Multielement alloy based on tungsten-potassium alloy and preparation method thereof

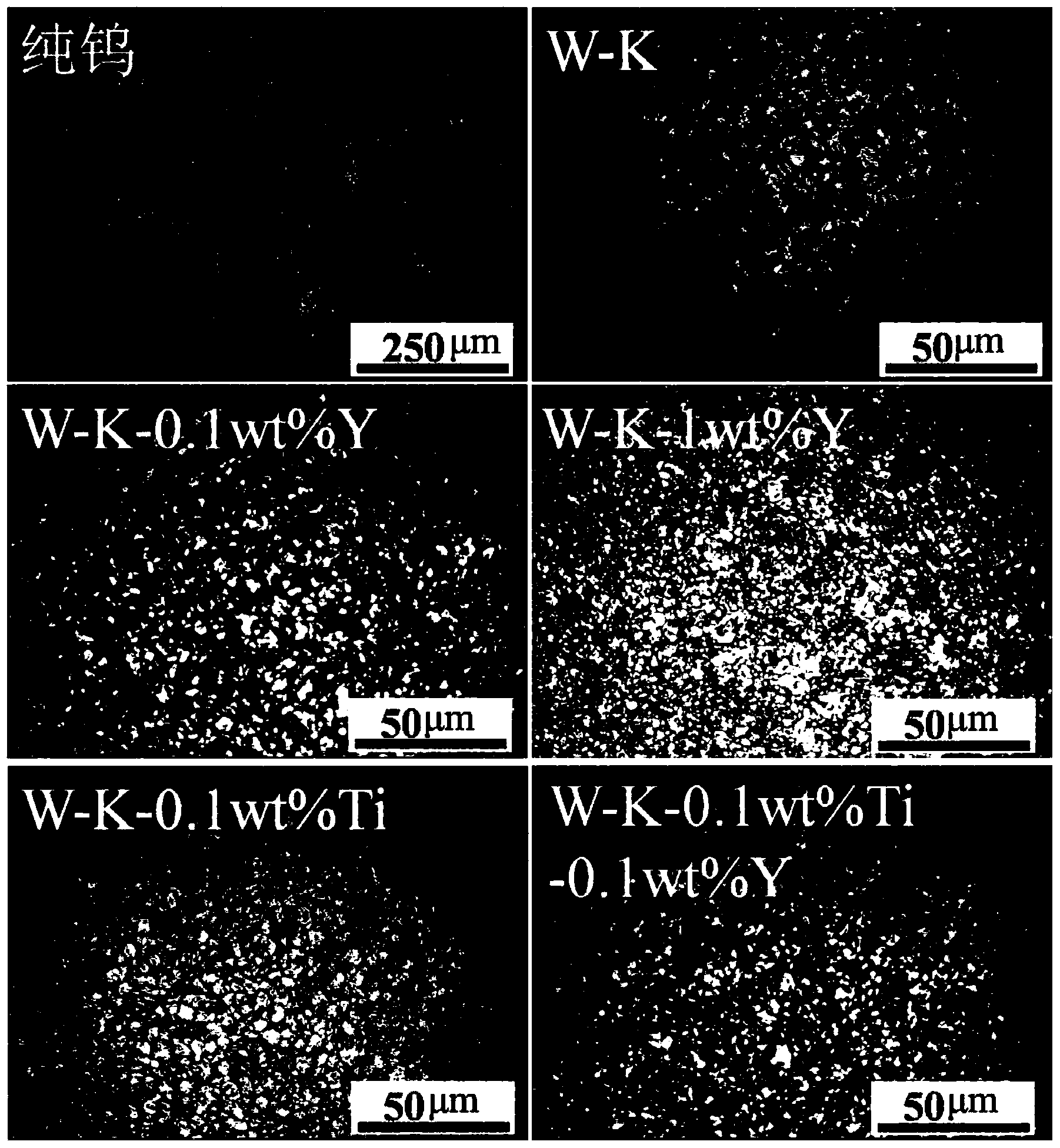

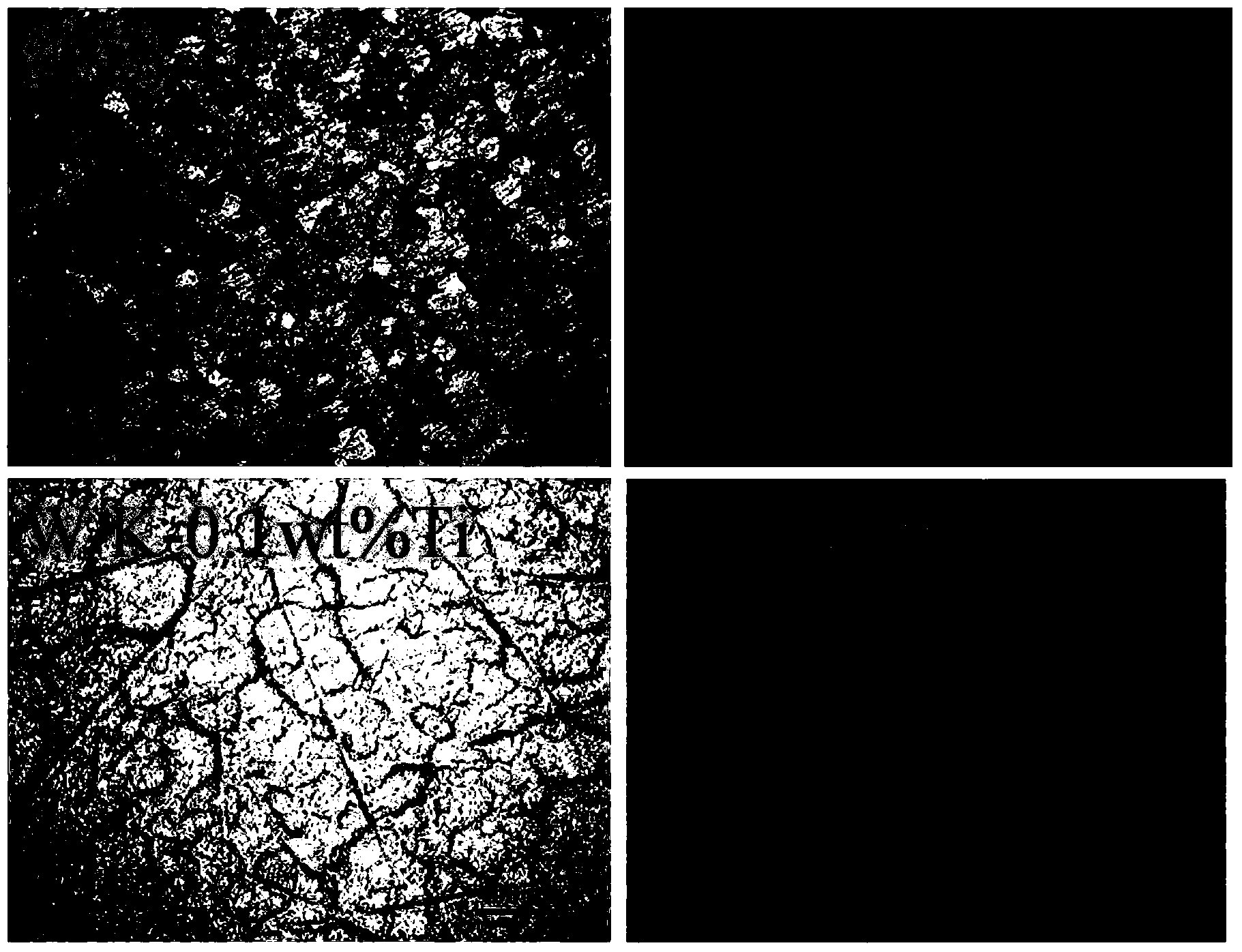

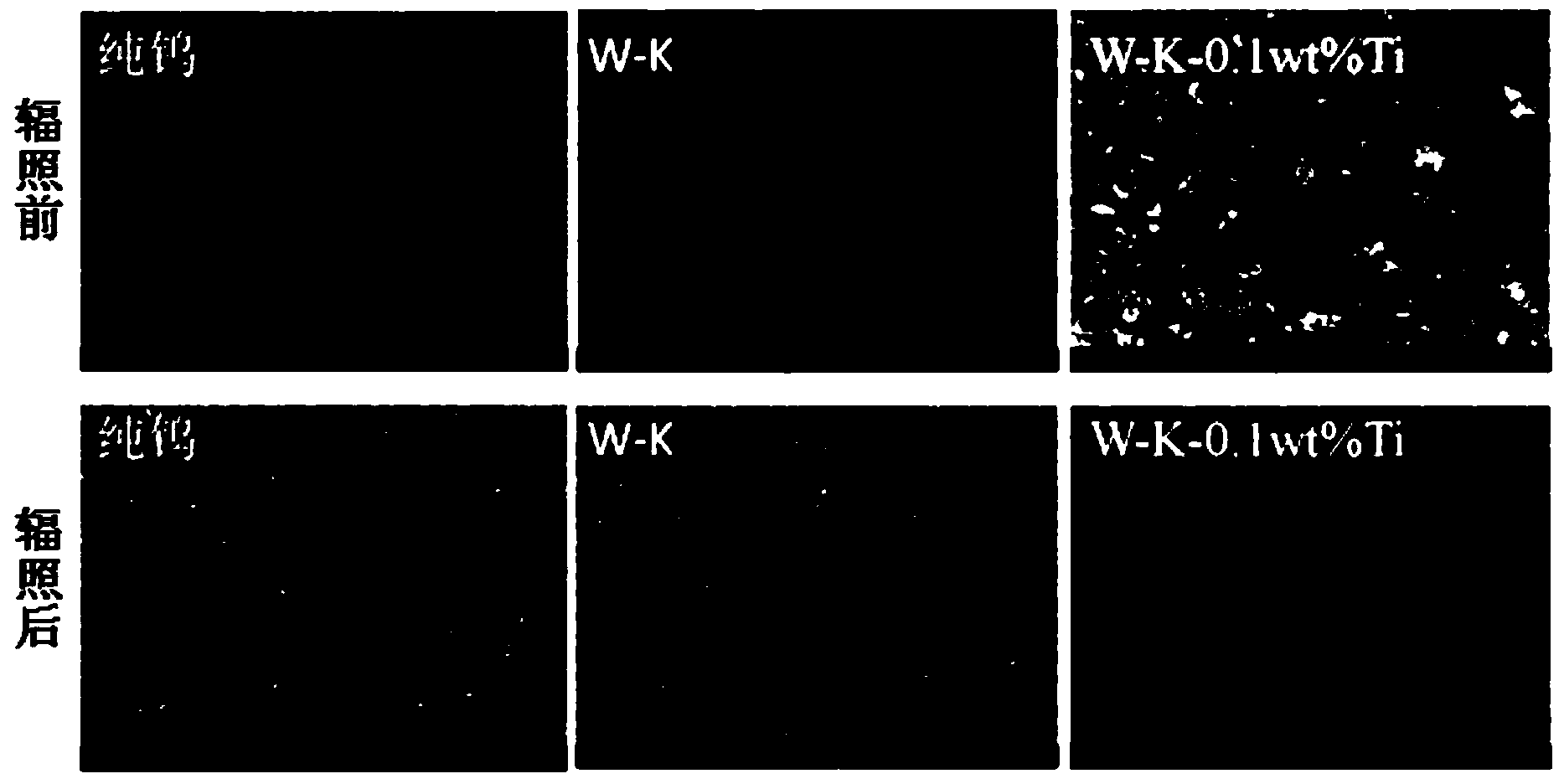

A multi-element alloy and alloy technology, applied in the field of metal materials, can solve the problems that the performance cannot fully meet the service requirements of the fusion demonstration reactor, the radiation resistance performance of the W-K alloy is not excellent, and the thermal shock resistance needs to be improved, so as to achieve excellent radiation resistance. performance, improving mechanical properties and radiation resistance, and the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) High energy ball milling of W-K-0.1wt% Ti alloy powder

[0027] In this embodiment, W-K alloy powder and Ti powder are used as raw materials, and the content of K in the W-K alloy powder is 0.007wt%.

[0028] Unpack the W-K alloy powder and Ti powder in an ultra-low oxygen glove box, then use an electronic balance with an accuracy of 0.001g to weigh 159.840g of W-K alloy powder and 0.160g of Ti powder, and then put a vacuumable cemented carbide ball mill jar Put it into the ultra-low oxygen glove box, add the weighed W-K alloy