Crater-type graphical sapphire substrate and preparation method thereof

A technology for patterning sapphire and sapphire substrates, which is applied to the photolithographic process of the patterned surface, optical mechanical equipment, instruments, etc., which can solve the problems of high cost of imprinting templates and restrictions on the commercial application of nanoimprinting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In this embodiment, the sapphire substrate is etched by wet method, and the mask adopts a hard mask. The preparation method of the crater-shaped patterned sapphire substrate of this embodiment includes the following steps:

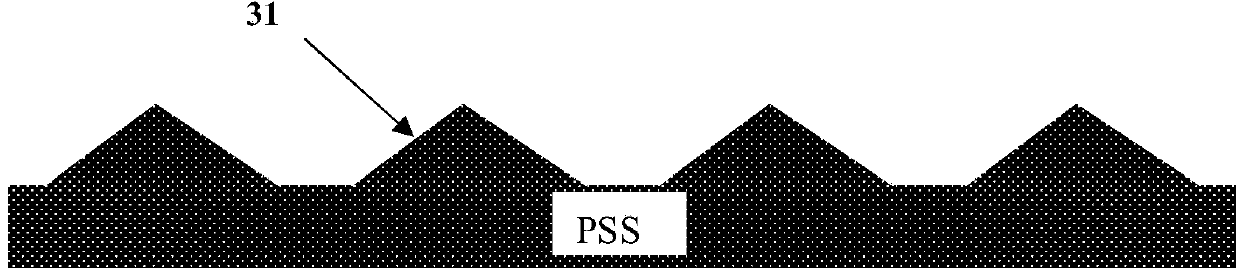

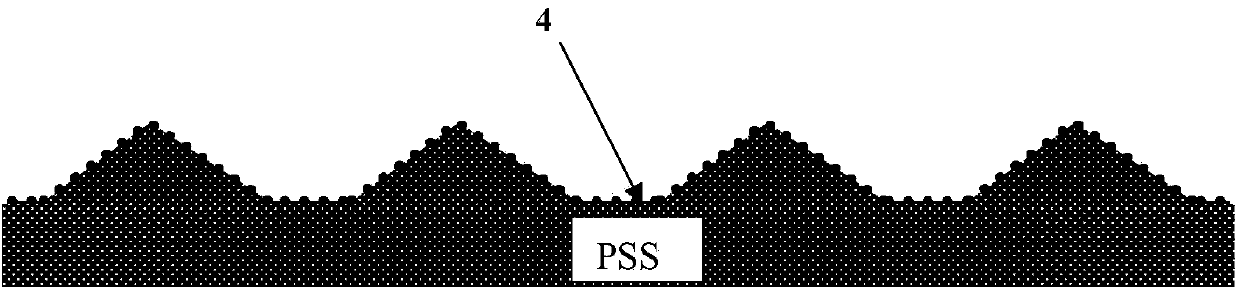

[0060] 1) Surface cleaning and anti-adhesion treatment of commercial PSS: The profile of PSS is as follows figure 1 As shown, the micron PSS pattern 31 on the sapphire substrate is a round bag arranged in a triangle, forming a protrusion array. The bottom diameter of the round bag is 2 microns, the height is 1.5 microns, and the period is 3 microns; Adhesive, wash the PSS and soak it in the anti-adhesive agent for 1 to 10 minutes, and form a trimethylfluorosilane monomolecular anti-adhesive layer 4 on the surface of the PSS after drying, such as figure 2 shown, and volatilize excess molecules.

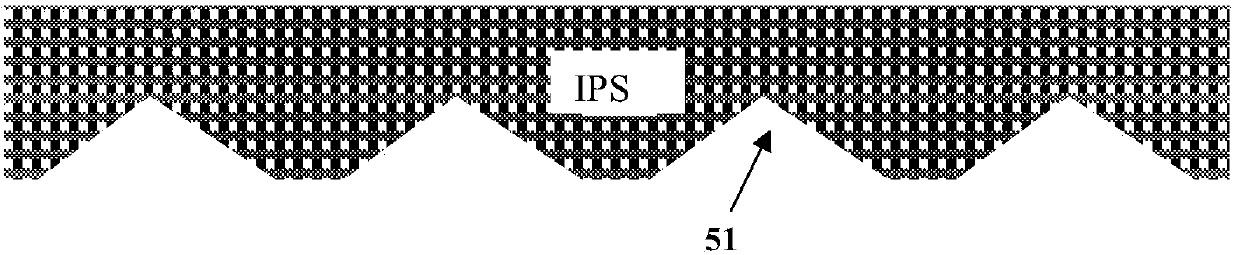

[0061] 2) transfer the micron PSS pattern 31 to the intermediate polymer template IPS by hot embossing: use the hot embossing function of the nanoimprint ...

Embodiment 2

[0069] In this embodiment, the sapphire substrate is etched by dry method, and the mask adopts a hard mask. The preparation method of the crater-shaped patterned sapphire substrate of this embodiment includes the following steps:

[0070] 1) with embodiment one.

[0071] 2) Same as embodiment one.

[0072] 3) successively adopt acetone, ethanol and deionized water to clean the surface of the sapphire substrate 1, after cleaning, vapor-deposit a layer of hard mask 211 with high selective ratio on the surface of the sapphire substrate, such as Ni, Mo, W, etc. The thickness is 100 nanometers; then, spin-coat 150-500 nanometers of nanoimprint adhesive on the hard mask; for hard masks with poor adhesion, it is necessary to spray on the hard mask before coating the nanoimprint adhesive Corresponding tackifier; after spin-coating the nano-imprint adhesive 210, pre-baking under high temperature conditions, the temperature is 100° C., and the time is 5 minutes.

[0073] 4) Same as em...

Embodiment 3

[0078] In this embodiment, the sapphire substrate is etched by a dry method, and nanoimprinting glue is used as a mask. The method for preparing a crater-shaped patterned sapphire substrate in this embodiment includes the following steps:

[0079] 1) Since the nanoimprinting glue is used as a mask in step 5), and the selection ratio of nanoimprinting glue and sapphire etching is small, the annular protrusion needs to be higher than the unembossed glue layer to reach more than 1 micron, so It is necessary to select a PSS with a steep sidewall of the protrusion, an angle of 60°-80° to the substrate, and a height of the protrusion of 1.5-2 microns as the template, and the other is the same as in the first embodiment.

[0080] 2) Same as embodiment one.

[0081] 3) Use acetone, ethanol and deionized water to clean the surface of the sapphire substrate 1 successively. After cleaning, spin-coat a nano-imprint adhesive with a high ratio as a mask on the sapphire substrate. The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com