A ternary system relaxor ferrovoltage transistor and its multi-temperature region growth method

A growth method, voltage and electricity technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of crystal quality and performance, and achieve the goals of saving growth time, improving crystal quality, and increasing single crystal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

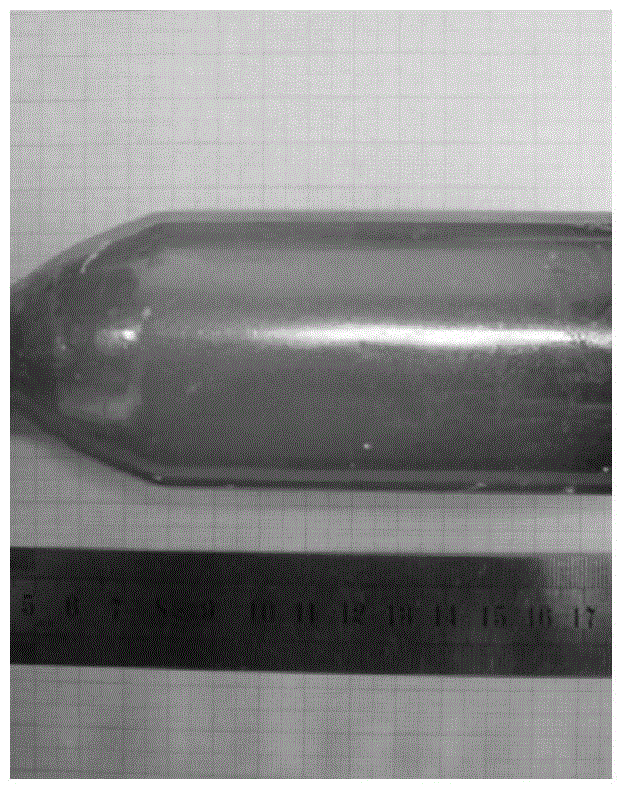

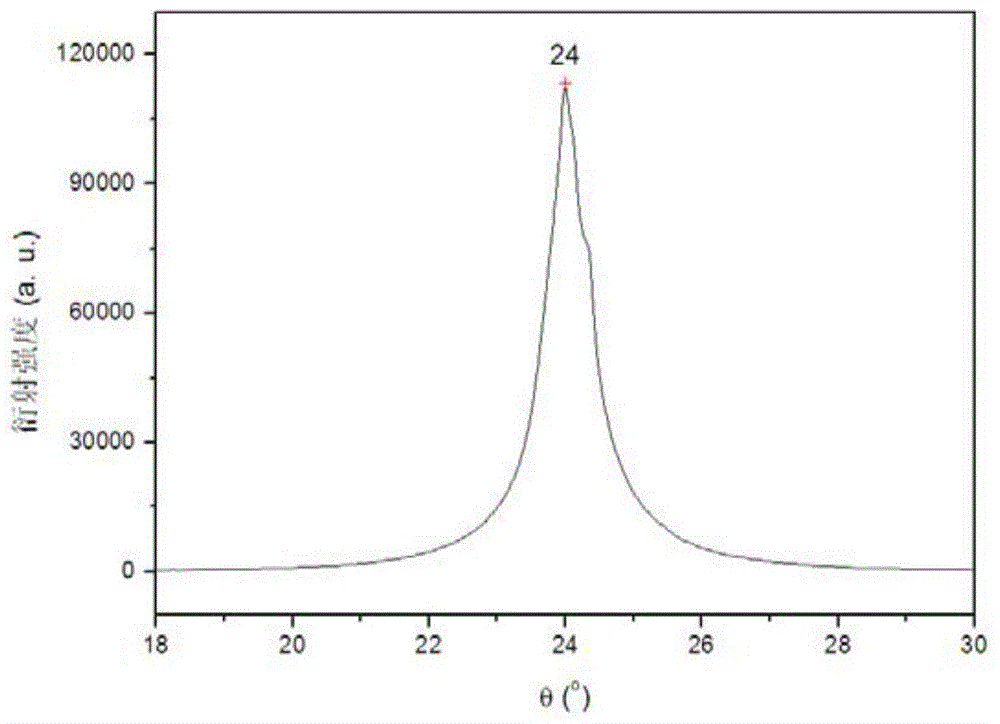

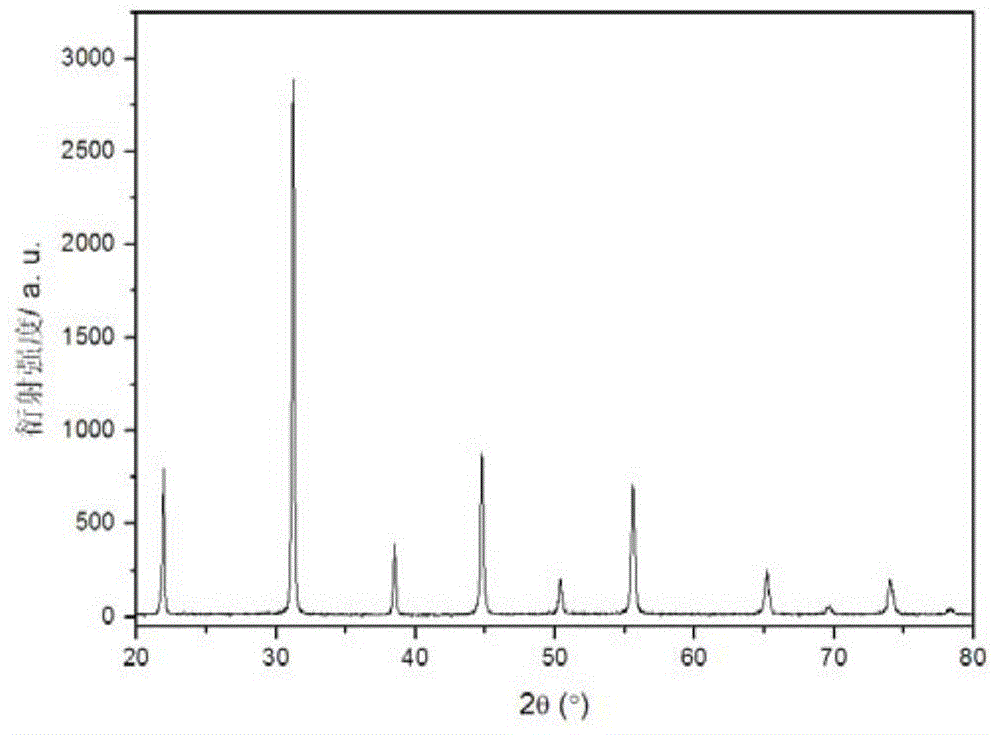

[0040] The multi-temperature region growth technology of the relaxation ferroelectric voltage transistor of the present invention comprises the following steps:

[0041] 1) In order to improve crystal growth efficiency, crucible utilization and reduce costs, refer to the method described in the invention patent with the patent number 201410076798.8 and the publication number CN103866386A, according to the stoichiometric ratio of 0.25PIN-0.42PMN-0.33PT (wherein P refers to Pb , IN is IN powder, MN is MN powder, T is Ti) for batching, and sintering into ceramic raw materials for crystal growth.

[0042] 2) Select the PIMNT single crystal with crystal orientation, make the seed crystal after directional cutting and mechanical polishing, etch the seed crystal with a solution prepared with a volume ratio of HCl:HF=4:1~3:1 for 3~4min, and the etching is completed Then use absolute ethanol to ultrasonically clean for 5 to 10 minutes, then take it out and use N 2 air dry;

[0043] ...

Embodiment 2

[0054] The difference between this embodiment and Example 1 is: according to the stoichiometric ratio of 0.05PIN-0.58PMN-0.37PT (wherein P refers to Pb, IN is IN powder, MN is MN powder, T is Ti) , and sintering synthetic crystal growth ceramic raw materials; the rest of the content is exactly the same as described in Example 1.

