Composite electrolyte membrane based on functional polymer and preparation method thereof, and lithium-sulfur secondary cell

A composite electrolyte membrane and polymer technology, applied in the field of rechargeable lithium-sulfur batteries, can solve problems such as the deterioration of cycle performance of lithium-sulfur batteries, and achieve the effects of solving technical problems of performance degradation, suppressing migration loss, and improving cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

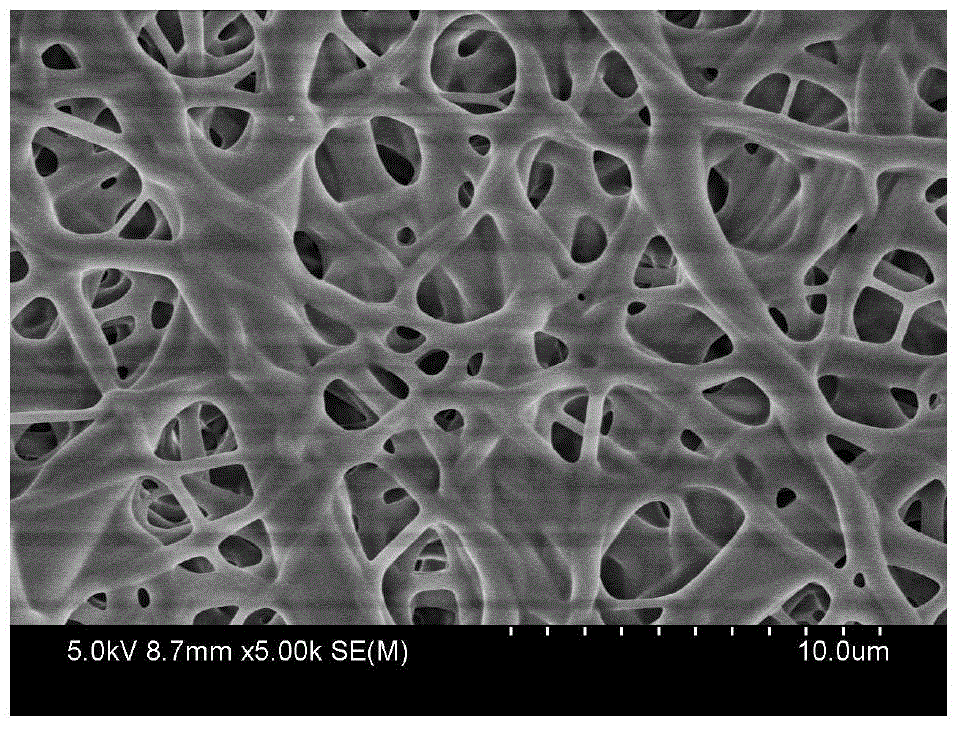

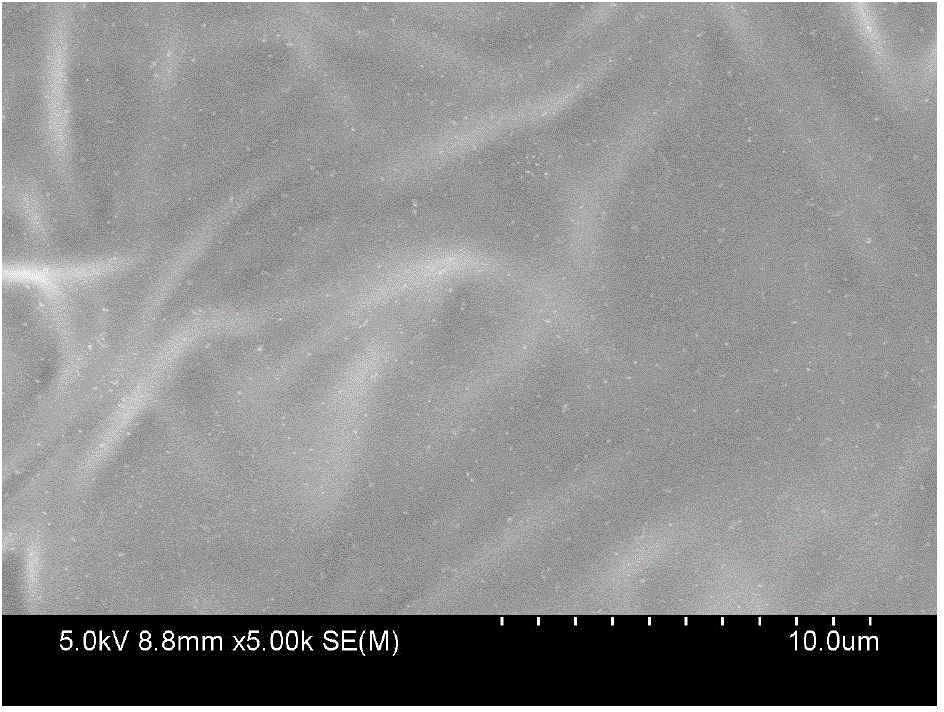

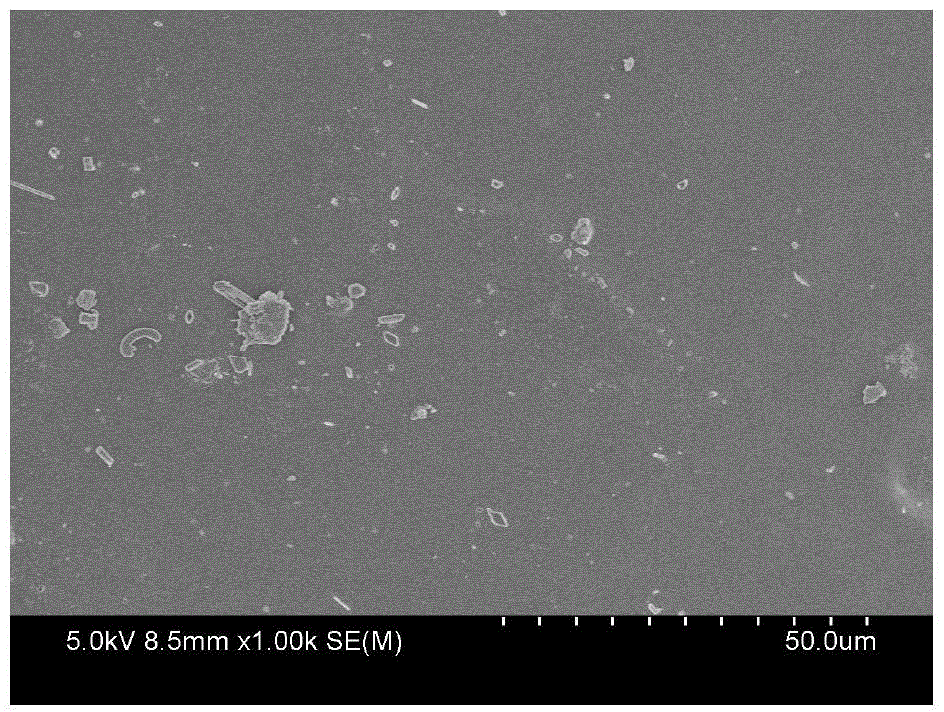

Image

Examples

Embodiment

[0048] A lithium-sulfur secondary battery of the present invention includes a positive electrode, a negative electrode, an electrolyte and an organic electrolyte.

[0049] The electrolyte in this embodiment adopts the special composite electrolyte membrane of the present invention.

[0050] The positive electrode sheet of the positive electrode in this embodiment is generally composed of a current collector that conducts current and a positive active material coated on the current collector, a conductive material, an adhesive, and other additives; the positive active material in this embodiment is selected from a simple substance Sulfur; the conductive material is selected from a carbon-based conductive agent, such as one of conductive carbon black, acetylene black or graphite powder; the adhesive is selected from polyvinylidene fluoride; wherein, the mass percentages of the positive electrode active material, the conductive material, and the adhesive are respectively 70%, 19%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com