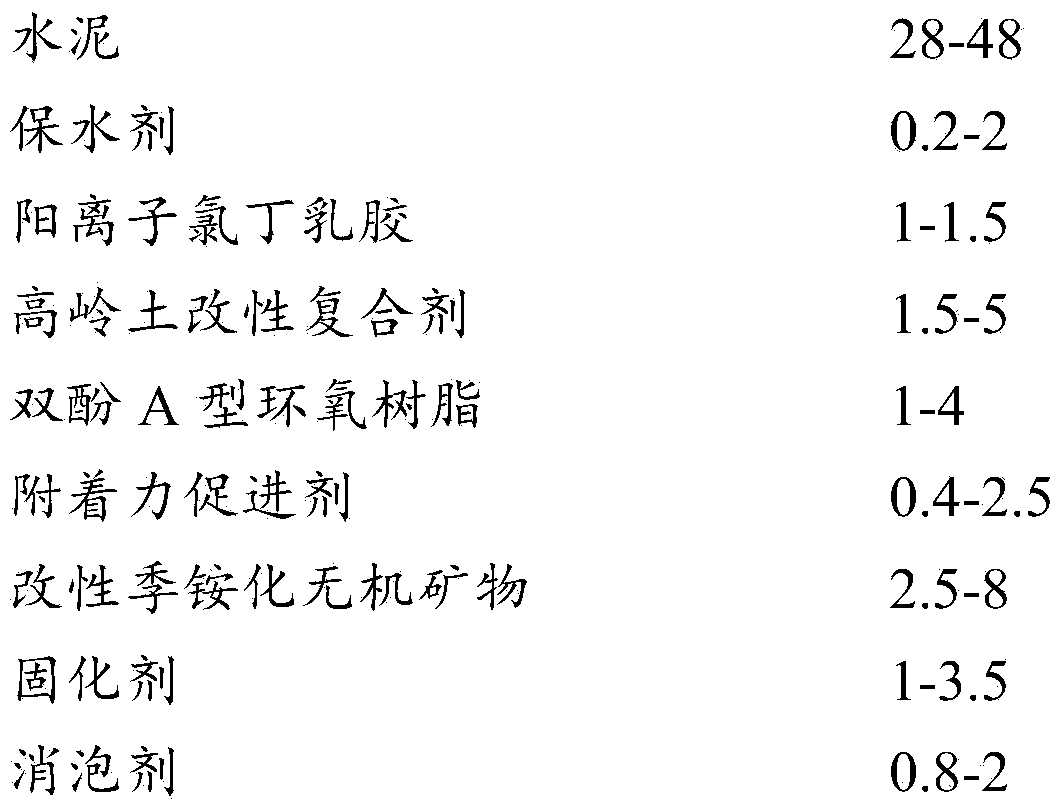

Cement-based finishing slurry and preparation method thereof

A cement-based, slurry technology, applied in the field of building materials, can solve problems such as difficulty in waterproofing, adhesion strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0078] Preparation Example 1: Preparation of Kaolin Modified Compounding Agent

[0079] (1) Add 0.1 mol of acrylic acid (AA), 0.3 mol of vinyl acetate (VAC), 0.3 mol of methacrylic acid (MMA) and 15 mL of water into the reactor, and drop into aqueous sodium hydroxide solution, the aqueous solution 0.07 mol of sodium hydroxide, stirred for 5 min, and mixed uniformly to obtain a mixed solution;

[0080] (2) Add 6 g of kaolin, 30 mL of white kerosene and 3.5 mmol of N,N-methylenebisacrylamide to the mixed solution obtained in step (1), feed nitrogen, and stir for 15 min;

[0081] (3) Heating in a water bath to raise the temperature of the reaction system to 45 °C, slowly add 3.5 mmol of potassium persulfate to the reaction system, and control the temperature of the reaction system to 60 °C, stop heating, stir and keep at this temperature for 25 min, Stirring was stopped and aged for 2 hours to obtain the kaolin modified composite agent, that is, the VAC-AA-MMA (vinyl acetate-acr...

