Soybean meal-based adhesive for wood and preparation method thereof

A technology of adhesives and soybean meal, which is applied in the field of soybean meal-based adhesives for wood and its preparation, can solve the problems of prolonged curing time, increased difficulty of production process, and increased production cost, so as to increase the water-resistant handover performance, increase the added value of products, and save The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

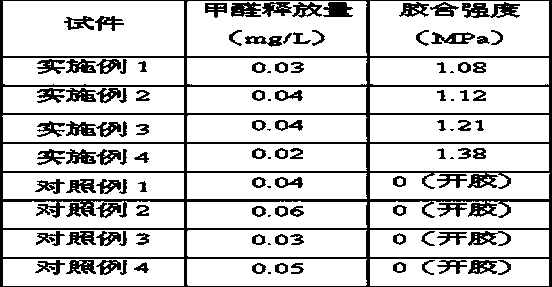

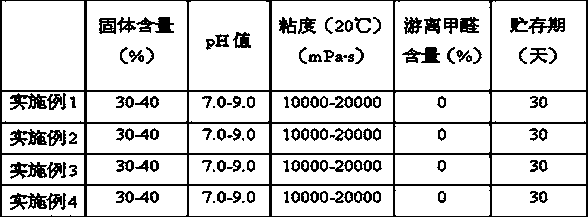

Examples

Embodiment 1

[0027] A soybean meal-based adhesive for wood, prepared from the following raw materials by weight:

[0028] Demineralized water 68kg

[0029] Sodium dodecylbenzenesulfonate 1 kg

[0030] Defatted Soy Protein Powder 26kg

[0031] Cross-linking enhancer 3 kg

[0032] Sodium Benzoate 2kg

[0033] A preparation method of the above-mentioned soybean meal-based adhesive for wood, comprising the following steps:

[0034] 1) Weigh each raw material according to the above weight ratio;

[0035] 2) Add all the demineralized water, soy protein powder and sodium dodecylbenzenesulfonate into the reaction kettle equipped with agitator, thermometer and condensing device, and stir evenly;

[0036] 3) Heat in a water bath to 40-45°C and keep warm for 3 hours;

[0037] 4) The temperature of the reactant is lowered to 30°C to obtain a uniform soy protein mucus;

[0038] 5) Add the enhancer to the obtained soybean protein mucilage, mix well, and then add sodium benzoate to make the soybea...

Embodiment 2

[0043] A soybean meal-based adhesive for wood, prepared from the following raw materials by weight:

[0044] Demineralized water 64 kg

[0045] Sodium dodecylbenzenesulfonate 2 kg

[0046] Defatted Soy Protein Powder 29 kg

[0047] Enhancer 5kg

[0048] Sodium Benzoate 4kg

[0049] A preparation method of the above-mentioned soybean meal-based adhesive for wood, comprising the following steps:

[0050] 1) Weigh each raw material according to the above weight ratio;

[0051] 2) Add all the demineralized water, soy protein powder and sodium dodecylbenzenesulfonate into the reaction kettle equipped with agitator, thermometer and condensing device, and stir evenly;

[0052] 3) Heat in a water bath to 40-45°C and react for 6 hours;

[0053] 4) The temperature of the reactant is lowered to 30°C to obtain a uniform soy protein mucus;

[0054] 5) Add the enhancer to the obtained soybean protein mucilage, mix well, and then add sodium benzoate to make the soybean protein adhesiv...

Embodiment 3

[0059] A soybean meal-based adhesive for wood, prepared from the following raw materials by weight:

[0060] Demineralized water 62 kg

[0061] Sodium dodecylbenzenesulfonate 2 kg

[0062] Defatted Soy Protein Powder 29 kg

[0063] Enhancer 7kg

[0064] Sodium Benzoate 3kg

[0065] A preparation method of the above-mentioned soybean meal-based adhesive for wood, comprising the following steps:

[0066] 1) Weigh each raw material according to the above weight ratio;

[0067] 2) Add all the demineralized water and soybean protein powder into the reaction kettle equipped with agitator, thermometer and condensing device, and stir evenly;

[0068] 3) Heat in a water bath to 65-70°C and react for 5 hours;

[0069] 4) The temperature of the reactant is lowered to 30°C to obtain a uniform soy protein mucus;

[0070] 5) Add the enhancer to the obtained soybean protein mucilage, mix well, and then add sodium benzoate to make the soybean protein adhesive.

[0071] The cross-linki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com