Stable flurbiprofen axetil micro-nano-emulsion and preparation method thereof

A technology of flurbiprofen axetil and micro-nano emulsion, which is applied in the fields of emulsion delivery, medical preparations containing non-active ingredients, medical preparations containing active ingredients, etc. Pain and other problems, to achieve good thermodynamic stability, small and uniform particles, reduce the effect of injection pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

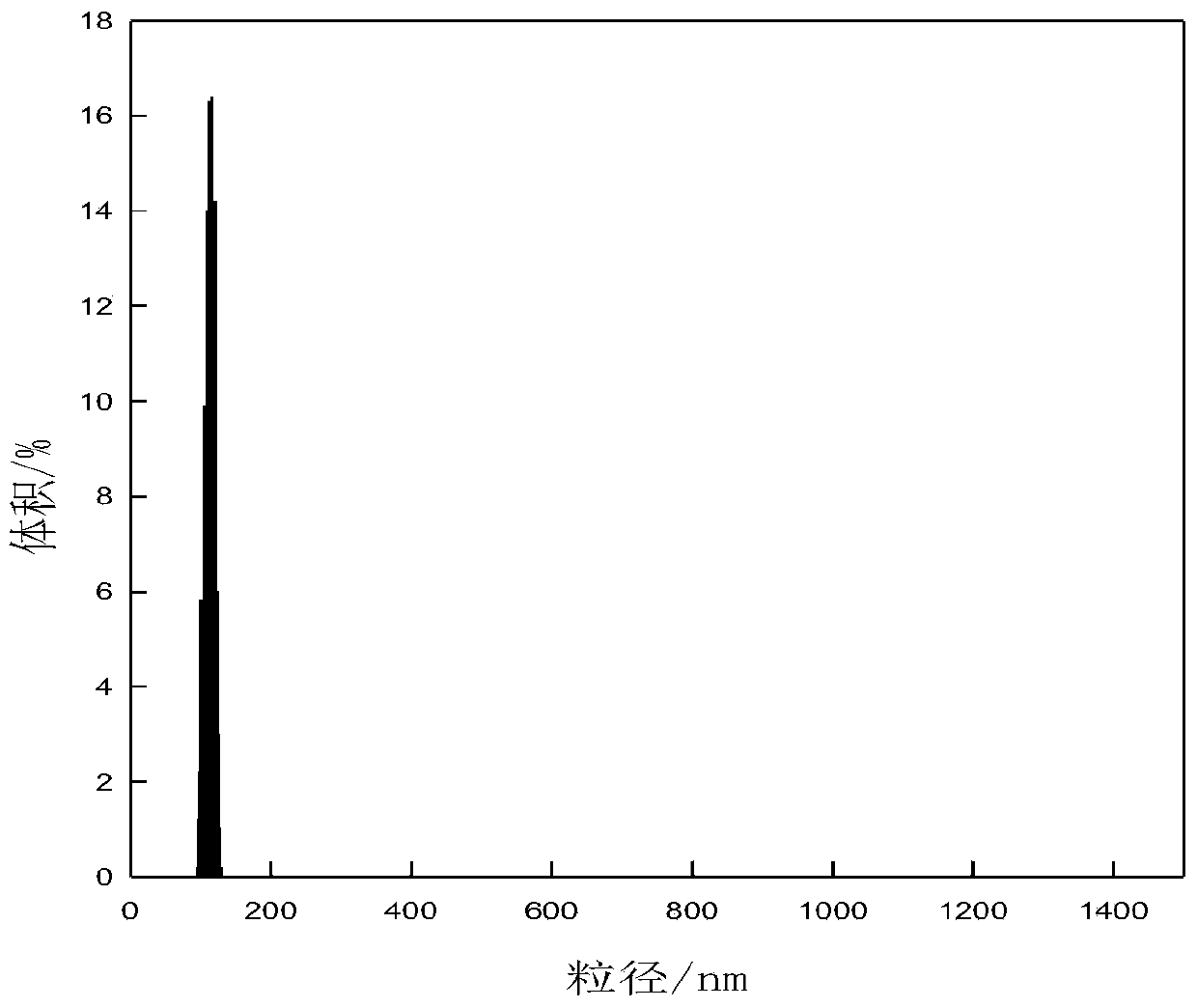

Image

Examples

Embodiment 1

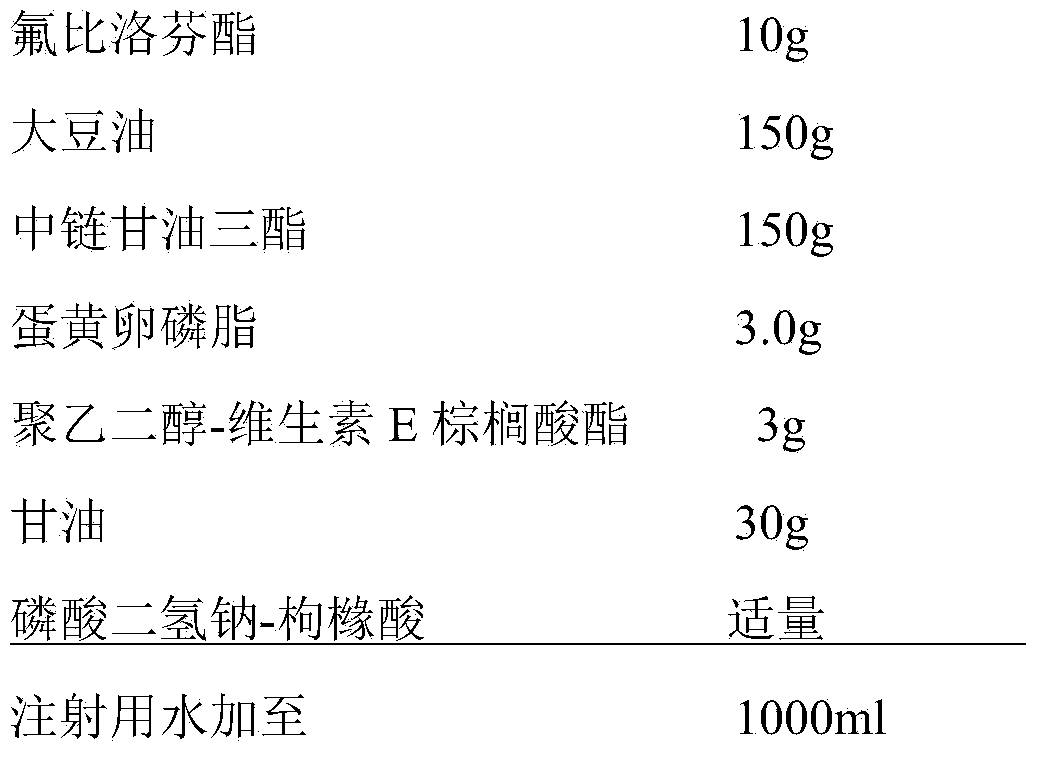

[0039] prescription

[0040]

[0041] Process:

[0042] (1) Preparation of the oil phase: Take 3.0g egg yolk lecithin, 3g polyethylene glycol-tocopherol palmitate, add 150g soybean oil and 150g medium chain triglycerides, and stir at 30°C under nitrogen protection 20min to fully dissolve, then add 10g flurbiprofen axetil, dissolve and mix evenly, as the oil phase;

[0043] (2) Preparation of the water phase: under the conditions of nitrogen protection and a temperature of 30°C, take 500 ml of water for injection, add 30 g of glycerin, and stir to dissolve it as the water phase;

[0044] (3) Preparation of colostrum: under nitrogen protection and temperature 30℃, add step (1) oil phase to step (2) water phase, high-speed shear dispersion, shear speed 10000rpm, time 15 minutes to form Colostrum, and adjust the total amount to 1000ml with water for injection;

[0045] (4) High-pressure homogenization: Under nitrogen protection and a temperature of 30°C, the colostrum obtained in step (3)...