preparation example 2

[0082] Preparation Example 2: Preparation of Modified Quaternized Inorganic Minerals

[0083] Fully mix 5 g of sepiolite and 10 g of illite with a particle size of 100 mesh, then enter the spray chamber through the feed port, spray 0.25 g of atomized silicone oil, and stir at 70°C for 30 minutes, then add water and ethanol Add 0.15 mol N-methyldiphenylamine to the 100 mL solution mixed in equal volumes, and finally add 600 mL of 0.5 mol / L hydrochloric acid aqueous solution, stir for 25 minutes, then filter, and wash the filtered solid with water until neutral , to obtain modified quaternized inorganic minerals.

Embodiment 1

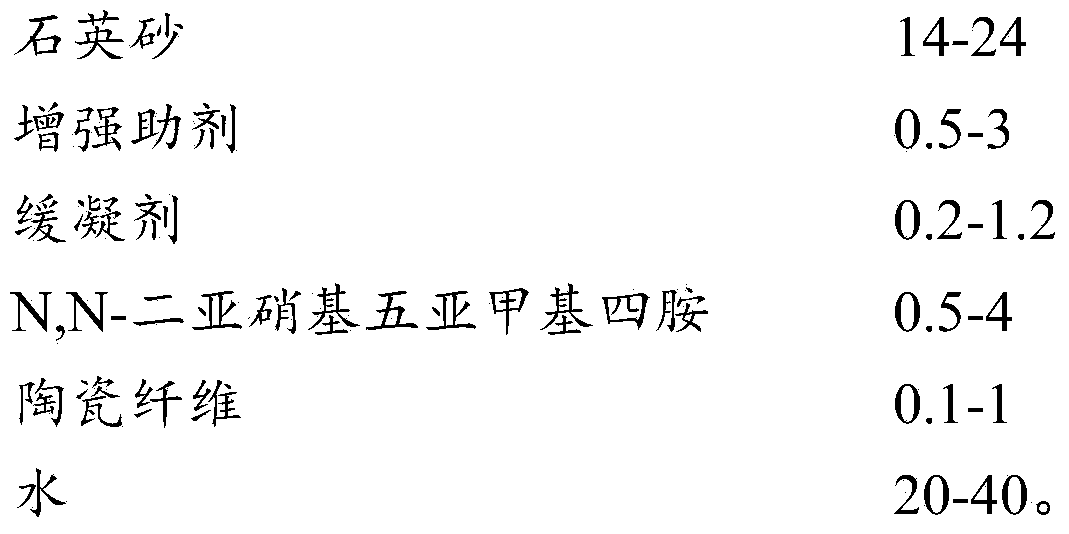

[0085] (1) 35 parts of sulfoaluminate cement, 17 parts of quartz sand, 0.5 part of hydroxypropyl methylcellulose ether, 1.2 parts of cationic neoprene latex, 3.5 parts of kaolin modified composite agent obtained in Preparation Example 1, 2 parts Bisphenol A type epoxy resin, 1.5 parts of the compound of structural formula (I), 5 parts of the modified quaternized inorganic mineral obtained in Preparation Example 2 and 30 parts of water were mixed, and heated to 45° C. and stirred for 15 minutes to obtain a mixture I;

[0086] (2) Mix 2 parts of imidazole, 1.5 parts of CF901 general-purpose silicone defoamer, 1.5 parts of reinforcing additives, 0.8 parts of retarder, 0.5 parts of N, N-dinitrosopentamethylenetetramine and 1 part of The ceramic fibers are mixed and stirred evenly to obtain mixture II;

[0087] (3) Put mixture I and mixture II into a disperser and disperse evenly, then cool down to room temperature to obtain the cement-based decoration slurry of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com