Antiviral composition for feed additive, antiviral freeze-dried powder for feed additive and preparation method and use of antiviral freeze-dried powder for feed additive

A feed additive and antiviral technology, applied in the directions of antiviral agents, application, freeze-drying and transportation, etc., can solve the problems of harsher storage conditions of vaccines, stress reaction of livestock and poultry, troublesome operation, etc., so as to prevent and treat viral infections. Efficacy of disease, high antibody titers, cost and labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

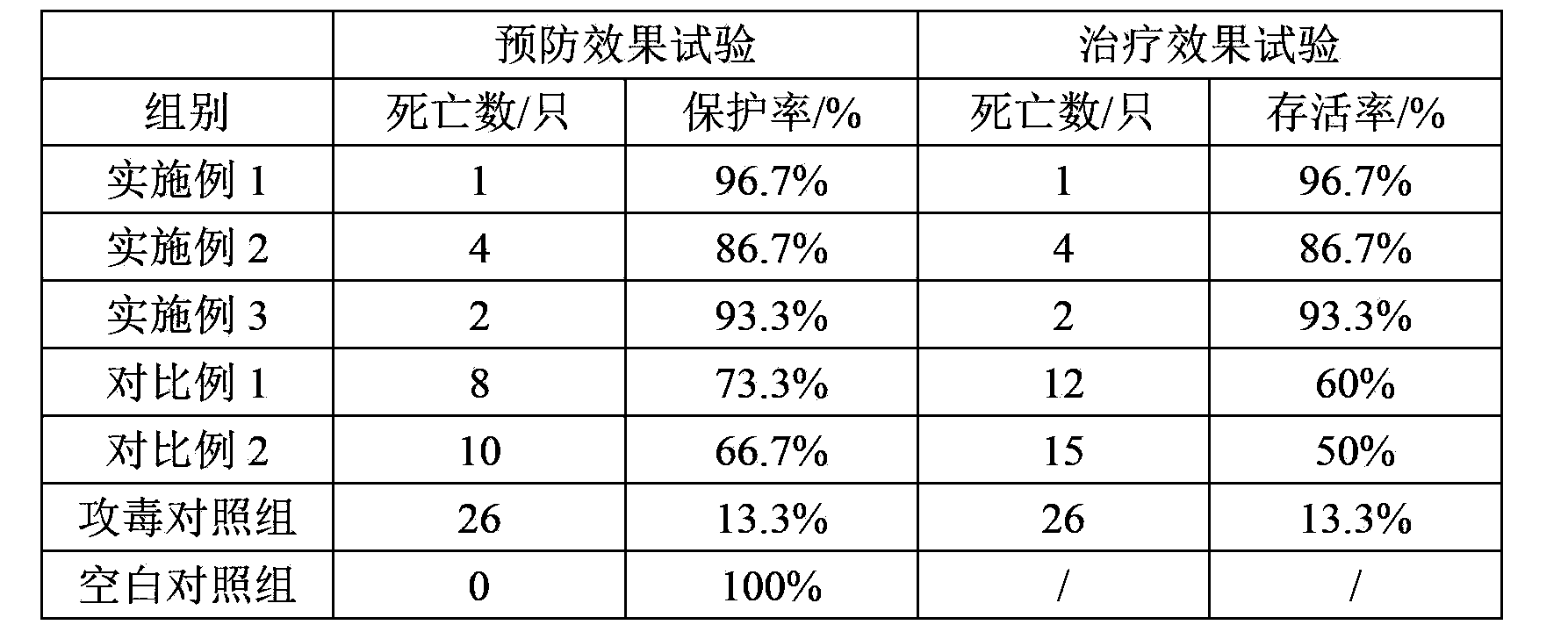

Embodiment 1

[0044] The antiviral composition for feed additive of this embodiment is composed of the following components in parts by weight: 95 parts of anti-canine distemper egg yolk antibody, and 1 part of anti-canine distemper transfer factor.

[0045]The antiviral freeze-dried powder for feed additive of this embodiment is composed of the following components by weight: 95 parts of anti-canine distemper egg yolk antibody, 1 part of anti-canine distemper transfer factor, 0.2 part of formaldehyde, 0.01 part of thimerosal, and 0.05 part of selenium part, 0.5 part of vitamin C, 1 part of polyvinylpyrrolidone, and 0.5 part of glycine.

[0046] The preparation method of antiviral freeze-dried powder for feed additive in the present embodiment, concrete steps are as follows:

[0047] (1) Vaccine preparation from virus strains: the national standard canine distemper virus strains are multiplied and inactivated to prepare emulsifiable concentrate vaccines for use;

[0048] (2) Prepare high-i...

Embodiment 2

[0062] The antiviral composition for feed additive in this embodiment is composed of the following components in parts by weight: 96 parts of anti-canine distemper egg yolk antibody, and 2 parts of anti-canine distemper transfer factor.

[0063] The antiviral freeze-dried powder for feed additive of this embodiment is composed of the following components by weight: 96 parts of anti-canine distemper egg yolk antibody, 2 parts of anti-canine distemper transfer factor, 0.3 part of formaldehyde, 0.02 part of thimerosal, and 0.1 part of selenium 1 part, 1 part of vitamin C, 2 parts of polyvinylpyrrolidone, 0.5 part of glycine.

[0064] The preparation method of antiviral freeze-dried powder for feed additive in the present embodiment, concrete steps are as follows:

[0065] (1) Vaccine preparation from virus strains: the national standard canine distemper virus strains are multiplied and inactivated to prepare emulsifiable concentrate vaccines for use;

[0066] (2) Prepare high-im...

Embodiment 3

[0073] The antiviral composition for feed additive of this embodiment is composed of the following components in parts by weight: 97 parts of anti-canine distemper egg yolk antibody, and 1.5 parts of anti-canine distemper transfer factor.

[0074] The antiviral freeze-dried powder for feed additive of this embodiment is composed of the following components by weight: 97 parts of anti-canine distemper egg yolk antibody, 1.5 parts of anti-canine distemper transfer factor, 0.25 parts of formaldehyde, 0.015 parts of thimerosal, and 0.075 parts of selenium 0.75 parts of vitamin C, 1.5 parts of polyvinylpyrrolidone, and 0.5 parts of glycine.

[0075] The preparation method of antiviral freeze-dried powder for feed additive in the present embodiment, concrete steps are as follows:

[0076] (1) Vaccine preparation from virus strains: the national standard canine distemper virus strains are multiplied and inactivated to prepare emulsifiable concentrate vaccines for use;

[0077] (2) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com