Embodiment 2

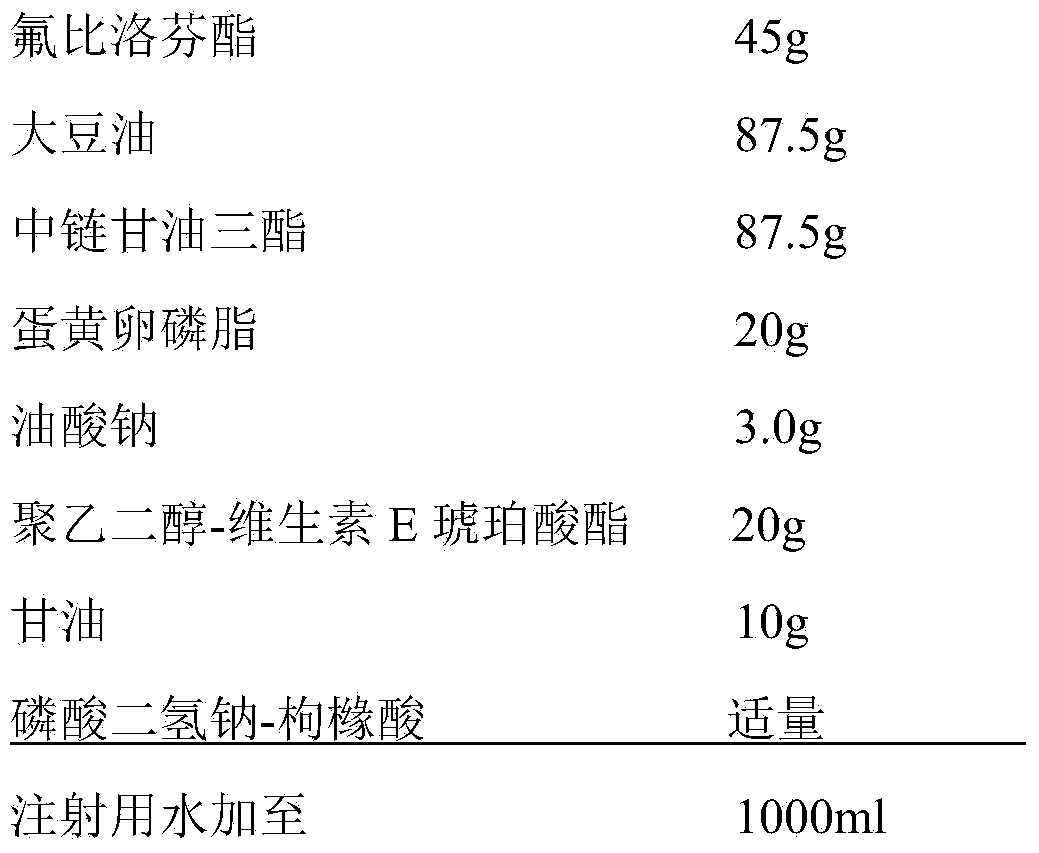

[0049] prescription

[0050]

[0051] Process:

[0052] (1) Preparation of the oil phase: take 20g egg yolk lecithin, 3.0g sodium oleate, 20g polyethylene glycol-tocopherol succinate and add 87.5g soybean oil and 87.5g medium chain triglycerides, in a nitrogen protected Under the conditions, stir at 40°C for 20 minutes to fully dissolve, then add 45g flurbiprofen axetil, dissolve and mix well, as the oil phase;

[0053] (2) Preparation of water phase: Take 500ml of water for injection under the condition of nitrogen protection and temperature of 40°C, add 10g of glycerin, stir to dissolve it, as the water phase;

[0054] (3) Preparation of colostrum: under nitrogen protection and temperature 40℃, add step (1) oil phase to step (2) water phase, high-speed shear dispersion, shear speed 8000rpm, time 35 minutes to form Colostrum, and adjust the total amount to 1000ml with water for injection;

[0055] (4) High-pressure homogenization: Under nitrogen protection and a temperature of 40°C, ...

Embodiment 3

[0058] prescription

[0059]

[0060] Process:

[0061] (1) Preparation of the oil phase: take 11g egg yolk lecithin, 6.0g sodium oleate, 40g polyethylene glycol-tocopherol palmitate and add 25g soybean oil and 25g medium chain triglycerides, under nitrogen protection , Stir at 20°C for 20min to fully dissolve, then add 80g flurbiprofen axetil, dissolve and mix well, as the oil phase;

[0062] (2) Preparation of the water phase: under the condition of nitrogen protection and temperature of 20°C, take 500ml of water for injection, add 50g of glycerin, stir to dissolve it, and serve as the water phase;

[0063] (3) Preparation of colostrum: under the condition of nitrogen protection and temperature of 20℃, add the oil phase of step (1) to the water phase of step (2), high-speed shear dispersion, shear speed 7000rpm, time 40 minutes, and form Colostrum, and adjust the total amount to 1000ml with water for injection;

[0064] (4) High-pressure homogenization: Under the conditions of nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com