powder and Ti powder into the ball mill jar, then weigh the cemented carbide grinding balls in the ultra-low oxygen glove box and add them to the ball mill jar, and grind the balls The mass ratio of the mass of W-K alloy powder and Ti powder to the total mass of Ti powder is 5:1, among which, the mass ratio of grinding balls with a diameter of 10mm to a diameter of 6mm is 1:2; The technical indicators for hypoxic glove box work are: the oxyge...

Embodiment 2

[0044] (1) High energy ball milling of W-K-0.1wt% Y alloy powder

[0045] In this embodiment, W-K alloy powder and Y powder are used as raw materials, and the content of K in the W-K alloy powder is 0.007wt%.

[0046] Unpack the W-K alloy powder and Y powder in an ultra-low oxygen glove box, then use an electronic balance with an accuracy of 0.001g to weigh 159.840g of W-K alloy powder and 0.160g of Y powder, and then put the vacuumable cemented carbide ball mill jar Put it into the ultra-low oxygen glove box, add the weighed W-K alloy powder and Y powder into the ball milling jar, then weigh the cemented carbide grinding balls in the ultra-low oxygen glove box and add them to the ball milling jar, and grind the balls The mass ratio of the mass of W-K alloy powder and Y powder to the total mass of Y powder is 5:1, and the mass ratio of the balls with a diameter of 10mm to 6mm is 1:2; The technical indicators for hypoxic glove box work are: the oxygen content is less than 0.1p...

Embodiment 3

[0060] (1) High energy ball milling of W-K-1wt%Y alloy powder

[0061] In this embodiment, W-K alloy powder and Y powder are used as raw materials, and the content of K in the W-K alloy powder is 0.007wt%.

[0062] Unpack the W-K alloy powder and Y powder in an ultra-low oxygen glove box, then use an electronic balance with an accuracy of 0.001g to weigh 158.410g of W-K alloy powder and 1.598g of Y powder, and then put the vacuumable cemented carbide ball mill jar Put it into the ultra-low oxygen glove box, add the weighed W-K alloy powder and Y powder into the ball milling jar, then weigh the cemented carbide grinding balls in the ultra-low oxygen glove box and add them to the ball milling jar, and grind the balls The mass ratio of the mass of W-K alloy powder and Y powder to the total mass of Y powder is 5:1, and the mass ratio of the balls with a diameter of 10mm to 6mm is 1:2; The technical indicators for hypoxic glove box work are: the oxygen content is less than 0.1ppm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com