Three-dimensional connective porous artificial bone scaffold as well as preparation method and application thereof

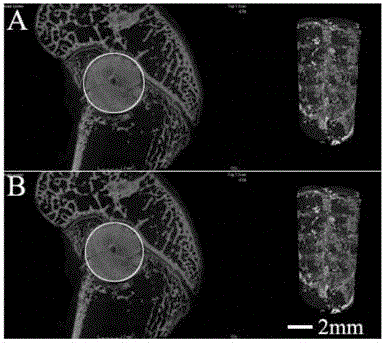

An artificial bone, three-dimensional technology, applied in medical science, prosthesis, etc., can solve the problems of poor mechanical strength, fragility, and poor connectivity of micropores, and achieve the effects of improving mechanical strength, promoting new bone growth, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

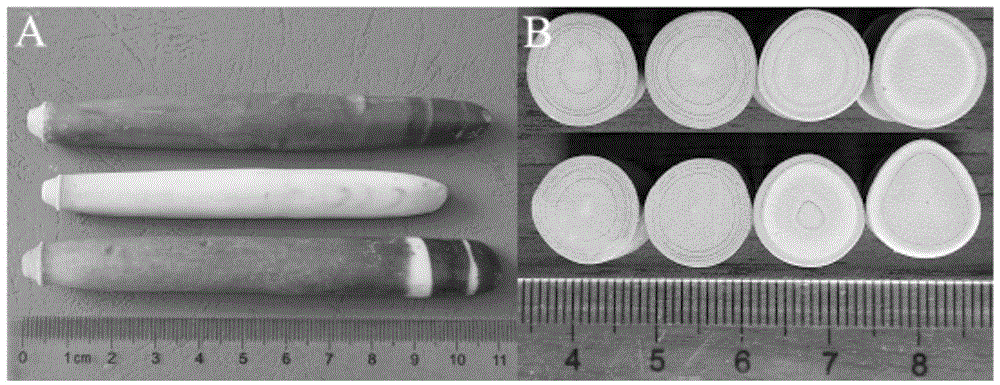

[0031] Raw materials and requirements: slate sea urchin spines and diammonium hydrogen phosphate (analytical grade).

[0032] Mechanical processing: cut sea urchin spines into granular samples ~2mm x2mm x2mm.

[0033] Removal of organic matter and impurities: the sea urchin spine sample was immersed in deionized water and boiled for 30 minutes, and ultrasonically oscillated in 10wt.% NaClO solution for 40 minutes to remove the organic matter and impurities in the sea urchin spine. After taking it out, wash it three times with deionized water and dry it in a vacuum oven at 100°C.

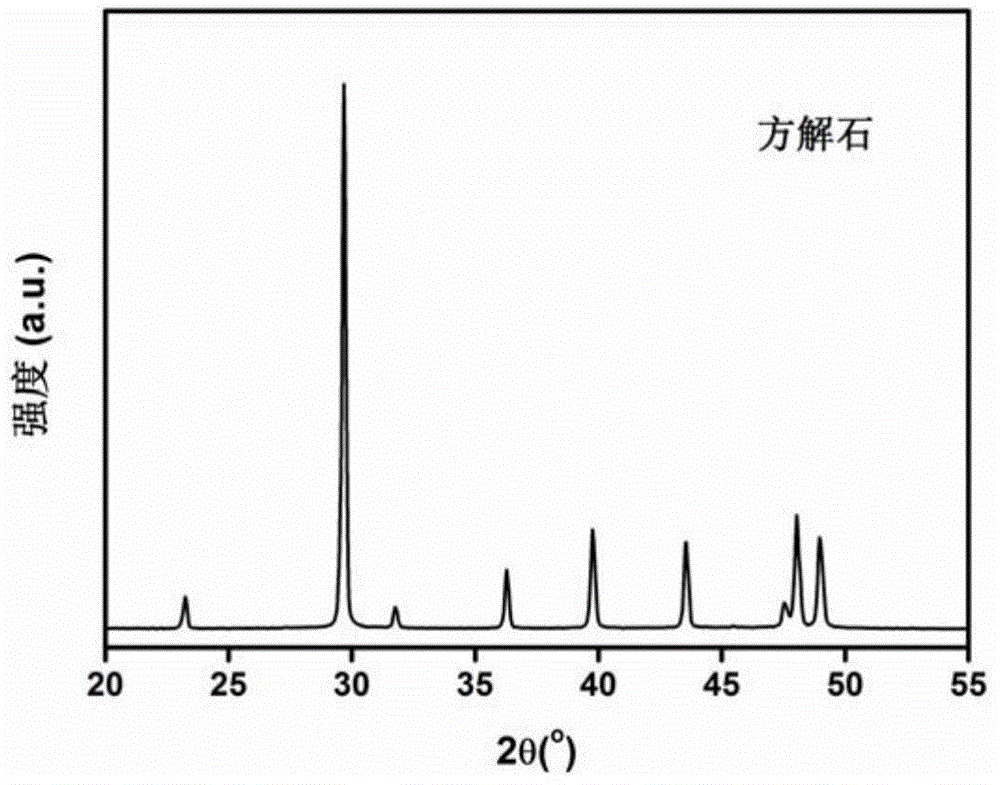

[0034] Hydrothermal reaction: the granular sea urchin spines and (NH 4 ) 2 HPO 4According to the weight ratio of 1:2, it is mixed and placed in a hydrothermal reaction kettle, (NH 4 ) 2 HPO 4 The concentration of the solution is 10wt.%, and the hydrothermal reaction is carried out at 180° C. for 48 hours, and the hydrothermal reaction product is washed and dried to prepare a granular porous Mg-...

Embodiment 2

[0036] Raw materials and requirements: slate sea urchin spines and diammonium hydrogen phosphate (analytical grade).

[0037] Mechanical processing: cut sea urchin spines into granular samples ~2mm x2mm x2mm.

[0038] Removal of organic matter and impurities: the sea urchin spine sample was immersed in deionized water and boiled for 30 minutes, and ultrasonically oscillated in 10wt.% NaClO solution for 40 minutes to remove the organic matter and impurities in the sea urchin spine. After taking it out, wash it three times with deionized water and dry it in a vacuum oven at 100°C.

[0039] Hydrothermal reaction: the granular sea urchin spines and (NH 4 ) 2 HPO 4 According to the weight ratio of 1:2, it is mixed and placed in a hydrothermal reaction kettle, (NH 4 ) 2 HPO 4 The concentration of the solution is 10wt.%, and the hydrothermal reaction is carried out at 160°C for 96 hours. The hydrothermal reaction product is washed and dried to prepare a granular porous Mg-conta...

Embodiment 3

[0041] Raw materials and requirements: slate sea urchin spines and diammonium hydrogen phosphate (analytical grade).

[0042] Mechanical processing: cut sea urchin spines into granular samples ~2mm x2mm x2mm.

[0043] Removal of organic matter and impurities: the sea urchin spine sample was immersed in deionized water and boiled for 30 minutes, and ultrasonically oscillated in 10wt.% NaClO solution for 40 minutes to remove the organic matter and impurities in the sea urchin spine. After taking it out, wash it three times with deionized water and dry it in a vacuum oven at 100°C.

[0044] Hydrothermal reaction: the granular sea urchin spines and (NH 4 ) 2 HPO 4 According to the weight ratio of 1:2, it is mixed and placed in a hydrothermal reaction kettle, (NH 4 ) 2 HPO 4 The concentration of the solution is 10wt.%, and the hydrothermal reaction is carried out at 220°C for 24 hours. The hydrothermal reaction product is washed and dried to prepare a granular porous Mg-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com