[0055] 1) In order to improve crystal growth efficiency, crucible utilization and reduce costs, refer to the method described in the invention patent with the patent number 201410076798.8 and the publication number CN103866386A, according to the stoichiometric ratio of 0.05PIN-0.58PMN-0.37PT (wherein P refers to Pb , IN is IN powder, MN is MN powder, T is Ti) for batching, and sintering into ceramic raw materials for crystal growth.

[0056] 2) Select the PIMNT single crystal with crystal orientation, make the seed crystal after directional cutting and mechanical polishing, etch the seed crystal with a solution prepared with a volume ratio of HCl:HF...

Embodiment 3

[0065] The difference between this embodiment and Example 1 is: according to the stoichiometric ratio of 0.25PIN-0.42PMN-0.33PT (wherein P refers to Pb, IN is IN powder, MN is MN powder, T is Ti) , and sintering synthetic crystal growth ceramic raw materials; the rest of the content is exactly the same as described in Example 1.

[0066] 1) In order to improve crystal growth efficiency, crucible utilization and reduce costs, refer to the method described in the invention patent with the patent number 201410076798.8 and the publication number CN103866386A, according to the stoichiometric ratio of 0.25PIN-0.42PMN-0.33PT (wherein P refers to Pb , IN is IN powder, MN is MN powder, T is Ti) for batching, and sintering into ceramic raw materials for crystal growth.

[0067] 2) Select a PIMNT single crystal with a high melting point crystal orientation, make a seed crystal after directional cutting and mechanical polishing, and corrode the seed crystal with a solution prepared with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com