its carbon content is 11.5%.

[0093] Step 1 Mixing

[0094] Crushing the raw ore with a particle size of less than 3mm until the particles with a fineness of -0.074mm account for 35% of the total mass of the raw ore, adding water to adjust the slurry to obtain a slurry with a concentration of 30% of the mass of the raw ore;

[0095] Step 2 Flotation to obtain carbon rough concentrate

[0096] Add a dispersant (composed of sodium hexametaphosphate and sodium fluorosilicate in a mass ratio of 1:1) to the slurry obtained in step 1, stir evenly to fully disperse the mineral particles in the slurry, then add carbon collector and Foaming agent, carry out carbon coarse separation, obtain carbon coarse concentrate and carbon rough ore separation; Described dispersant, carbon collector and foaming agent add 820g dispersant, 1200g carbon collector, 80g min per ton of raw ore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com