Carbon network supported zinc oxide nanocrystalline composite material and preparation method and application thereof

A zinc oxide nanocrystal, network loading technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of harsh preparation process of porous carbon with high specific surface area, and achieve good application prospects, Increased conductivity and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

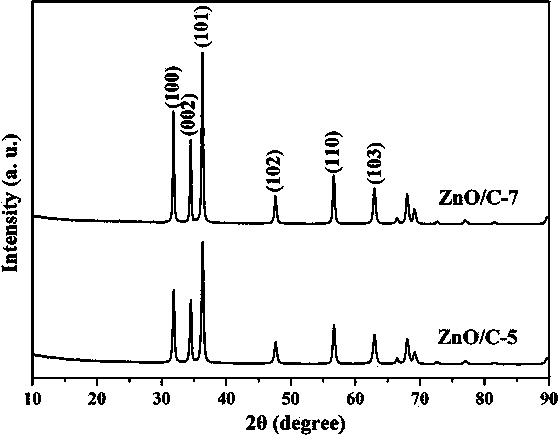

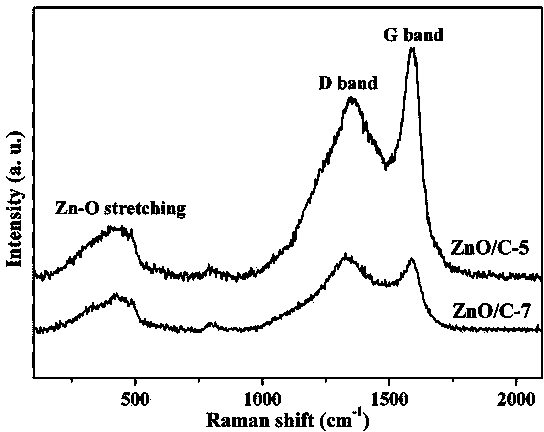

[0028] 1.24 g Zn(NO 3 ) 2 ·6H 2 O was dissolved in a mixed solution of 10 mL oleic acid and 2 mL oleylamine, stirred evenly, and injected into a three-necked flask, and the reaction system was introduced into an inert atmosphere, at 120 o C under reflux for 60 min to remove residual moisture in the reactant and air in the system. Then warm up to 240 oC, and keep warm for 120 min. After the temperature of the system dropped to room temperature, it was centrifuged and washed three times with alcohol. o Dry in a blast oven at C. Put 0.3 g of the dried powder into a tube furnace for carbonization at a temperature of 700 o C, holding time 180 min, heating rate 10 o C / min. The stability of the composite structure carbon network obtained under this condition is average, most of the ZnO is tetrahedral, and a small amount of ZnO is irregular in shape, the size range is about 100-350 nm, the size distribution is wide, and the cycle performance of lithium-ion batteries is good. ...

Embodiment 3

[0030] 1.24 g Zn(NO 3 ) 2 ·6H 2 O was dissolved in the mixed solution of 20 mL oleic acid and 4 mL oleylamine, stirred evenly and poured into a three-necked flask, and the reaction system was introduced into an inert atmosphere, and at 120 o C under reflux for 60 min to remove residual moisture in the reactant and air in the system. Then warm up to 240 o C, and keep warm for 120 min. After the temperature of the system dropped to room temperature, it was centrifuged and washed three times with alcohol. o Dry in a blast oven at C. Put 0.3 g of the dried powder into a tube furnace for carbonization at a temperature of 700 o C, holding time 180 min, heating rate 10 o C / min. Under this condition, the composite structure carbon network obtained has good stability, ZnO crystal shape is irregular, the size range is about 100 nm, and the distribution is relatively uniform. The cycle performance of the lithium-ion battery is average, and the specific capacity performance is goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com